Membrane water wall appearance detection device

A membrane-type water-cooled wall, shape detection technology, applied in measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of flanging, affecting production and use, wrinkles, etc., and achieve the effect of improving efficiency and high-efficiency detection

Active Publication Date: 2022-06-21

NANTONG GANGHUA BOILER CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Membrane water-cooled wall refers to the water-cooled wall composed of air-tight membrane-type water-cooled wall welded by flat steel and pipes. The membrane-type water-cooled wall is a tube-sheet structure. It is small, but it is easy to deform during the production process. At the same time, there are depressions or protrusions on the surface, which will affect the subsequent production and use, and the production steps of the membrane water wall are many. In the production process, rows of After the pipe bending machine bends the pipe, it is easier to deform the pipe, and there are defects such as wrinkles and flanging. However, in the current production process, manual inspection is generally used for inspection, which has low efficiency and poor accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

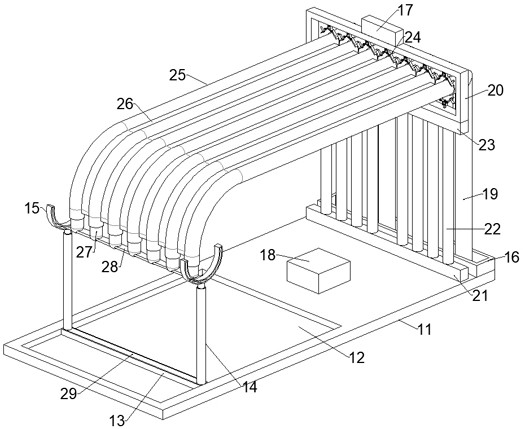

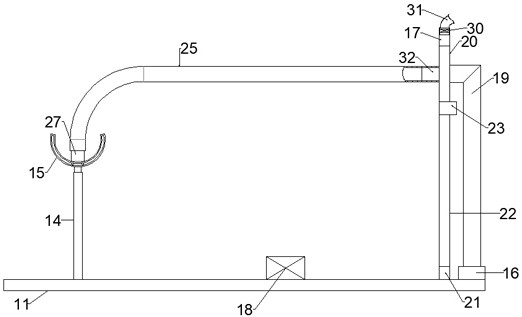

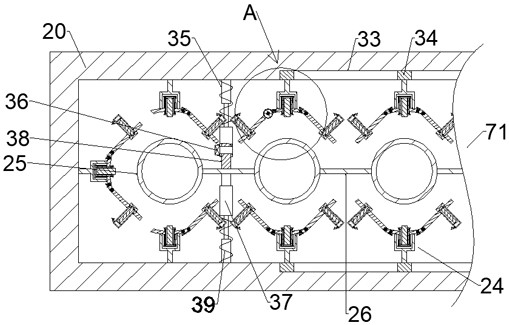

The membrane water-cooled wall appearance detection device comprises the detection mechanism arranged on one side of the sliding rod, the detection mechanism is used for detecting the flatness of a water-cooled wall tube and marking a defective surface for a user to find, the overall detection is accelerated, and a place with missed detection is avoided, so that subsequent improvement is facilitated, the product quality is guaranteed, and the production efficiency is improved. By arranging the detection mechanism, the membrane water wall can be detected after the pipe bending process is finished, the overall integrity of the membrane water wall after pipe bending is rapidly detected by utilizing the appearance characteristics of the camera and the membrane water wall, the influence caused by the diameter of a water wall pipe is avoided, the device is suitable for membrane water walls of various sizes, and the detection efficiency is improved. The membrane water-cooled wall can be detected more quickly and efficiently, and the subsequent production efficiency can be improved through adjustment performed after detection.

Description

technical field [0001] The invention relates to the related field of water-cooled wall detection, in particular to a membrane-type water-cooled wall shape detection device. Background technique [0002] Membrane water-cooled wall refers to the water-cooled wall composed of air-tight membrane-type water-cooled wall welded by flat steel and pipes. The membrane-type water-cooled wall is a tube-sheet structure. It is small, but it is easy to deform during the production process. At the same time, there are depressions or protrusions on the surface, which will affect the subsequent production and use, and the production steps of the membrane water wall are many. In the production process, rows of After the pipe bending machine bends the pipe, it is easier to deform the pipe, and there are defects such as wrinkles and flanging. However, in the current production process, manual inspection is generally used for inspection, which has low efficiency and poor accuracy. Contents of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N21/88G01N21/01

CPCG01N21/88G01N21/01

Inventor 顾本勇

Owner NANTONG GANGHUA BOILER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com