A high-efficiency elevator guide rail installation accuracy calibration equipment

A technology for elevator guide rails and installation accuracy, which can be used in measuring devices, surveying and navigation, and measuring inclination, etc., and can solve problems such as large calibration errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

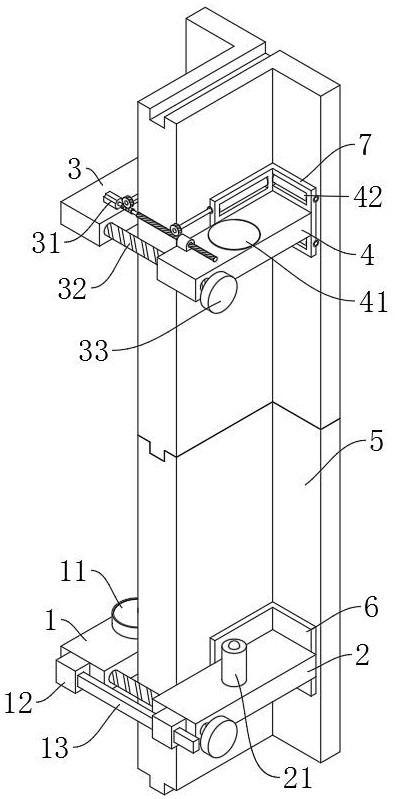

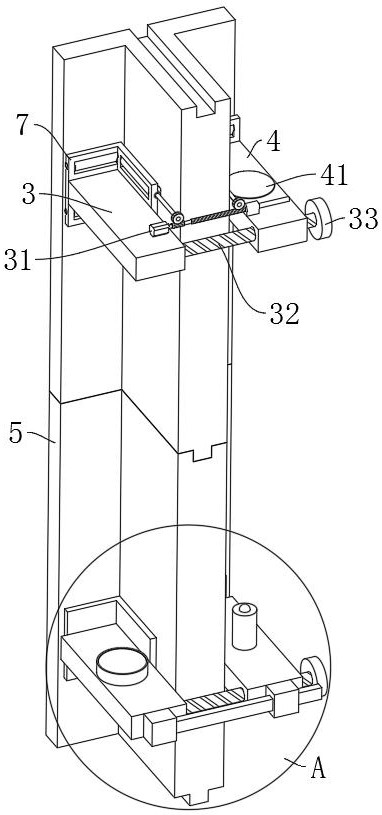

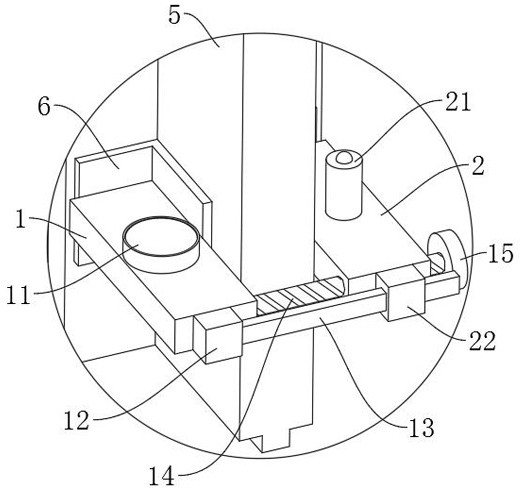

[0029] refer to Figure 1-5 , a high-efficiency elevator guide rail installation accuracy calibration equipment, comprising a guide rail body 5, and also includes: a first lower support plate 1 and a first upper support plate 3 arranged on one side of the guide rail body 5, and the first lower support plate 1 is fixed on the A bubble level 11 is connected; the second lower support plate 2 and the second upper support plate 4 are arranged on the other side of the guide rail body 5, the second lower support plate 2 is fixedly connected with a laser transmitter 21, and the second upper support plate 4 A light display plate 43 corresponding to the laser transmitter 21 is fixedly connected on the upper surface, and a scale is provided on the light display plate 43; two first angle irons 6 are fixedly connected to the first lower support plate 1 and the second lower support plate 2 respectively. , the first angle iron 6 is in close contact with the surface of the guide rail body 5; ...

Embodiment 2

[0033] refer to Figure 1-5 , a high-efficiency elevator guide rail installation accuracy calibration equipment, basically the same as Embodiment 1, further: the first fastening member includes a first threaded rod 14, and one end of the first threaded rod 14 is rotatably connected to the first lower support plate 1, the other end of the first threaded rod 14 is fixedly connected to the first knob 15, the first threaded rod 14 is threadedly connected to the second lower support plate 2, and the first lower support plate 1 is fixedly connected with a fixing block 12, the fixing block The guide rod 13 is fixedly connected to the 12, the second lower support plate 2 is fixedly connected to the first limit block 22, the guide rod 13 is slidably connected to the first limit block 22, and the two first angle irons 6 are respectively connected with the first limit block 22. The lower support plate 1 and the second lower support plate 2 are vertically connected, and the laser transmit...

Embodiment 3

[0036] refer to Figure 1-5 , a high-efficiency elevator guide rail installation accuracy calibration equipment, basically the same as Embodiment 1, further: the second fastening member includes a second threaded rod 32, and one end of the second threaded rod 32 is rotatably connected to the first upper support plate 3, the other end of the second threaded rod 32 is fixedly connected to the second knob 33, the second threaded rod 32 is threadedly connected to the second upper support plate 4, and the two second angle irons 7 are respectively used with the first upper support plate 3. It is vertically connected with the second upper support plate 4, the second upper support plate 4 is provided with a through hole 42, the light display plate 43 is fixedly connected in the through hole 42, the light display plate 43 is fixedly connected with a convex lens 41, and the driving assembly includes the motor 31 is fixed Connected to the first upper support plate 3, the output end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com