High-performance carbon fiber needling preform and preparation method thereof

A carbon fiber, high-performance technology, applied in the field of high-performance carbon fiber acupuncture preforms and their preparation, can solve the problems of limited densification, low product density, loss of fiber strength, etc., and achieve improved densification and uniform pore distribution. , the effect of reducing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

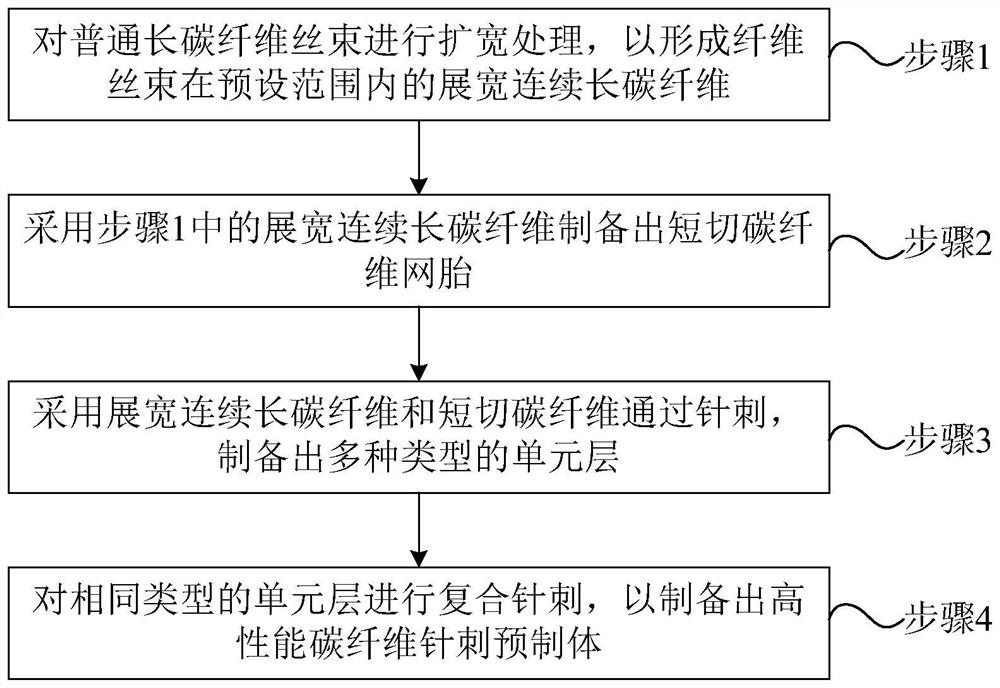

[0044] figure 1 It is a flow chart of the preparation method of the high-performance carbon fiber needle-punched preform provided by the embodiment of the present invention. like figure 1 As shown, the preparation method of the high-performance carbon fiber needle-punched preform provided by the embodiment of the present invention may include the following steps:

[0045] Step 1, widening the ordinary long carbon fiber tow to form a widened continuous long carbon fiber with the fiber tow within a preset range.

[0046] The implementation process of this step 1 may include:

[0047] 1) Pass the ordinary continuous long carbon fiber tow through the solvent at a certain speed (1-20) m / min (the solvent has the effect of dissolving the surface coating of the ordinary continuous long carbon fiber tow, that is, dissolves the resin on the surface of the fiber tow function) in the liquid tank, and ensure that the ordinary continuous long carbon fiber is completely immersed in the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com