Whole-course flow self-regulation uninterrupted drainage drain valve

A trap and flow technology, applied in steam traps, mechanical equipment, etc., to achieve long service life, easy manufacturing, and reduced maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

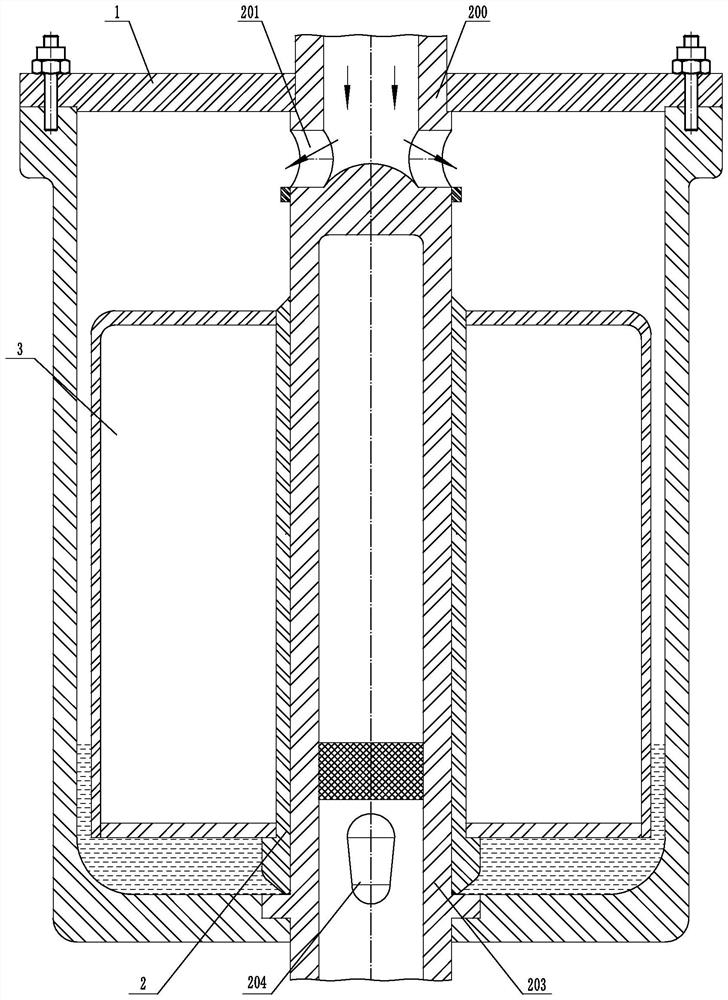

[0050] attached figure 1 As shown, at this time, the condensed water in the inner cavity of the valve body 1 is at the lowest position, the valve core sleeve 2 is closely attached to the dead discharge pipe 203 with the valve seat, and at the same time, the condensed water seals off the sealing pair.

