Split portable air cushion bed

A portable, air-cushion bed technology, applied in the field of air-cushion beds, can solve the problems of dislocation and shaking, increase the workload of nurses, and poor use effect, and achieve the effects of stable massage, improved massage effect, and reduced nurse workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

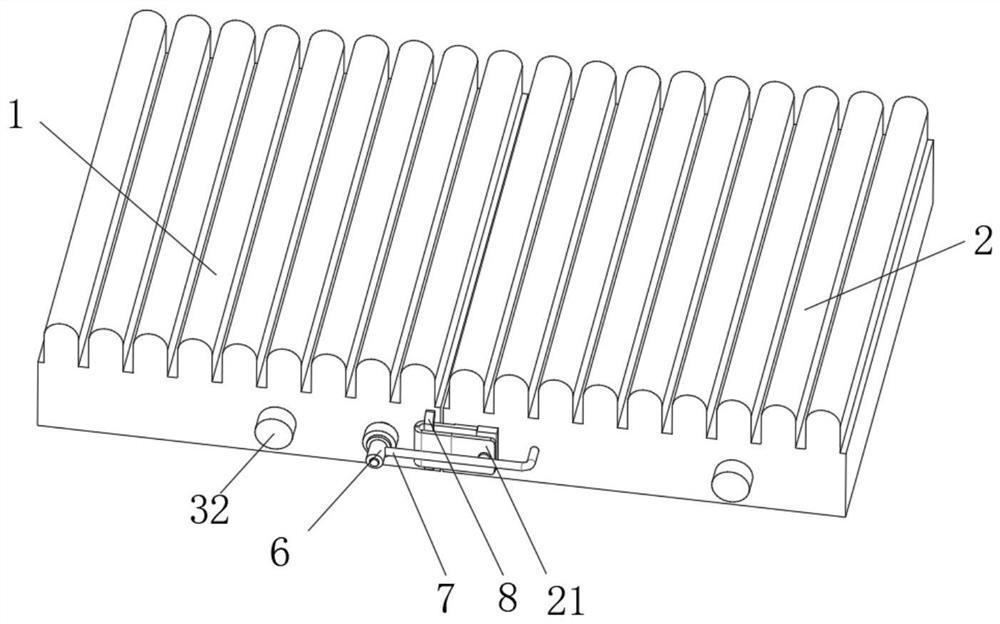

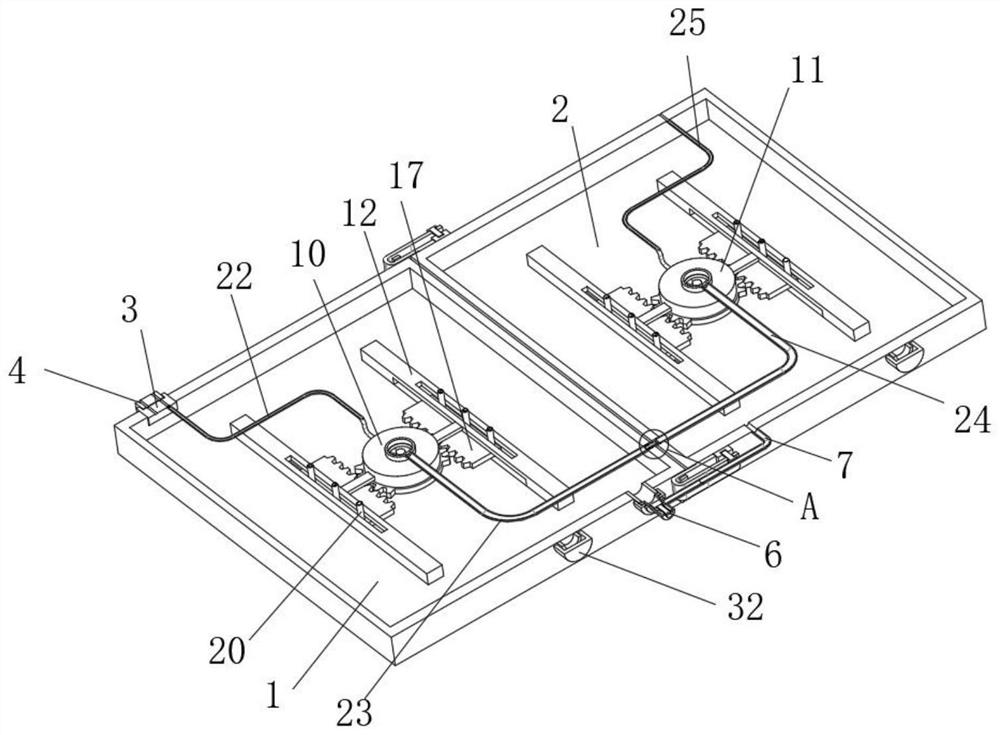

[0041] The first embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, the connecting belt 212 of the clamping mechanism 21 is passed around the cassette 8, and the fixing bolts 213 are threaded through the connecting belt 212 to the fixing plate 211, so that the sealing mechanism 6 on the end surface of the communication pipe 7 is threaded with the fixing pipe 5. Sleeve, supply air to the air distribution sleeve 4, so that the supplied air directly enters the No. 1 mattress 1 and gradually enters the No. 2 mattress 2 through the communication pipe 7. After the inflation is completed, switch the air supply direction, The gas enters the cover plate 105 of the No. 1 rotating mechanism 10 through the No. 1 pipe 22, so that the gas entering the cover plate 105 pushes the blades 103 to rotate, so that the rotating shaft 102 rotates, and the rotation of the rotating shaft 102 drives the missing gear 104 to rotate, The missing gear 104 dri...

