Adsorption platform of belt paving machine and control method of adsorption platform

A control method and technology for tape laying, applied in the field of automatic tape laying of composite materials, can solve problems such as tool damage, achieve the effect of realizing protection function and improving service life

Inactive Publication Date: 2022-06-21

常州新创航空科技有限公司

View PDF14 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the related technology, the automatic tape laying machine mostly has a gantry structure, and the composite material is laid on the adsorption platform as a strip layer, and the laid material tape is adsorbed and fixed on the adsorption platform through the action of negative pressure; Finally, it is cut by the cutting head, but during the cutting process, the steel plate with holes on the adsorption platform will cause damage to the cutter

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

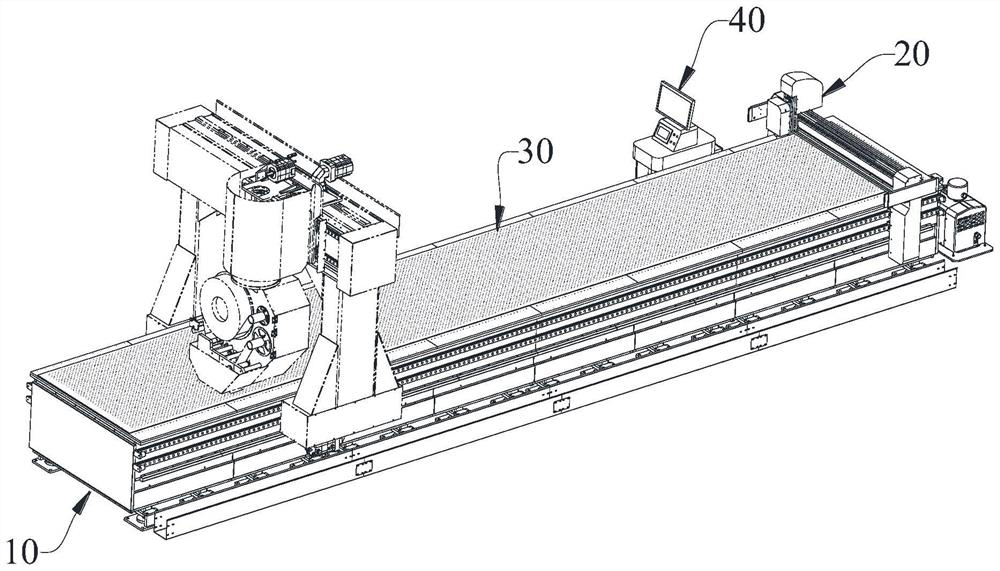

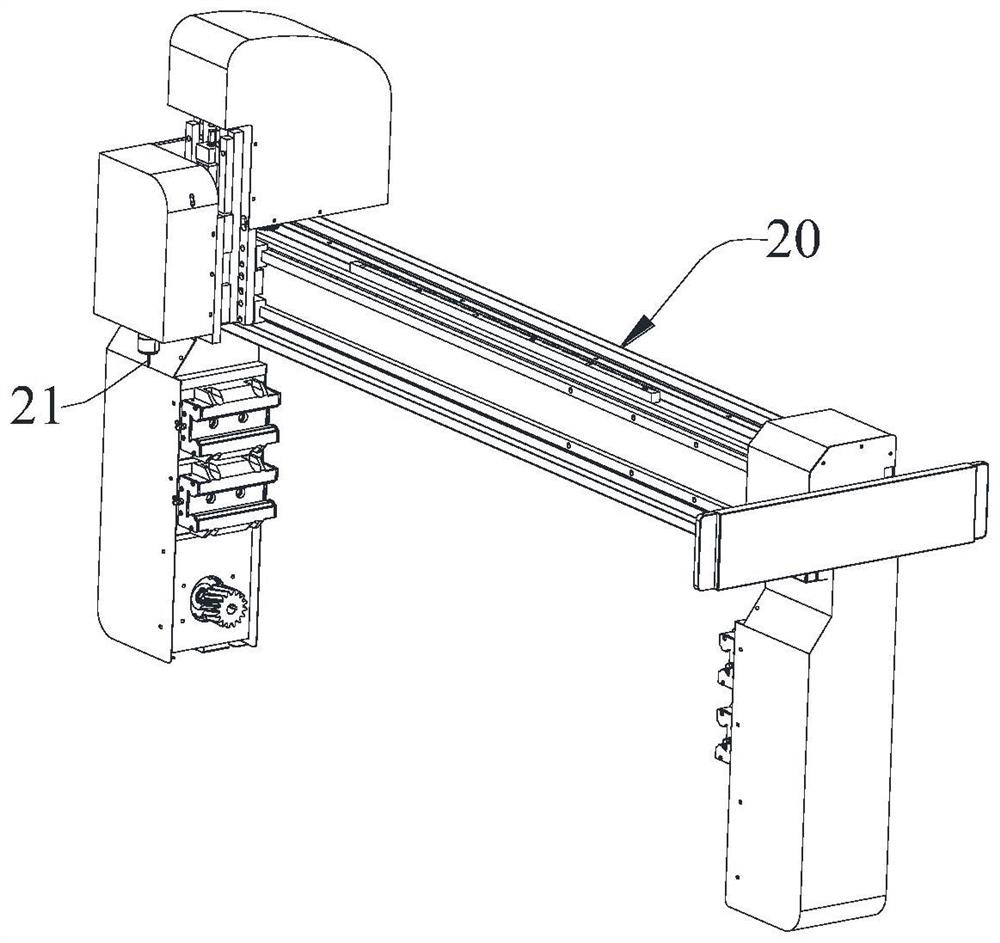

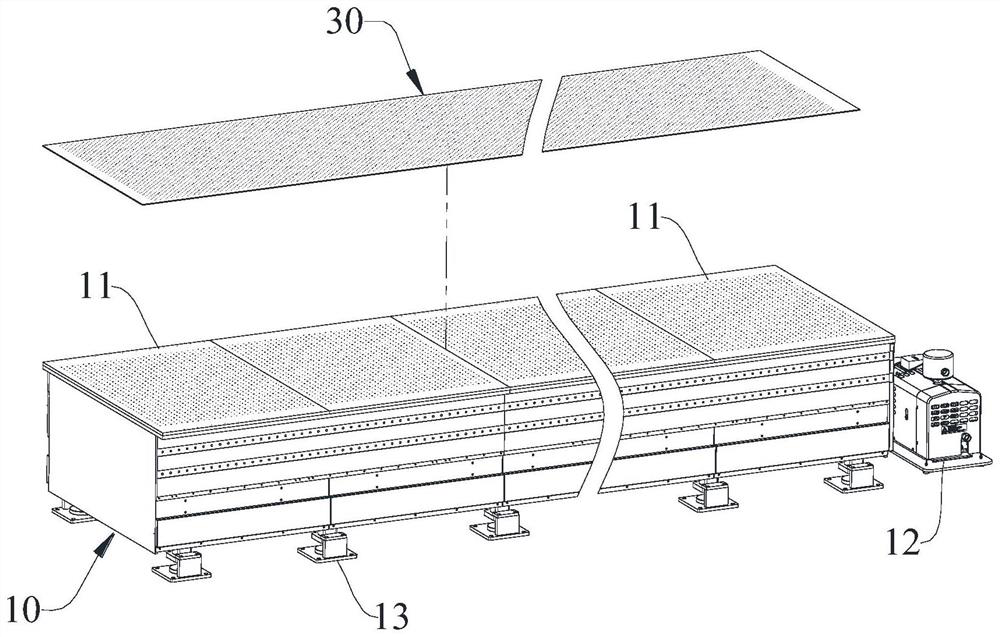

The invention relates to the technical field of automatic tape laying of composite materials, in particular to an adsorption platform of a tape laying machine and a control method thereof.The adsorption platform comprises a supporting table, the supporting table is of a cuboid frame structure, and the tape laying machine is movably arranged in the length direction of the supporting table; the cutting table stretches across the supporting table, the cutting table is movably arranged in the length direction of the supporting table, and a cutter movably arranged in the width direction of the supporting table is arranged on the cutting table; wherein a plurality of adsorption