[0051] second embodiment

no. 2 example

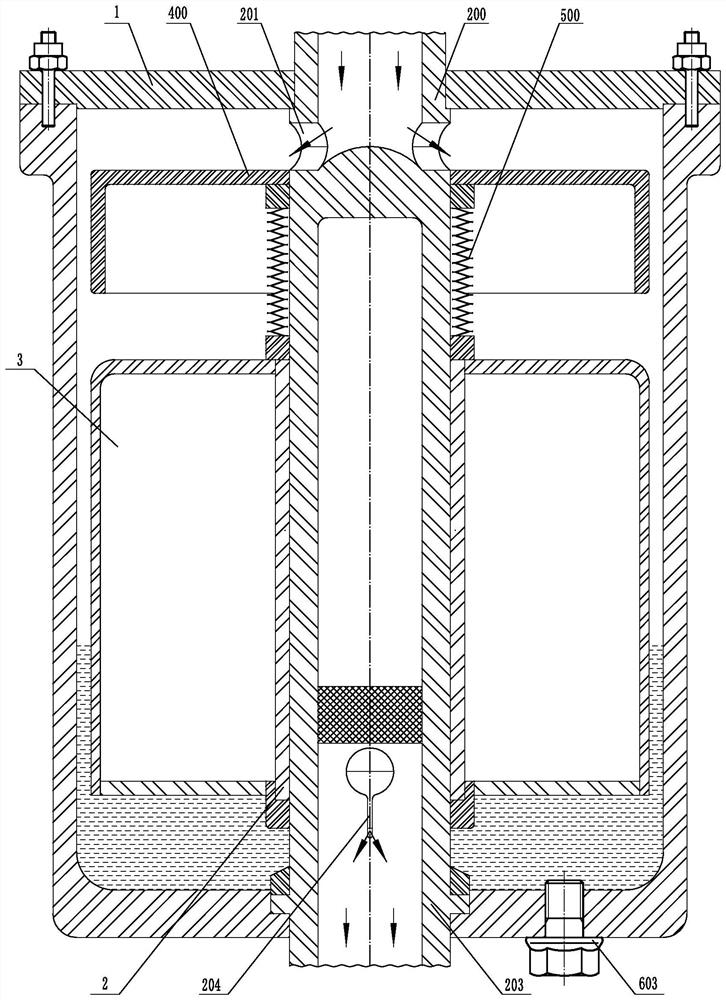

[0053] attached figure 2 As shown, at this time, the condensed water in the inner cavity of the valve body 1 is at a middle-low level, the lower end of the valve core sleeve 2 leaves the valve seat, a small amount of condensed water is discharged, and the pressure in the inner cavity of the valve body 1 presses the sealing cover plate 6 .

[0054] third embodiment

no. 3 example

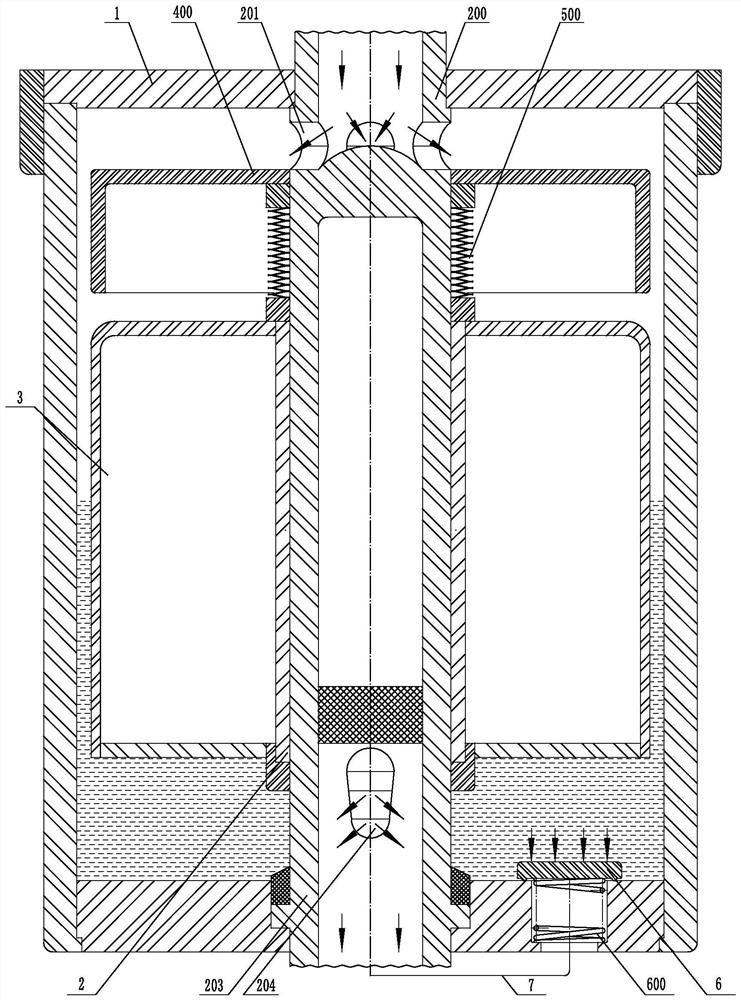

[0056] attached image 3 As shown, at this time, the condensed water in the inner cavity of the valve body 1 is at a high level, and a large amount of condensed water is discharged. At the same time, the pressure in the inner cavity of the valve body 1 presses the sealing cover plate 6 .

[0057] attached Figure 4 As shown, at this time, the pipe network is in three states: 1. The pipe network has just stopped working, and the inner cavity of the pipe network loses pressure. There is a vacuum in the pipe network; 2. The pipe network is in a non-working state; 3. The pipe network has just started to work, and the compression spring A600 still lifts the sealing cover 6, and a small amount of pressure appears in the inner cavity of the pipe network, blowing off the air in the inner cavity of the pipe network , exhaust gas and residual condensate.

[0058] Fourth embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com