Metal shade

A technology of metal masking and graphics area, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve problems such as uneven stress, achieve the effect of reducing length difference and avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

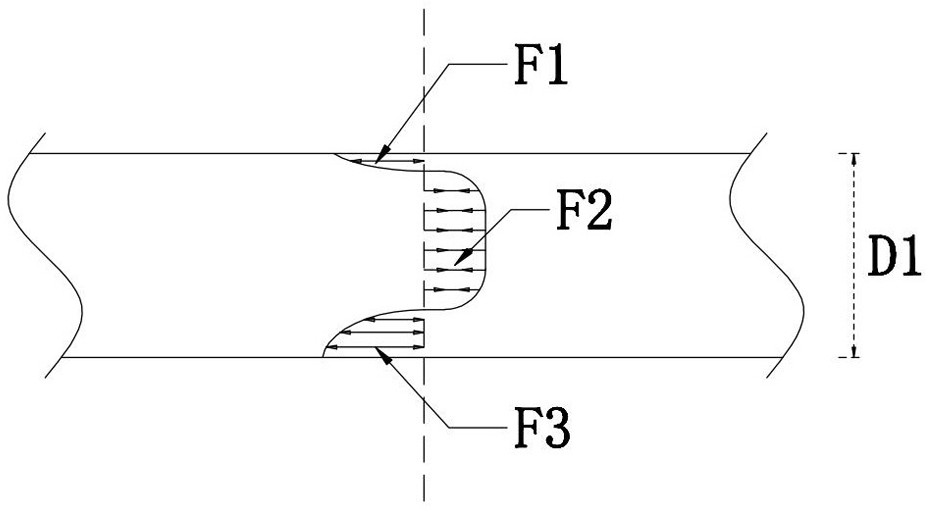

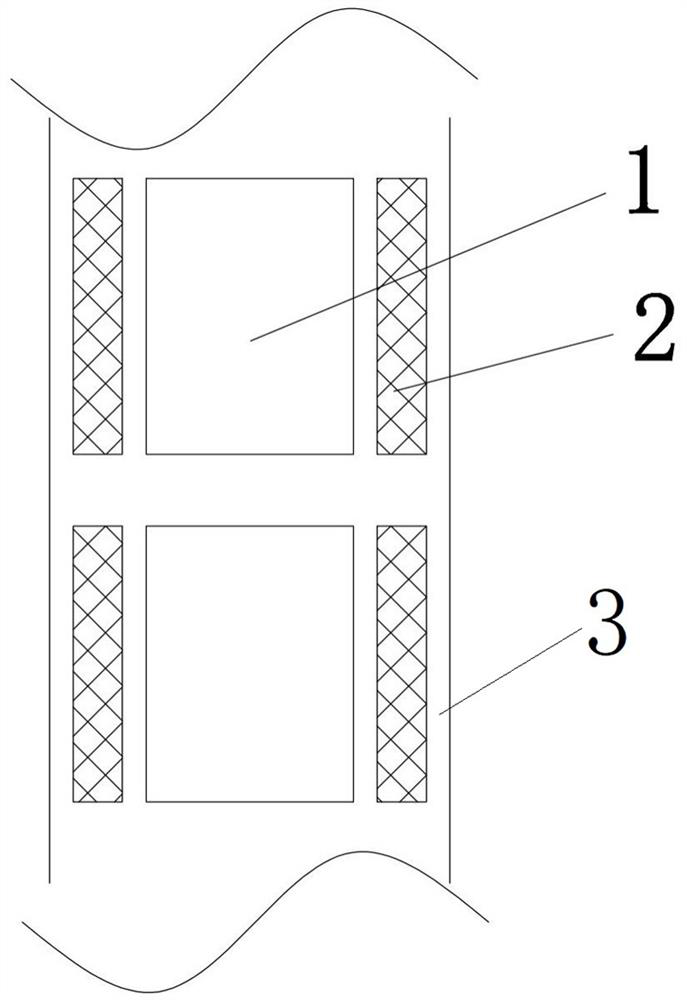

[0035] At the same time, the upper and lower surfaces are dislocated with concave grooves 21, which can avoid warping caused by stress release when the concave grooves 21 are set on one side, and through the structural design of staggered up and down, effectively avoid the situation of upper and lower perforations, and achieve simultaneous stress release on the upper and lower surfaces , and under the same area, the stress relief of the side pattern area 2 is nearly consistent with that of the main pattern area 1 .

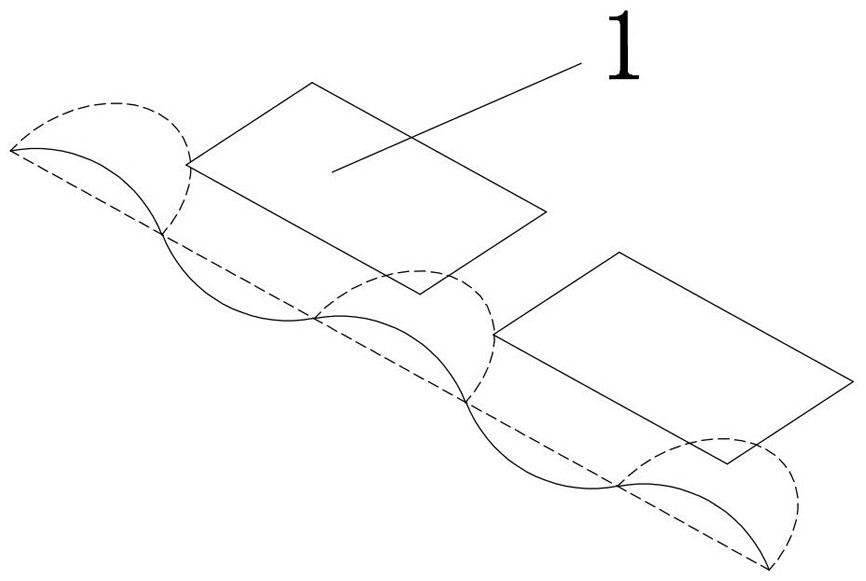

[0036] like Figure 4-Figure 6 As shown, the main pattern area 1 is provided with an upper etching hole 11 and a lower etching hole 12, and the surface size of the lower etching hole 12 is larger than that of the upper etching hole 11, and the size of the lower etching hole 12 is generally 1.2 to 2.2 times that of the upper etching hole 11 size, the size and unit area of the first concave groove 211 located on the upper surface of the edge pattern area 2 are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com