Automatic measuring device for components

A technology for automatic measurement and components, which is applied in the direction of measuring devices, measuring device casings, and measuring electronics. It can solve problems such as the influence of measurement progress, pressure damage on the surface of circuit boards, and impact on measurement quality. It achieves simple and quick placement steps and improves measurement. Efficiency and quality, the effect of avoiding crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

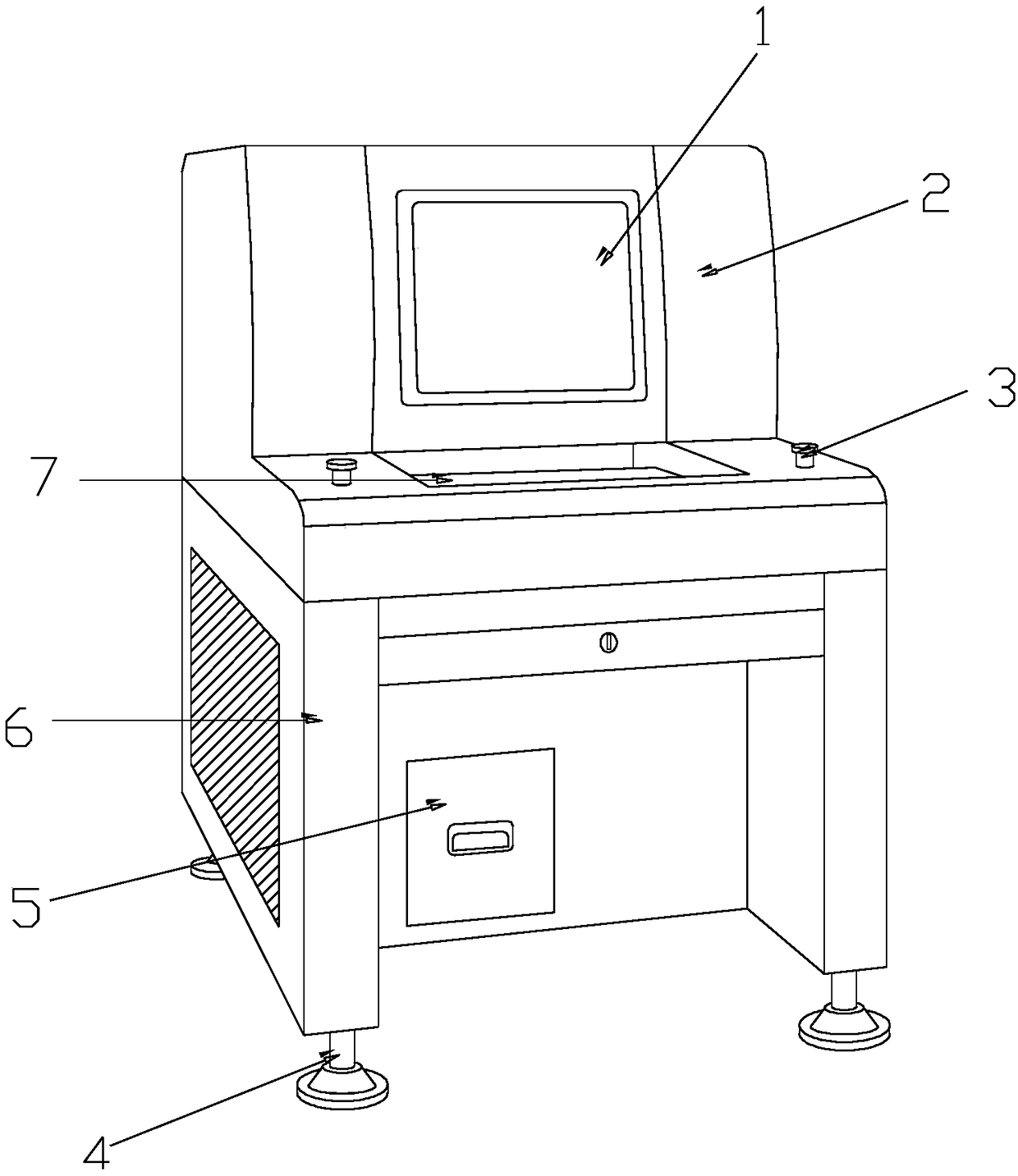

