High-efficiency elastic triangular sand frame for flat plate type part forming and using method of high-efficiency elastic triangular sand frame for flat plate type part forming

A high-efficiency, flat-panel technology, which is applied to the parts of grinding machine tools, grinding slides, grinding racks, etc., can solve the problems of poor adjustment of the triangular sand frame structure, and the inability to fully apply walls with different angles, etc., to achieve The effect of using the effect is remarkable and the scope of application is expanded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

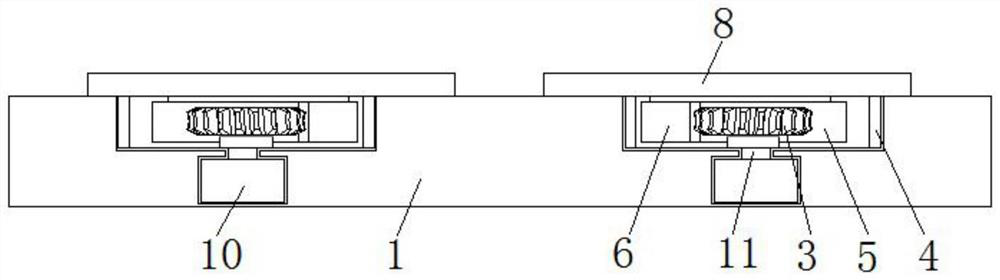

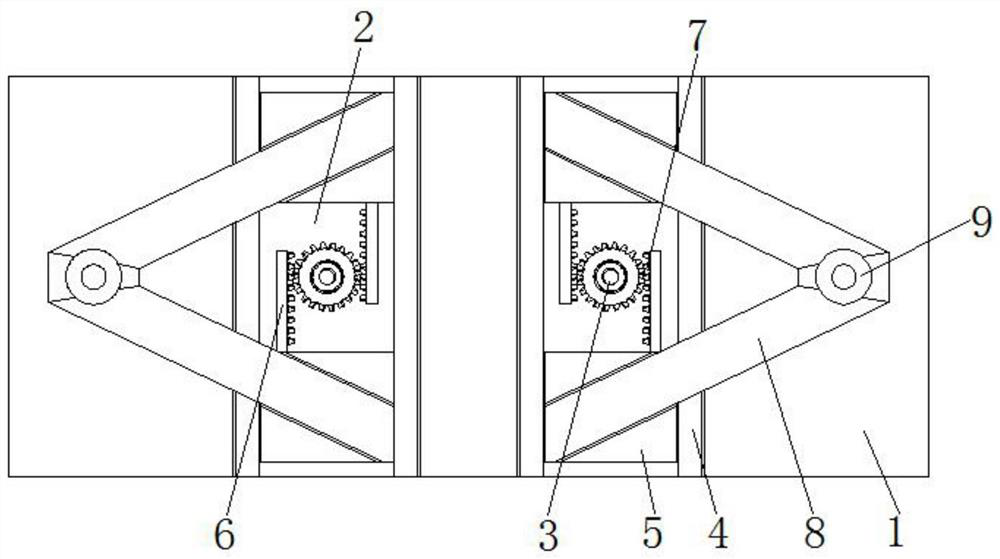

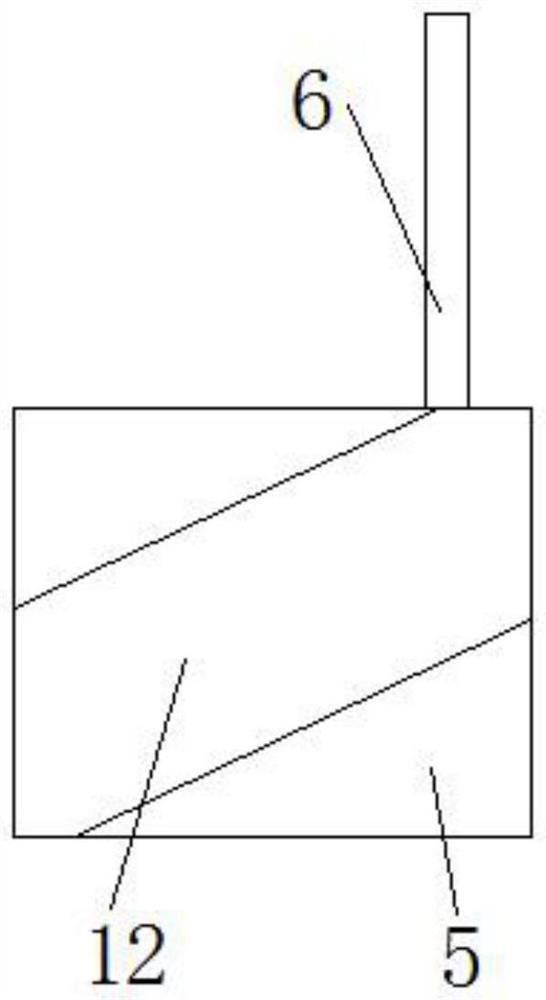

[0022] refer to Figure 1-3 A high-efficiency elastic triangular sand frame for forming flat panel components, comprising a fixed table 1, and straight grooves 2 are respectively opened along the width direction at corresponding positions on both sides of the table surface of the fixed table 1, and the straight grooves 2 located on both sides are arranged in parallel. The front and rear sides of the inner side of the straight groove 2 are respectively slidably connected with a sliding table 5. The table surface of the sliding table 5 is located above the table surface of the fixed table 1, and the table surfaces of the sliding tables 5 on both sides are flush. The straight grooves 2 are respectively provided with guide brackets 4 at positions close to both sides of the inner wall. The guide brackets 4 are provided with sliding grooves. Both sides of the sliding table 5 are respectively provided with pulleys, and the pulleys are embedded in the sliding grooves corresponding to t...

Embodiment 2

[0025] Pushing hydraulic cylinders are arranged along the edge positions on both sides of the fixed table 1, and the piston rod provided at the output end of the pushing hydraulic cylinder is connected to the connection of the two movable arms 8, and the entire triangular movement is realized by the pushing of the pushing hydraulic cylinder. The left and right movement of the arm 8 can be used to reduce the distance between the movable arms 8 on both sides of the fixed table 1 .

Embodiment 3

[0027] Remove the sliding table 5, fix one of the two movable arms 8 on one side of the fixed table 1, and the other movable arm 8 can rotate freely. The purpose of the angle between the movable arms 8.

[0028] A high-efficiency method of using the elastic triangular sand frame for forming flat plate parts, starting the two motors 10 inside the fixed table 1, and using the transmission of the gear 3 to realize the two sliding tables 5 in the same side straight groove 2. The purpose of moving in the opposite or opposite direction, so that in the process of moving the sliding table 5, it will further drive the position of the movable arm 8 to change. The included angle between the movable arms 8 becomes smaller, and when the two movable arms 8 move opposite to each other, the included angle between the movable arms 8 becomes larger. Finally, through the above design and use method, the angle of the sand frame can be precisely controlled, thereby Effectively responding to diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com