Fabricated building grouting teaching practical training equipment cleaning method and device

A cleaning device and assembled technology, applied in cleaning methods and utensils, chemical instruments and methods, space navigation equipment, etc., can solve the problems of low service life, obstructing the flow of slurry, waste of resources, etc., so as to improve service life and reduce Failure rate, the effect of reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

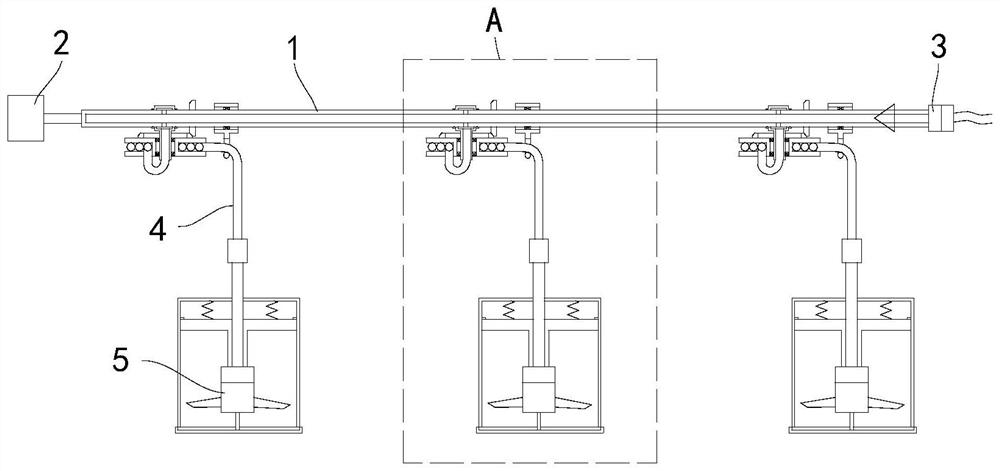

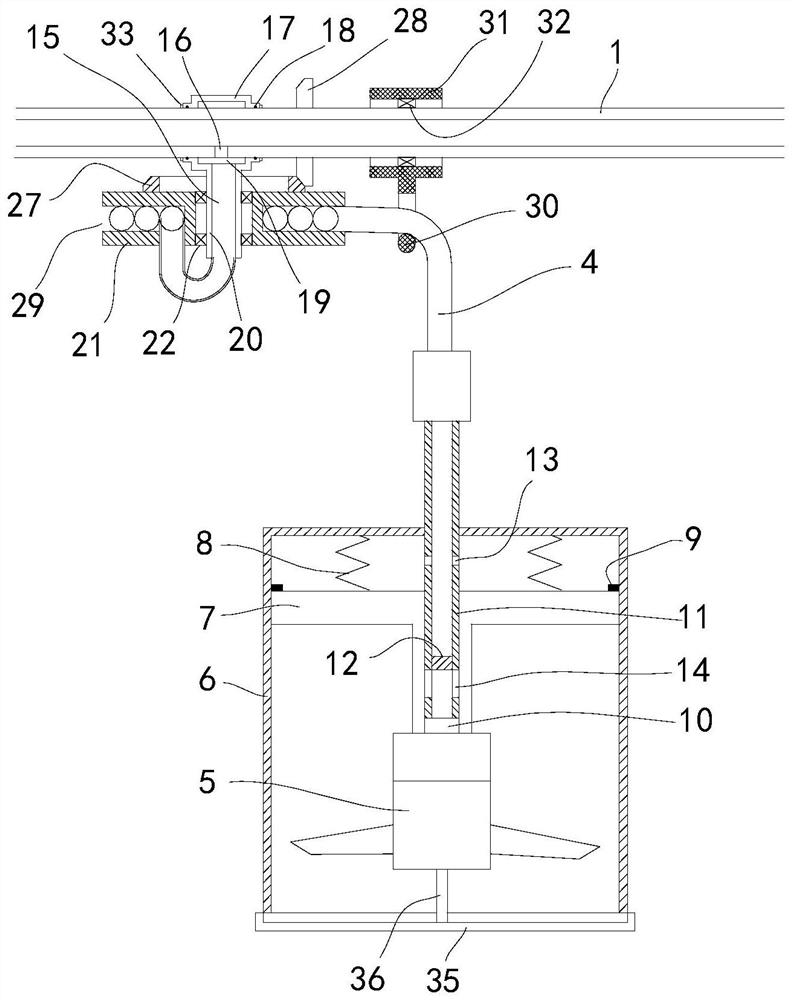

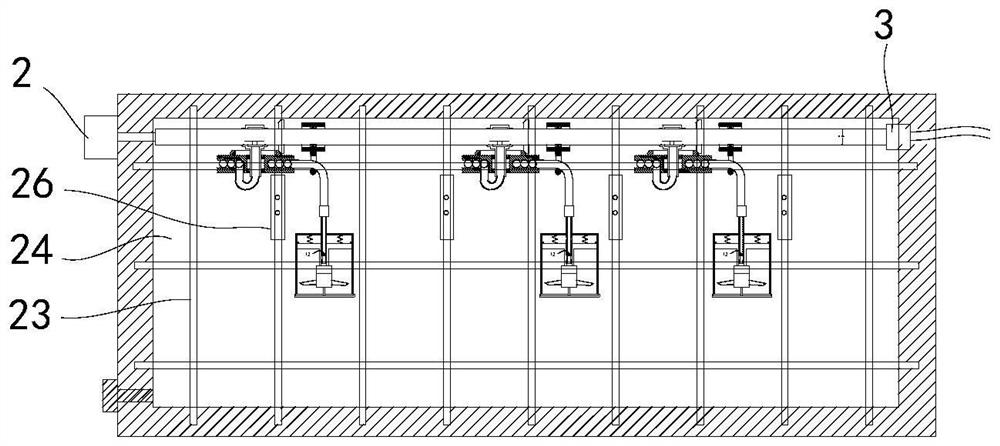

[0024] Example. The cleaning method of prefabricated building grouting teaching and training equipment is to set a plurality of rotating nozzles 5 in the cavity 24 of the teaching and training equipment, and firstly shoot a circumferentially rotating water flow through the rotating nozzles 5, so that the water in the cavity 24 on the same height area is The slurry is impacted by the water flow, and then all the slurry in the cavity 24 is impacted by the water flow by means of the reciprocating lifting and rotating nozzle 5 .

[0025] The cleaning device for realizing the above cleaning method includes a rotating pipe 1, one end of the rotating pipe 1 is closed, the closed end of the rotating pipe 1 is provided with a motor 2, the other end of the rotating pipe 1 is provided with a rotary joint 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com