High-rotating-speed detachable bearing for electric fan

An electric fan, high-speed technology, applied in the field of bearings for electric fans, can solve problems such as increasing bearing wear, and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

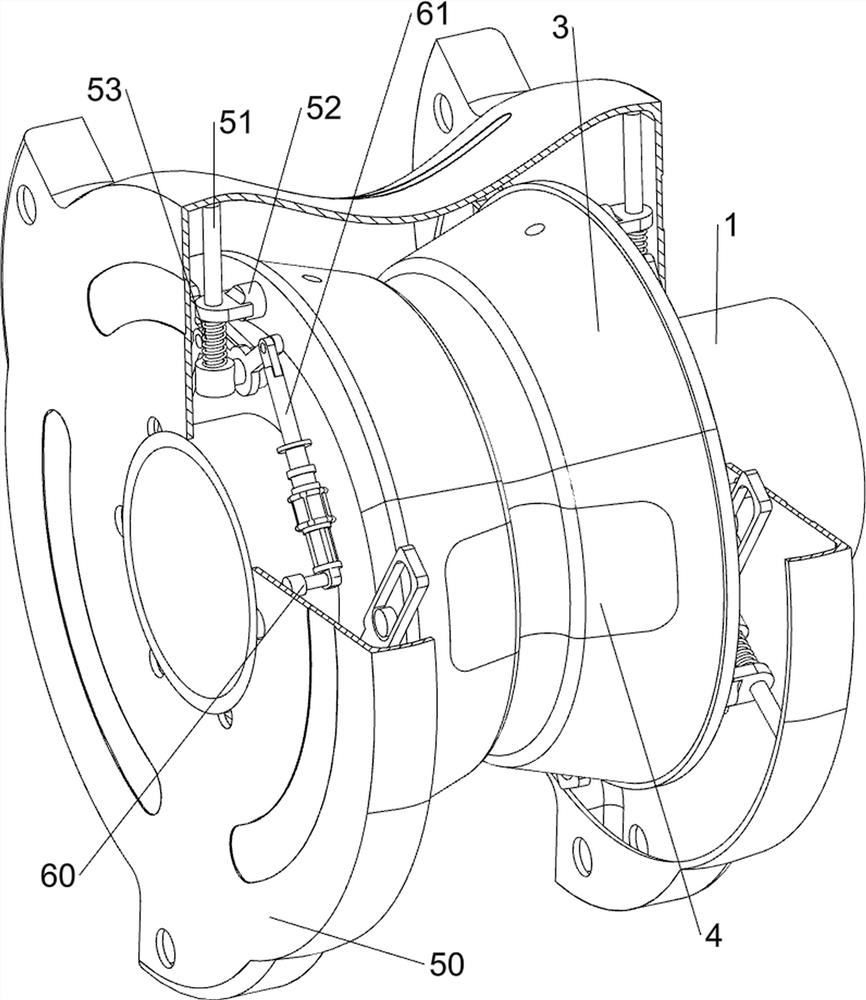

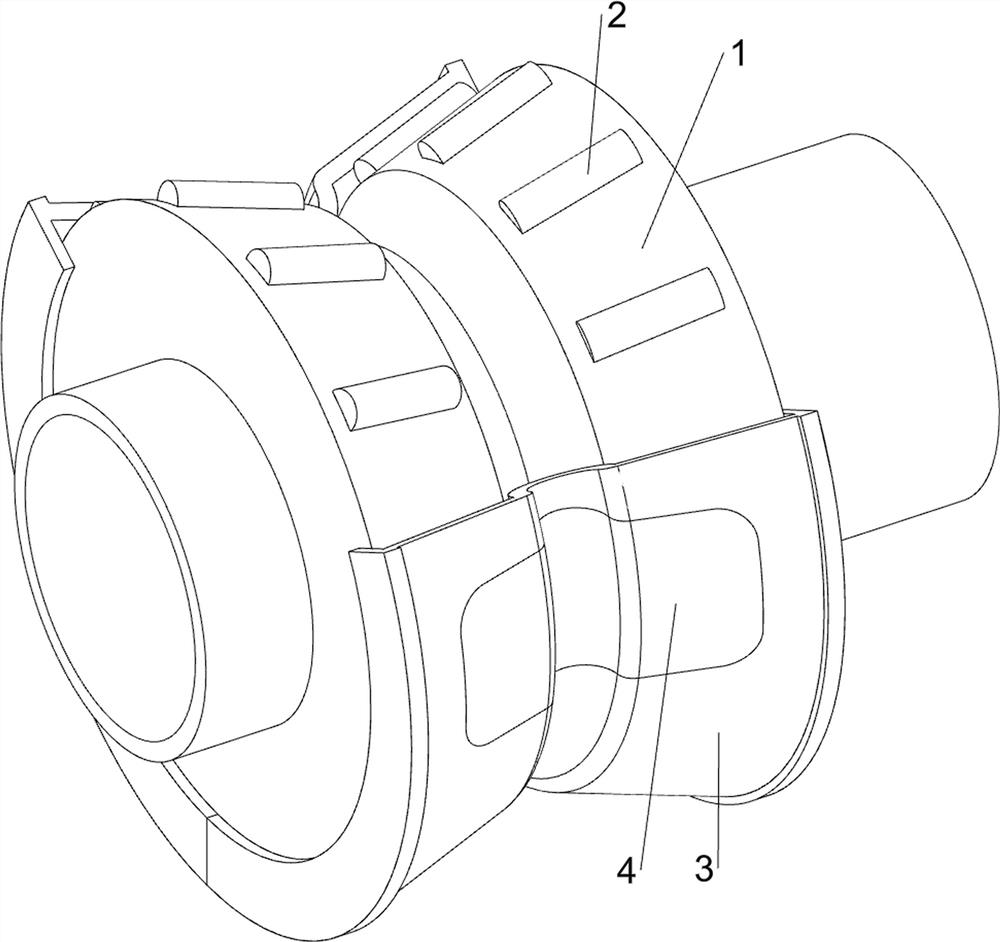

[0034] When using the device, the staff installs the device on the electric fan for use. When the fan blade rotates, the roller 1 rotates in the limit ring 3. Under the action of the ball 2, the distance between the roller 1 and the limit ring can be reduced. The frictional force between the positioning rings 3 enables the roller shaft 1 to rotate at a high speed. While the roller shaft 1 is rotating at a high speed, it will press the positioning ring 3 through the ball 2 to expand outwards. Under the action of the expansion mechanism 5, It can buffer the impact force of the limit ring 3 and reduce the wear of the limit ring 3 and the ball 2. At the same time, it can also keep the limit ring 3 in contact with the ball 2, thereby adjusting the pretightening force of the bearing. When individual balls 2 need to be disassembled, the staff opens the closing plate 4 for disassembly and replacement. When all the balls 2 need to be disassembled, the staff opens the limit ring 3 outwar...