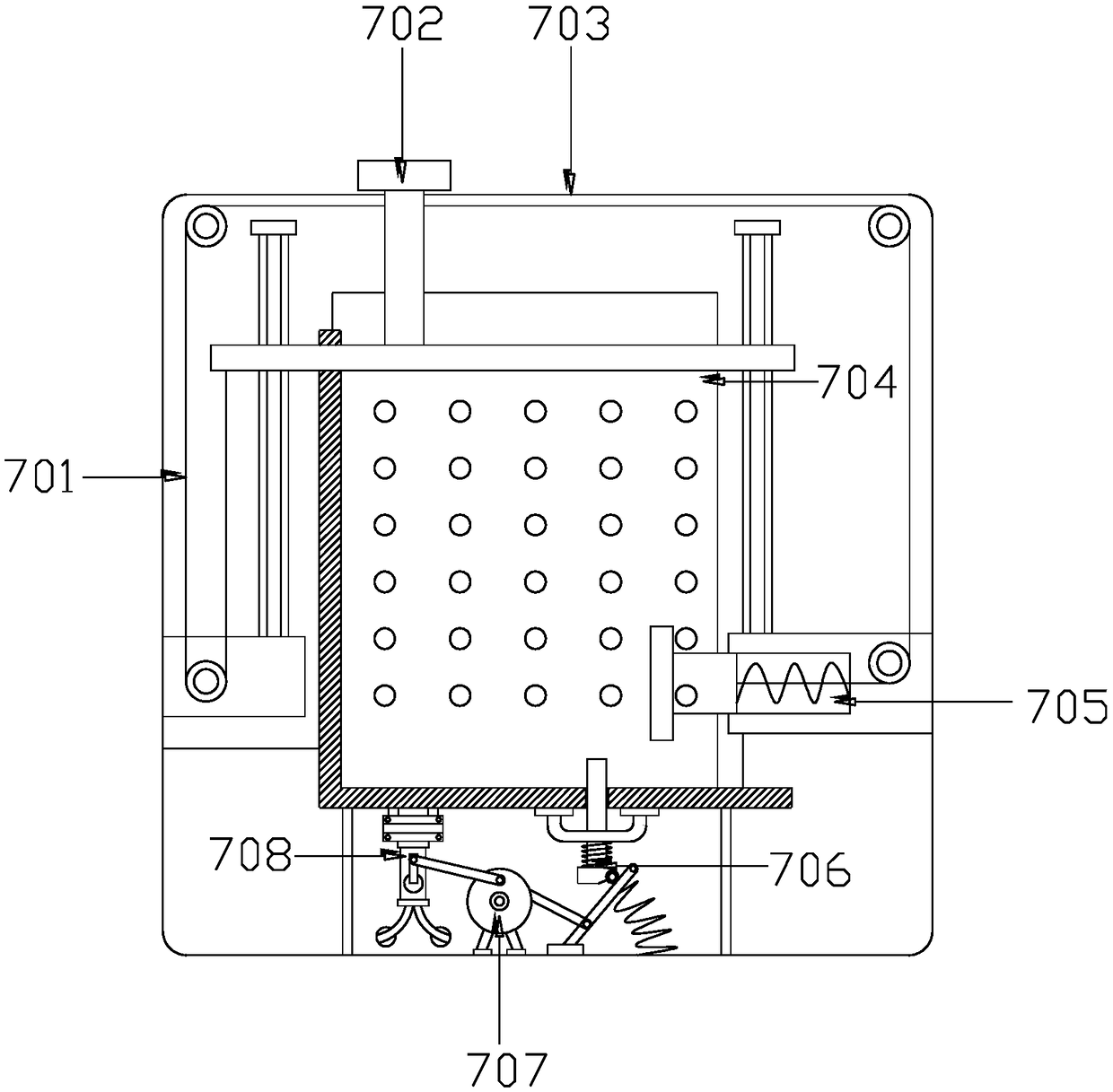

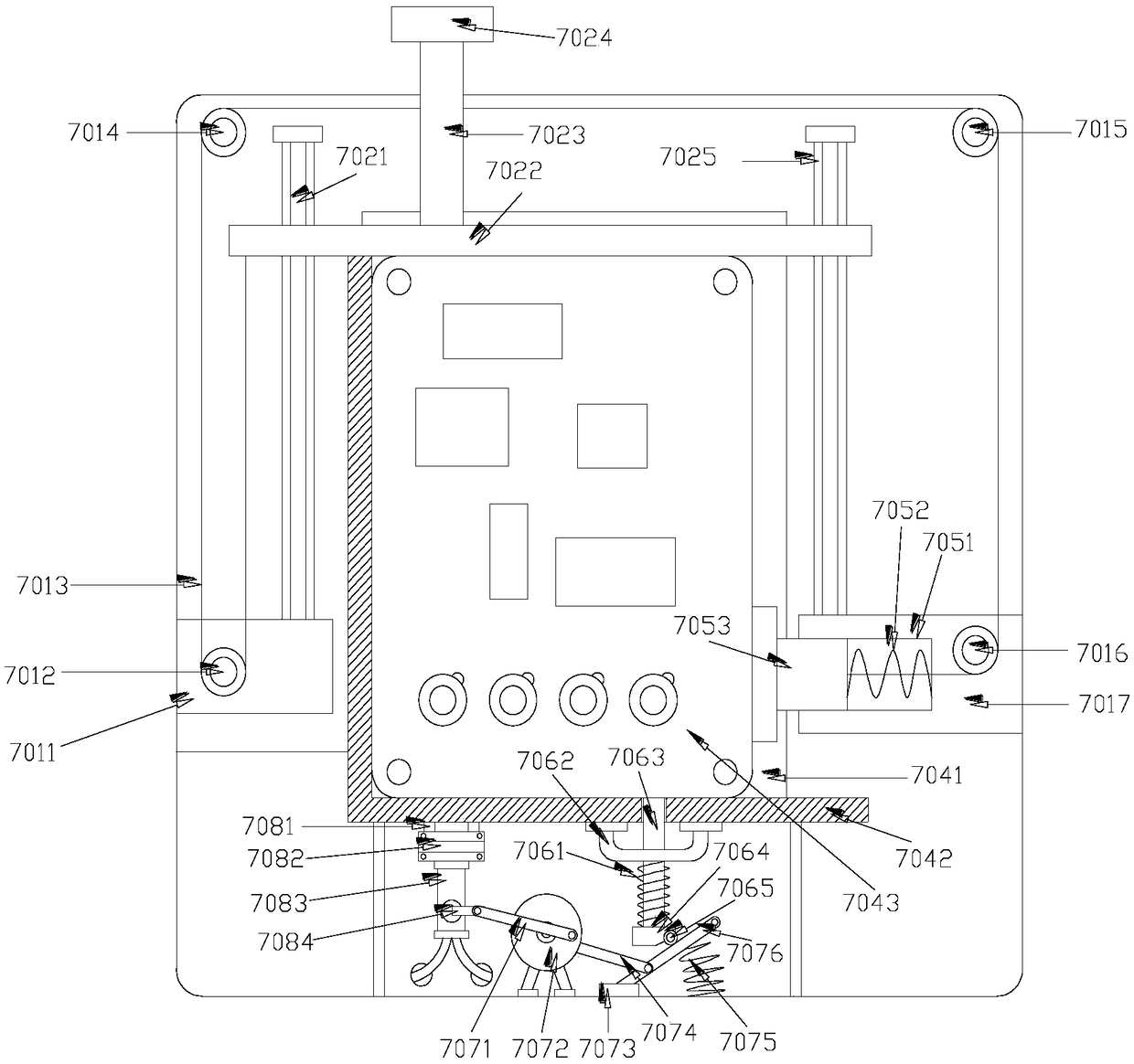

[0020] see Figure 1-Figure 3, the present invention provides an automatic measuring device for components, its structure includes a display 1, a measuring host 2, a start-stop button 3, a fixed foot 4, a locker 5, a host 6, a measuring table 7, and the fixed foot 4 are provided with four in total, and are installed on the four corners of the bottom of the host 6 by buckling. The middle part of the upper surface of the host 6 is provided with a measuring platform 7, the start-stop button 3 is installed on both ends of the top of the host 6 by embedding, the locker 5 is arranged inside the front end of the host 6, and the measuring platform 7 includes a linkage mechanism 701, reset device 702, housing 703, measurement and placement mechanism 704, positioning device 705, transmission mechanism 706, vacuum control mechanism 707, negative pressure mechanism 708, the measurement and placement mechanism 704 is set in the middle of the housing 703, and the right end of the bottom is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com