Cargo carrier for receiving in cargo area of aircraft with movable rolling elements

A technology of rolling elements and aircraft, applied in the direction of equipment for loading and unloading cargo, containers, large containers, etc., which can solve the problems of cargo sliding, large cross-section, and inability to pass through loading hatches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

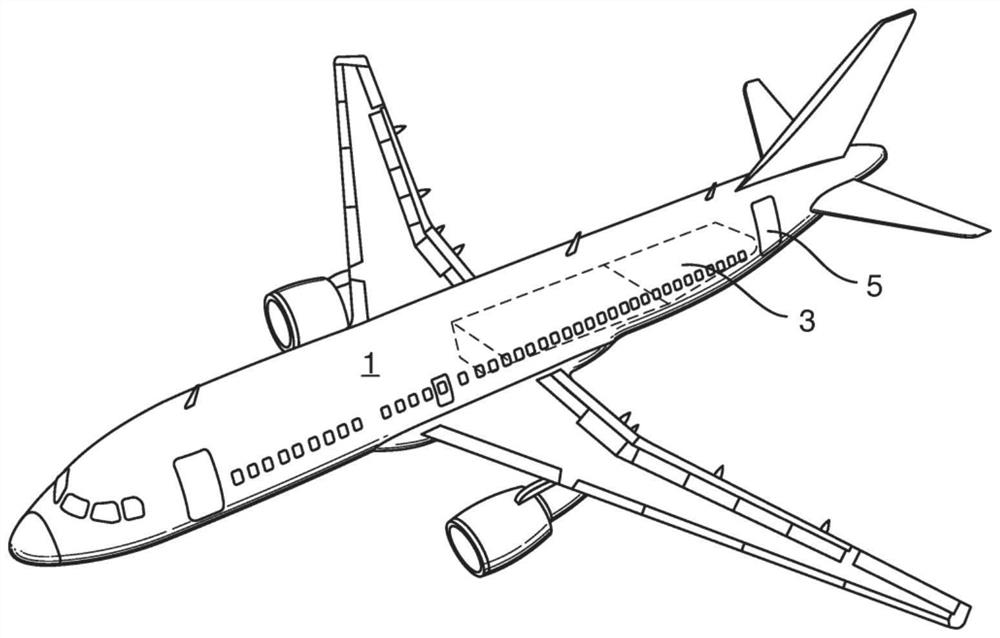

[0055] In the following, an embodiment of a cargo carrier will be described, which is provided for loading into figure 1 In the aircraft 1 shown in , wherein the cargo carrier can be loaded either into the original cargo hold 3 or into the passenger cabin through the passenger door 5 (if the passenger cabin is converted to accommodate the passenger seat by removing the passenger seat) goods). Here, the embodiment of the cargo carrier is designed in such a way that persons can move the cargo carrier in a simple manner not only in the original cargo compartment 3 but also in the passenger compartment.

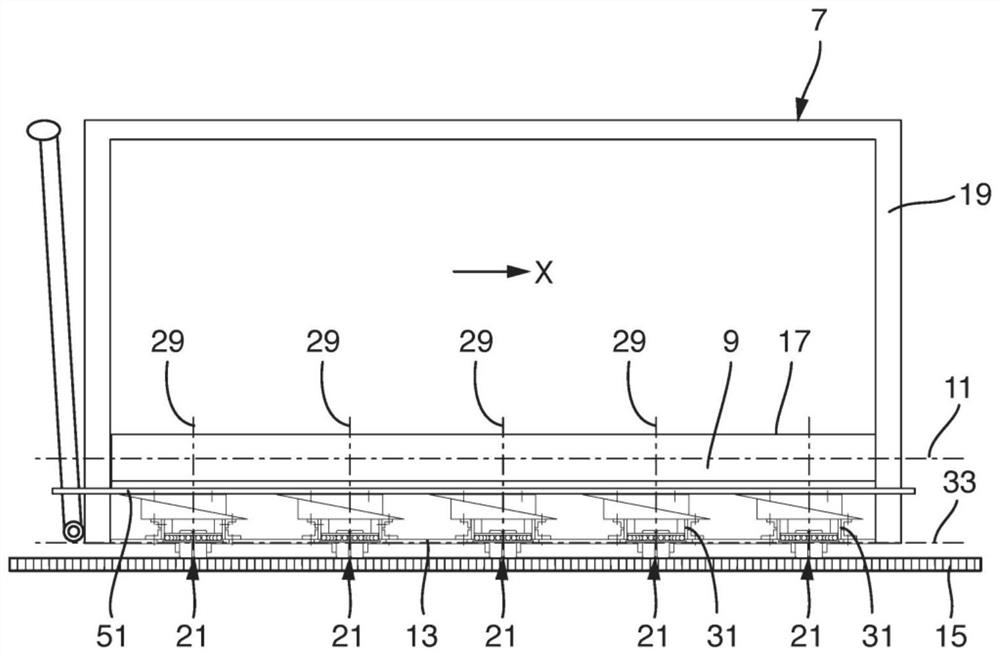

[0056] like figure 2 As can be seen, the first embodiment of the cargo carrier 7 according to the invention has a bottom element 9 which, in the first exemplary embodiment shown here, extends on the bottom element plane 11 and which has support sides 13 . , the support side is arranged and designed such that, in normal use of the cargo carrier 7 , the supporting side is direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com