units are arranged on the upper surface of the supporting table and connected with a negative pressure generator through pipelines, and a breathable belt is laid on the upper surfaces of the adsorption units and used for protecting the cutter. By means of the breathable belt laid above the adsorption unit of the supporting table, ventilation can be achieved between the belt and the adsorption unit to achieve the adsorption and fixing effect on the laid belt, a cutter can be protected against damage, and the service life of the cutter is prolonged.

Description

technical field [0001] The invention relates to the technical field of automatic tape laying of composite materials, in particular to an adsorption platform of a tape laying machine and a control method thereof. Background technique [0002] When the size of composite material parts is large, the difficulty of manual laying increases correspondingly, the molding efficiency is low, and the product quality is difficult to guarantee. Therefore, the corresponding automatic tape laying technology (Automated Tape Laying, ATL) technology came into being; automatic tape laying The machine integrates the functions of prepreg tape cutting, positioning, laying and compacting, which not only greatly improves the production efficiency of composite components and reduces production costs, but also greatly Improve the reliability and stability of the quality of composite components; In the related technology, the automatic tape laying machine mostly has a gantry structure, and the compos...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B29C70/38B29C70/54

CPCB29C70/386B29C70/543B29C70/545

Inventor 谈源张俭唐海波丁文杰

Owner 常州新创航空科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com