Ink supply circulation system capable of preventing ink from precipitating

A circulation system and ink supply technology, applied in transportation, packaging, printing, dissolution, etc., to achieve the effect of improving clogging, reducing accumulation, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

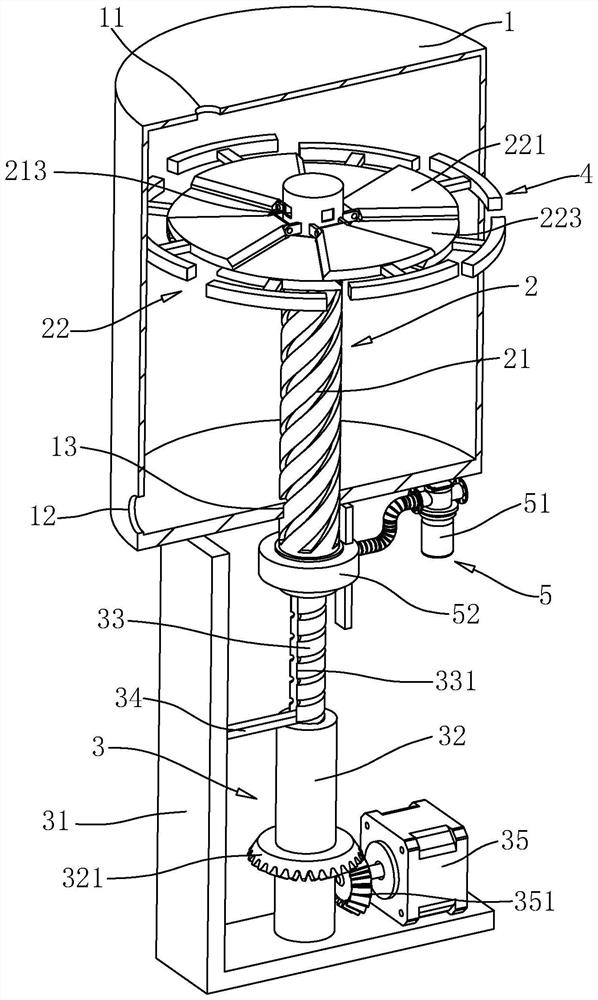

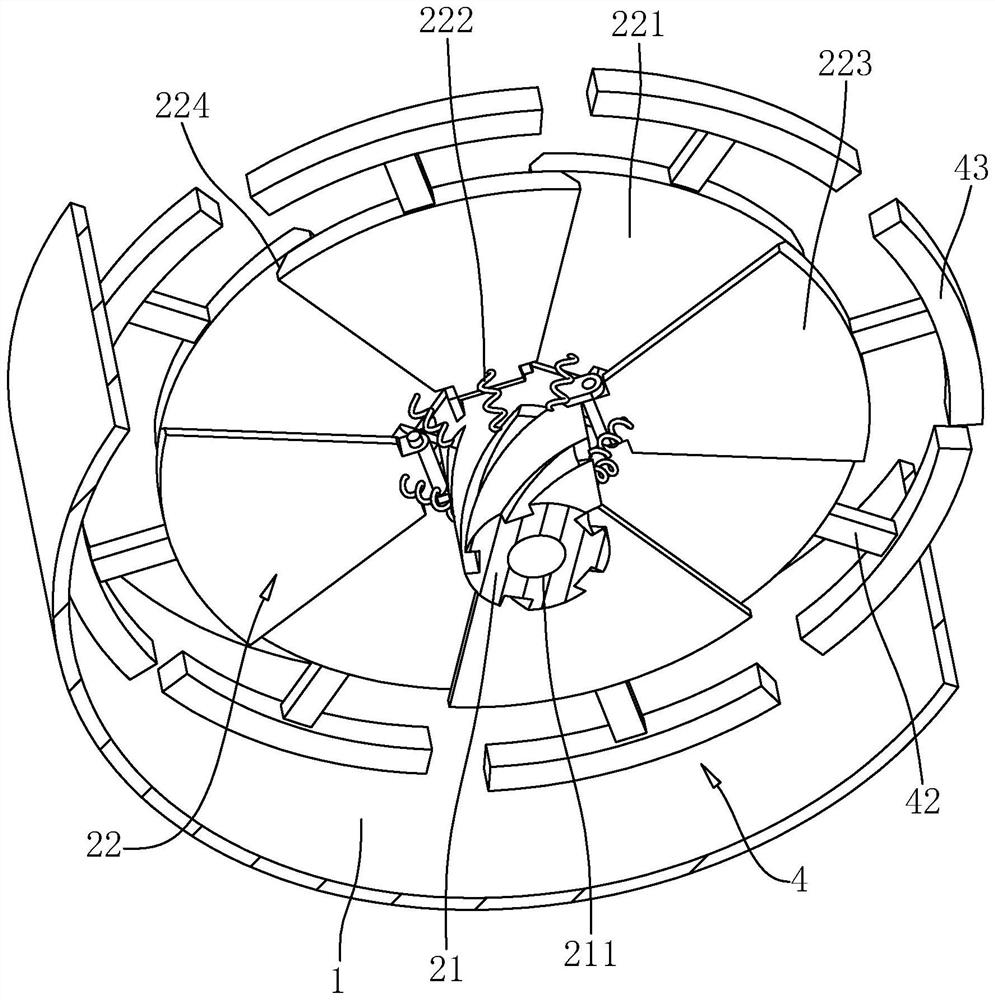

[0037] refer to image 3 and Figure 4 , the first fan-shaped plate 221 and the second fan-shaped plate 223 are equipped with scraping parts 4, and the side walls of the first fan-shaped plate 221 and the second fan-shaped plate 223 away from the jacking rod 21 are provided with installation grooves 225 to install The scraping part 4 on the first fan-shaped plate 221 is an example, and the scraping part 4 includes a connecting spring 41, a connecting rod 42 and a scraping plate 43; the connecting spring 41 is fixedly connected on the inner wall of the mounting groove 225; the connecting rod 42 slides Move and place in the mounting groove 225, the connecting rod 42 is fixedly connected with the connecting spring 41, the connecting rod 42 extends to the outside of the first fan-shaped plate 221, and the first fan-shaped plate 221 drives the connecting rod 42 to move; the scraping plate 43 is fixedly connected to the The connecting rod 42 is far away from the end face of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com