Battery preheating control method and device suitable for direct current charging pile

A DC charging pile and pre-heating technology, which is applied in charging stations, secondary batteries, transportation and packaging, etc., can solve the problems of battery pre-heating, reduce life attenuation, and ensure charging safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

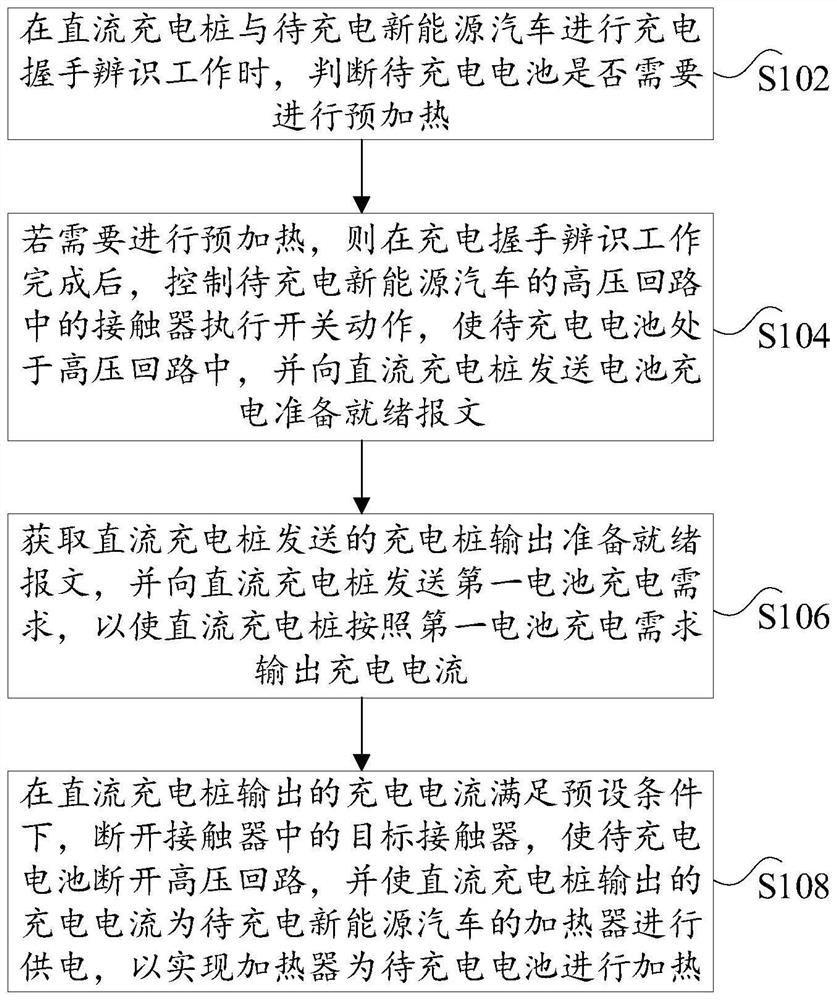

[0043] According to an embodiment of the present invention, an embodiment of a control method for battery preheating suitable for a DC charging pile is provided. It should be noted that the steps shown in the flowchart of the accompanying drawings can be executed in a set of computer executable instructions, for example. and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that herein.

[0044] figure 1 It is a flow chart of a control method for battery preheating suitable for DC charging piles according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0045] Step S102, when the DC charging pile and the to-be-charged new energy vehicle perform the charging handshake identification work, determine whether the to-be-charged battery needs to be preheated;

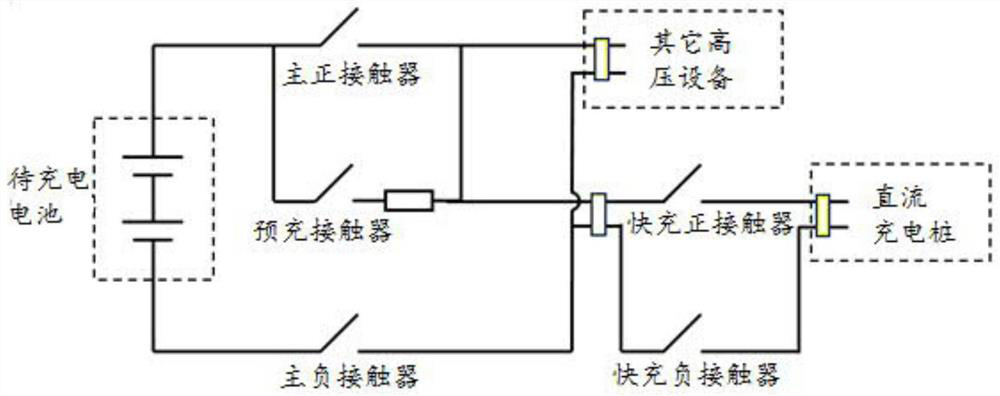

[0046] The control method for battery preheating applicable to the D...

Embodiment 2

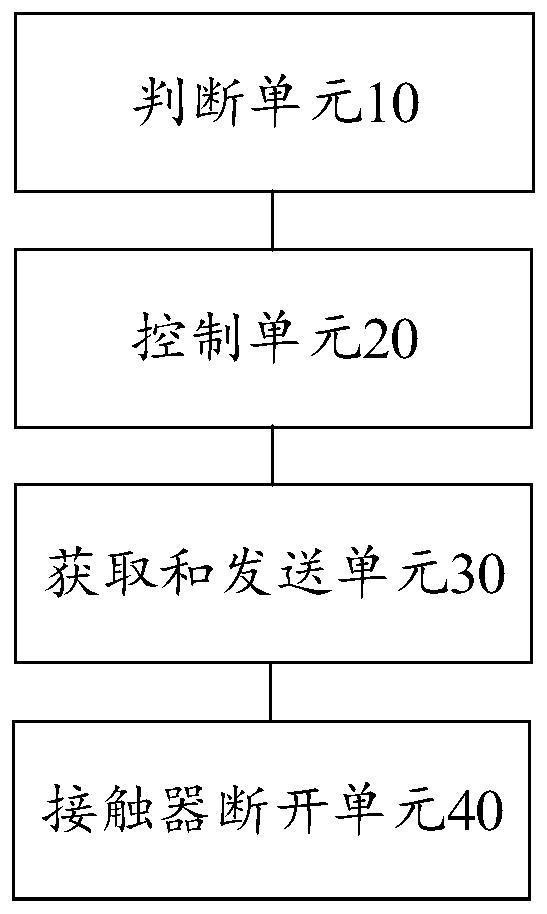

[0079] The embodiment of the present invention also provides a control device for battery preheating suitable for DC charging piles, and the control device for battery preheating suitable for DC charging piles is mainly used to implement the The control method for the battery preheating of the DC charging pile is described below in detail for the control device suitable for the battery preheating of the DC charging pile provided by the embodiment of the present invention.

[0080] image 3 It is a schematic diagram of a control device suitable for battery preheating of DC charging piles according to an embodiment of the present invention, such as image 3 As shown, the device mainly includes: a judgment unit 10, a control unit 20, an acquisition and transmission unit 30 and a contactor disconnection unit 40, wherein:

[0081] The judgment unit is used to judge whether the battery to be charged needs to be preheated when the DC charging pile and the new energy vehicle to be ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com