A multifunctional automatic trimming system for substrates used in solar panel processing

A solar panel, multi-functional technology, used in metal processing, liquid/vacuum measurement for liquid tightness, and measurement of fluid acceleration and deceleration rates. , to achieve the effect of tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

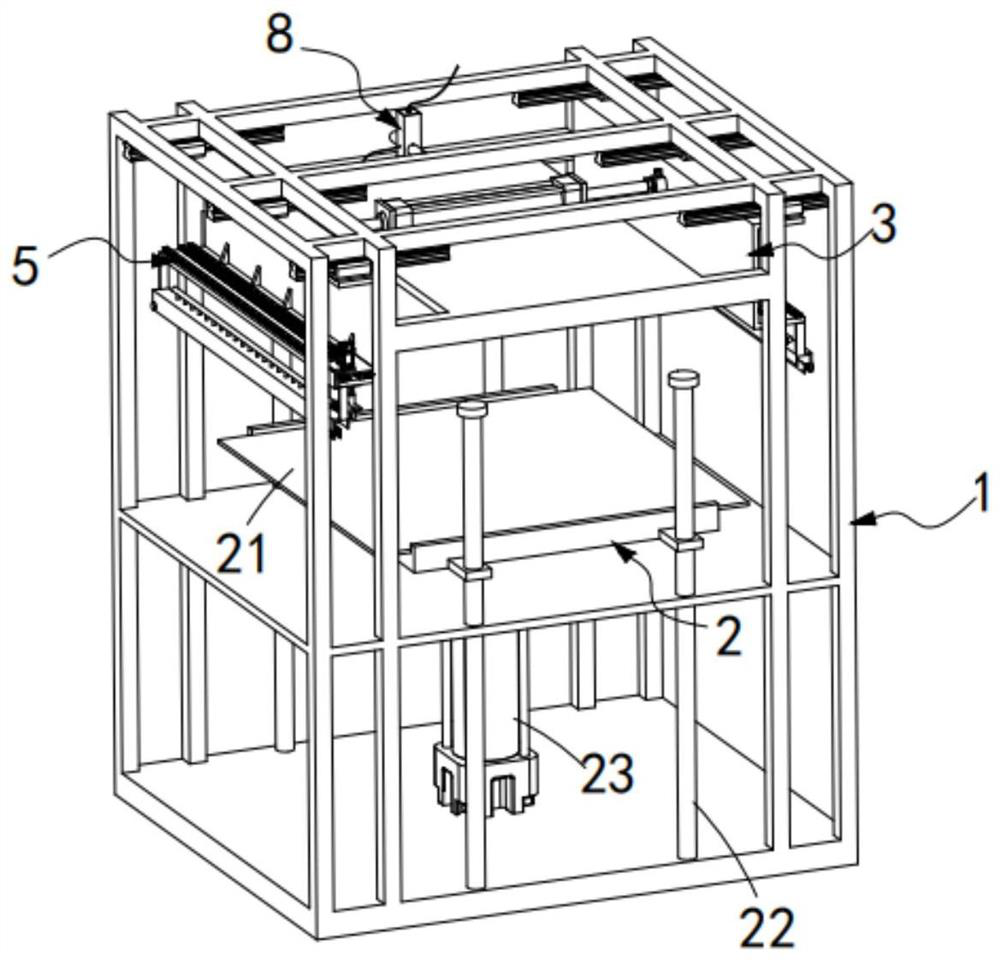

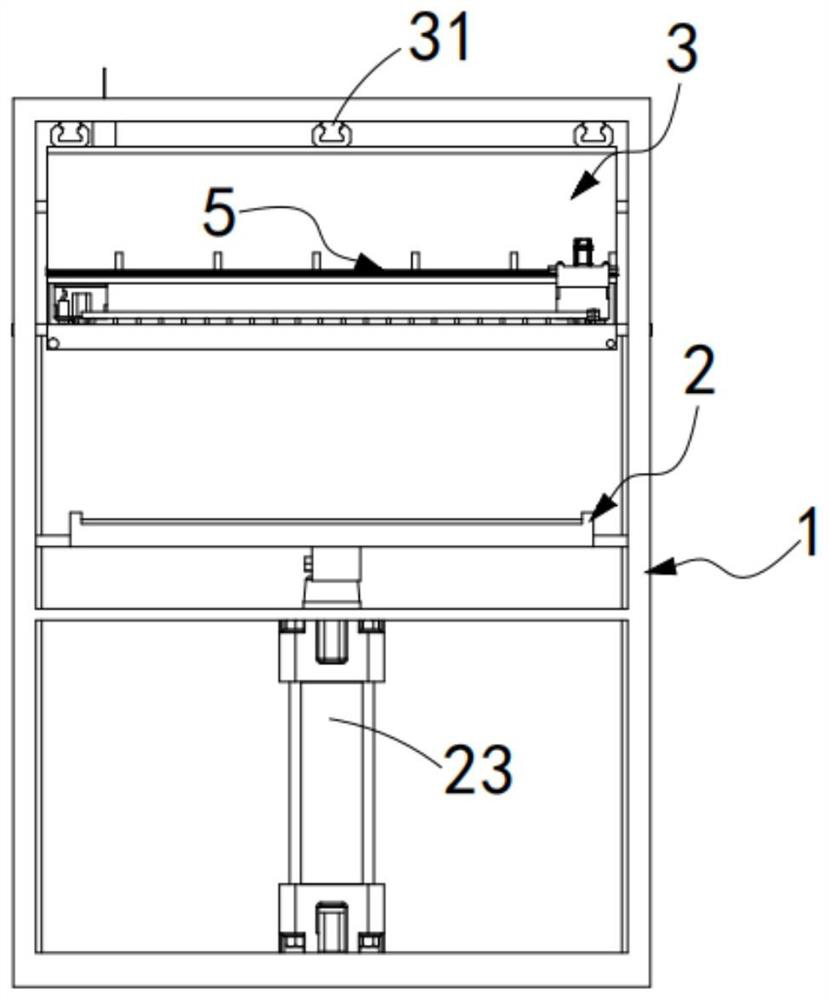

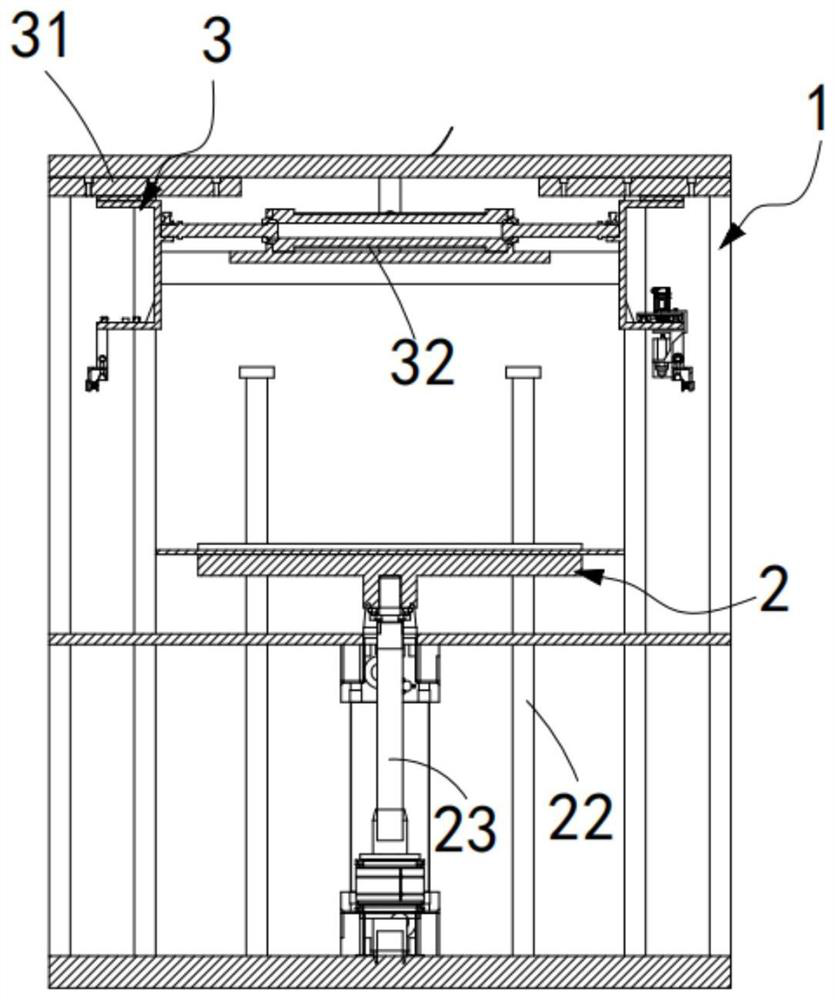

[0066] Such as Figure 1 to Figure 4 As shown, a multifunctional automatic trimming system for substrates for solar panel processing includes a frame 1 and a workbench 2 horizontally arranged on the frame 1. The workbench 2 is vertically lifted and set, and the workbench A photovoltaic cell substrate 21 is placed on the stage 2, which also includes:

[0067] A moving plate 3, the moving plate 3 is symmetrically arranged on the frame 1, is located above the workbench 2, and is horizontally slidably arranged;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com