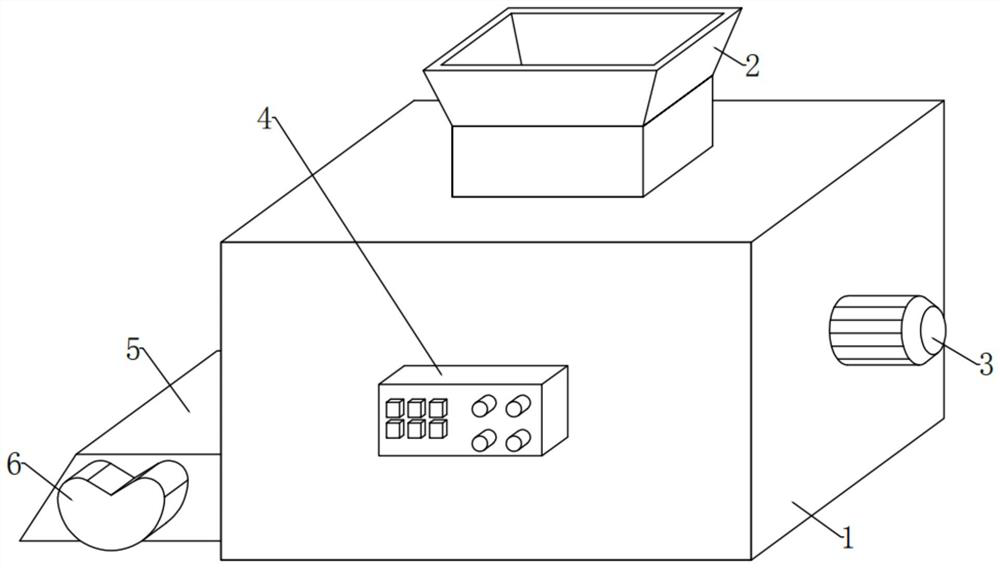

Plastic particle injection molding preheating treatment equipment

A technology of plastic particles and preheating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

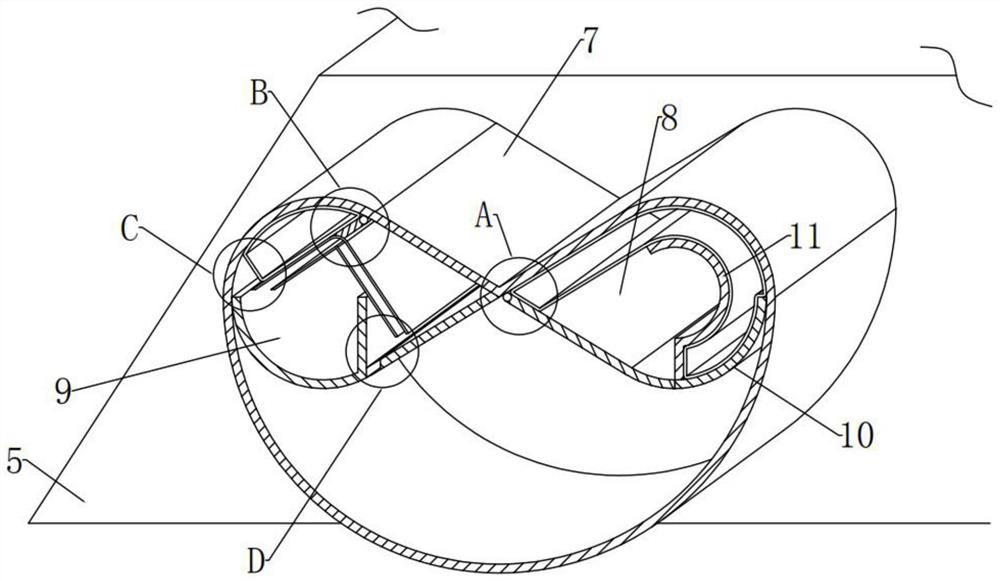

Method used

Image

Examples

Embodiment 1

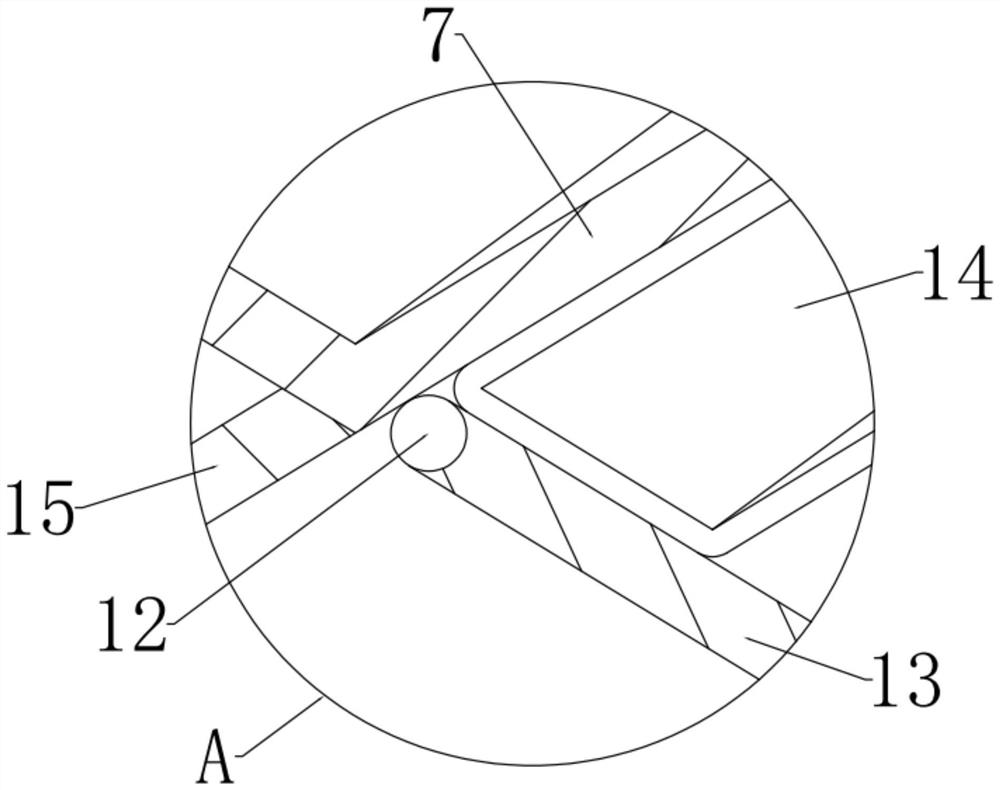

[0036] In the embodiment of the present invention, the material storage plate 16 is in the shape of a "U" groove with a left arc and a right straight line. Clean water is pre-installed between the inner wall of the material storage plate 16 and the front and rear inner walls of the dustproof case 7, and the pre-installed water level of the clean water is The line is flat with the top of the material storage plate 16, and there is a through groove through up and down between the right bottom end of the material storage plate 16 and the middle part of the left bottom end of the support plate 15;

[0037] In the embodiment of the present invention, the fixed plate 18 is in the shape of a short straight plate with low left and right high, and the fixed plate 18 is in an inclined static equilibrium state with an angle of 34° with the horizontal plane under normal conditions, and the material guide groove 19 is hollow inside and closed front and back. , the inverted "V" shape that ru...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com