Embodiment 2

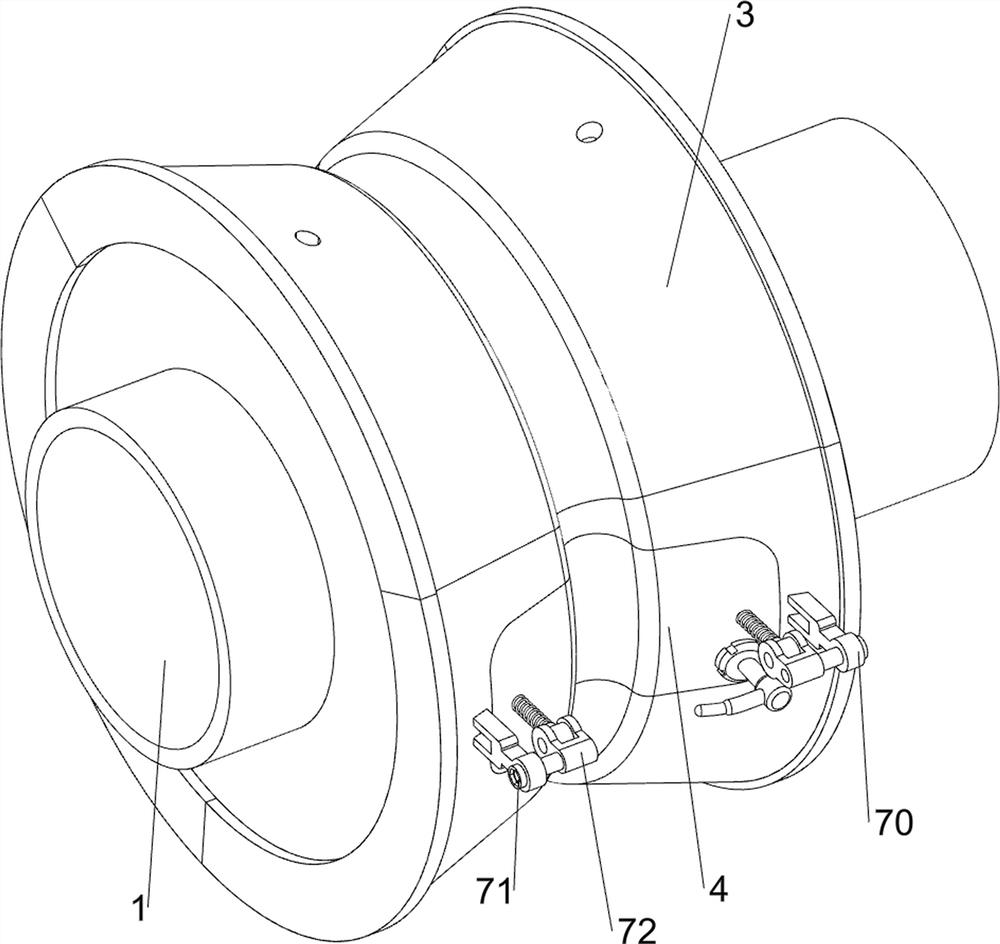

[0041] like figure 2 , Figure 9 and Figure 10 As shown, a lubricating mechanism 8 is also included. The lubricating mechanism 8 adds lubricating oil to the roller 1 and the ball 2. The lubricating mechanism 8 includes a feeding tube 80, a retaining cylinder 81 and a connecting spring 83. The left and right sides of the upper part of the protective shell 50 All are welded with a blanking tube 80, the lower part of the blanking tube 80 penetrates into the uppermost limit block, and three retaining tubes 81 are slidably arranged on the blanking tube 80, and a limiting groove 82 is opened on the retaining tube 81. Limiting slots 82 are all slidably connected with adjacent feeding pipes 80, and the uppermost limiting block moves upwards with retaining cylinder 81, and connecting spring 83 is connected between retaining cylinder 81 and the adjacent discharging pipe 80. The upper part of the pipe 80 is provided with six feeding troughs 84, and the top of the retaining cylinder 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com