Production device and production method of lithium hexafluorophosphate

A technology of lithium hexafluorophosphate and production method, applied in the directions of lithium hexafluorophosphate, separation method, chemical instrument and method, etc., to achieve the effects of reducing moisture, simplifying operation, improving utilization rate and reaction rate

Active Publication Date: 2022-06-10

BEIJING UNIV OF CHEM TECH

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this method is that phosphorus pentafluoride is easy to react with organic solvents, resulting in low product conversion rate, increasing the difficulty of product separation, resulting in waste of some raw materials, and higher requirements for the selection of organic solvents

The disadvantage of this method is that hydrogen fluoride is used, which requires high corrosion protection for equipment.

Method used

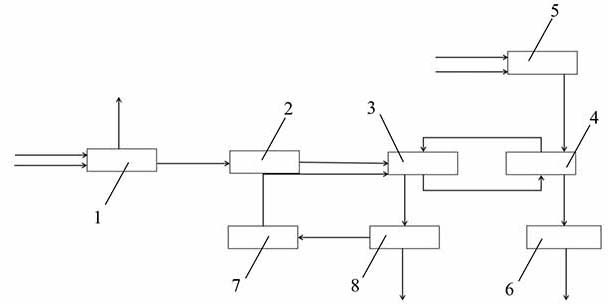

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

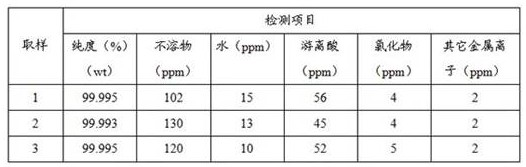

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Login to View More

Abstract

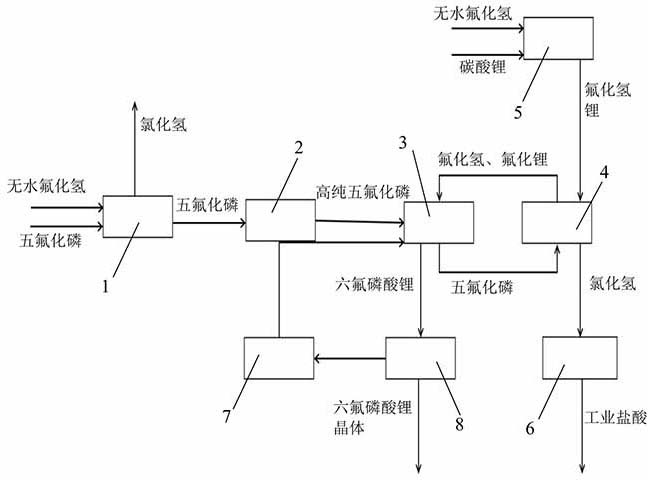

The invention relates to a production device and a production method of lithium hexafluorophosphate, and the method comprises the following steps: introducing phosphorus pentachloride and anhydrous hydrogen fluoride into a replacement reaction tank for reaction, and introducing the generated phosphorus pentafluoride into a synthesis reaction kettle; introducing anhydrous hydrogen fluoride and lithium carbonate into an acidification pool to prepare a hydrogen fluoride and lithium fluoride mixed solution; and feeding the phosphorus pentafluoride and the mixed solution into a circular reaction kettle for reaction, feeding excessive hydrogen fluoride and lithium fluoride into a synthesis reaction kettle for synthesis of lithium hexafluorophosphate, and feeding the generated product liquid into a crystallization tank for crystallization. And returning the rest mother liquor to a rectification refining section through a pump to participate in the reaction again. The hydrogen chloride gas generated by the circular reaction kettle can be absorbed to prepare industrial hydrochloric acid. The purity of the lithium hexafluorophosphate crystal produced by the system reaches 99% or above, and the moisture (mass fraction) can be controlled to be 5 * 10 <-6 > or below.

Description

technical field [0001] The invention relates to the technical field of chemical synthesis, and more specifically relates to a production device and production method of lithium hexafluorophosphate. Background technique [0002] Lithium hexafluorophosphate is a lithium battery electrolyte salt widely used at present. Its structural formula is LiPf6, which is white crystal or powder, and it is easy to decompose when exposed to air or wet steam. [0003] Because lithium hexafluorophosphate is easy to decompose when it encounters air or wet steam, the production process of lithium hexafluorophosphate usually requires no contact with air or gas, and the synthesis temperature is low, which requires more cryogenic energy consumption. [0004] At present, the production methods of lithium hexafluorophosphate mainly include gas-solid reaction method, hydrogen fluoride solvent method, organic solvent method and ion exchange method, among which hydrogen fluoride solvent method is the m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J19/00B01D3/00C01D15/00

CPCB01J19/00B01J19/0013B01D3/009C01D15/005B01J2219/00006C01P2006/80C01P2006/82Y02E60/10

Inventor 李群生

Owner BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com