no. 3 example

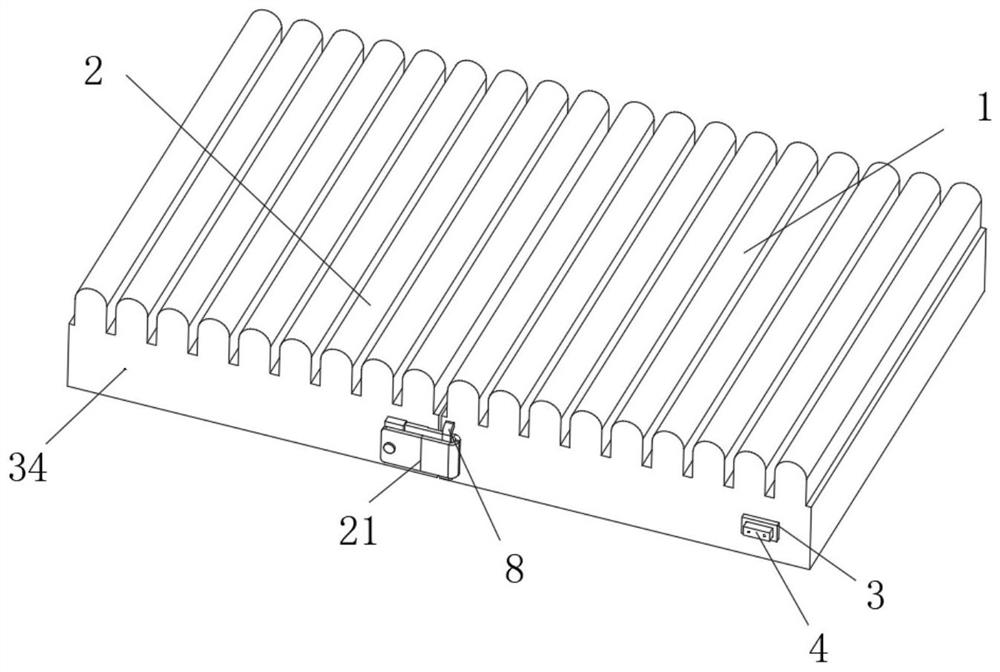

[0051] The third embodiment: as figure 1 , image 3 and Figure 10 As shown, during inflation, the threaded sleeve 61 of the sealing mechanism 6 is threadedly sleeved on the end surface of the fixed tube 5, after the interior of the mattress 1 is filled with air, the continuously rushing gas pushes the interior of the sealing mechanism 6 the sealing plug 64, so that the sealing plug 64 pushes the No. 4 spring 65 to compress, and the air enters the inside of the No. 2 mattress 2 through the communication pipe 7, and continues to inflate the No. 2 mattress 2. When the No. 2 mattress 2 is inflated Then, unscrew the threaded sleeve 61, and quickly make the unscrewed threaded sleeve 61 and the side pipe thread on the front of the No. 2 mattress 2 to be sleeved, so that the split-type No. 2 mattress 2 is taken out separately, and the No. 1 bed The sealing cover 32 on the front face of the pad 1 is sleeved into the fixed pipe 5 to perform supplementary inflation, so that the mattre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap