Processing equipment for production of data storage server

A technology for processing equipment and data storage, applied in electrical digital data processing, digital data processing components, digital processing power distribution, etc., can solve the problems of inability to achieve automatic assembly, slow speed, etc., to achieve a high degree of automation and save labor. , The effect of saving manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

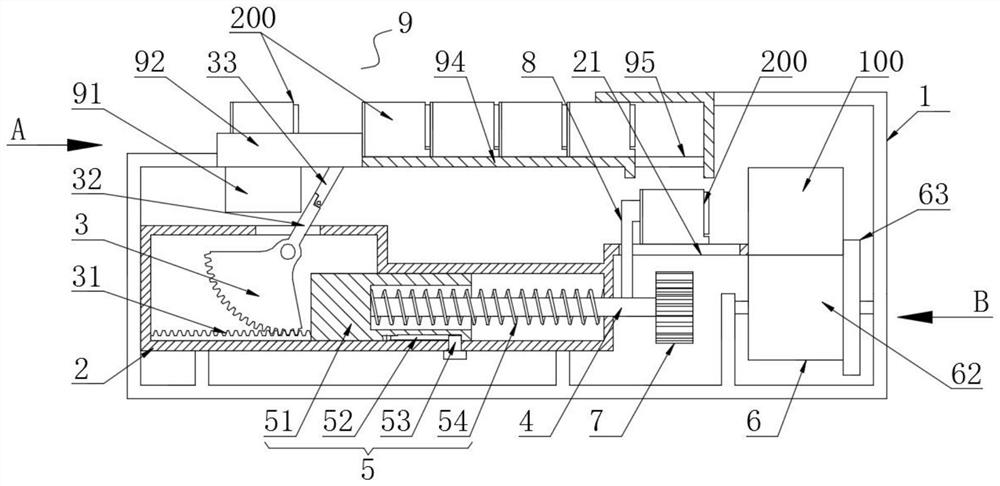

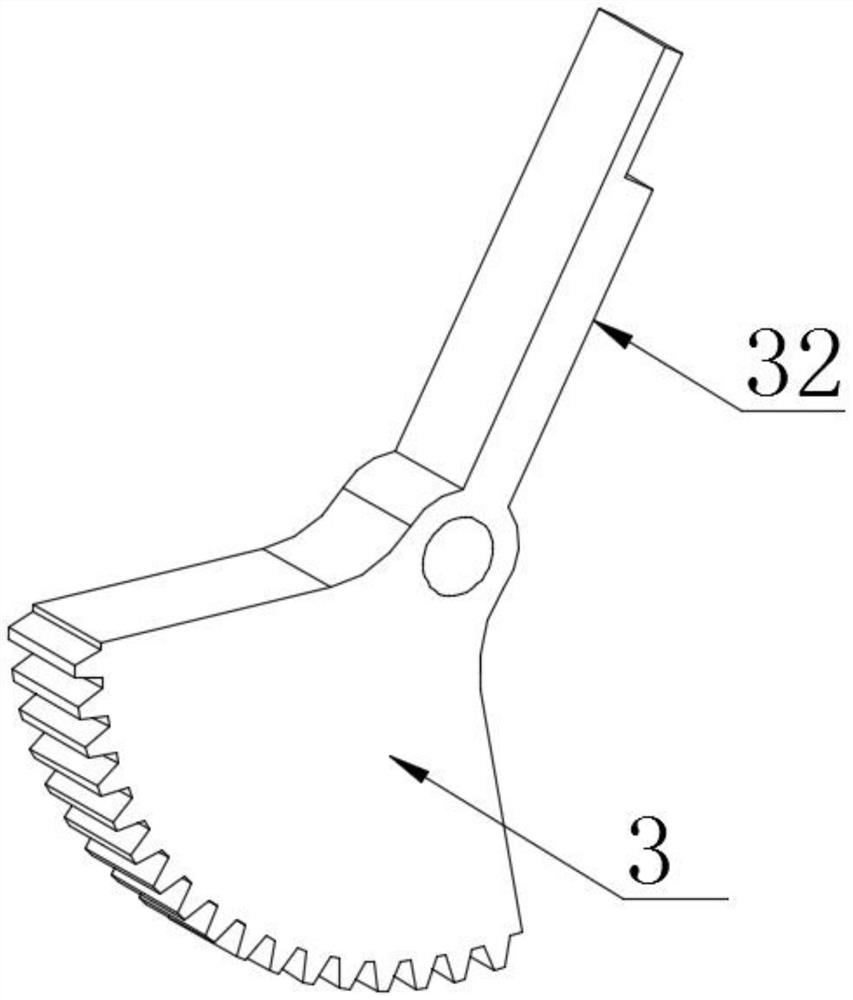

[0034] like Figure 1 to Figure 5 , Figure 7 and Figure 8 As shown, the processing equipment for data storage server production includes a main rack 1 and a sub rack 2 fixedly installed inside the main rack 1, one end of the sub rack 2 has a platform 21, and one end inside the sub rack 2 is rotatably connected with a drive Component 3, the other end of the sub-frame 2 is provided with a straight rod 4, and the driving component 3 is driven by a power component, such as a motor, an air cylinder, and the like.

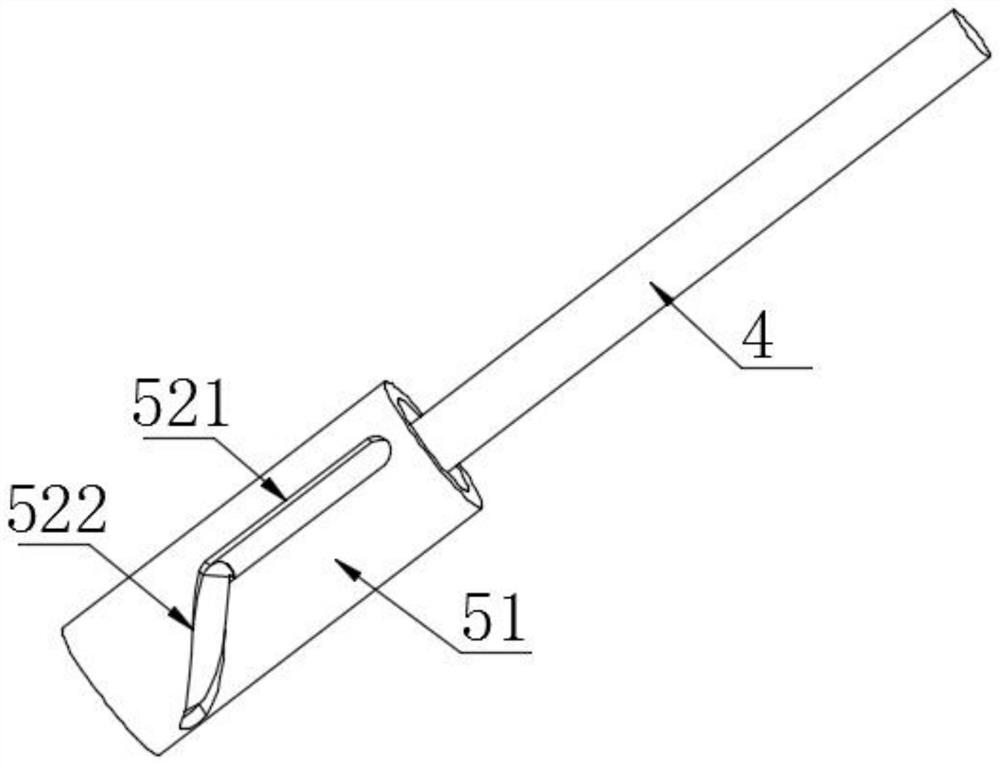

[0035] A guide assembly 5 is also provided between the driving component 3 and the straight rod 4. Specifically, the guide assembly 5 includes a movable cylinder 51 movably installed inside the sub-frame 2, the straight rod 4 is fixedly connected with the movable cylinder 51, and the movable cylinder 51 A guide groove 52 is provided on the outer surface of the guide groove 52. The guide groove 52 includes a straight groove 521 and a spiral groove 522 which are connect...

Embodiment 2

[0050] like figure 1 and Figure 8 As shown, on the basis of the first embodiment, the equipment is also provided with a feeding assembly 9, the feeding assembly 9 includes a conveying part 91 and a stage 92 on one side of the conveying part 91, and the conveying part 91 can be carried out by a conveyor belt. delivery. A bottom groove 93 is formed at the bottom of the stage 92 away from the conveying member 91. The upper end of the driving member 3 is fixedly connected with a swing rod 32, and the upper end of the swing rod 32 is connected to a push rod 33 through a torsion spring. The groove 93 protrudes above the stage 92 . The feeding assembly 9 also includes a conveying plate 94 fixedly connected with one end of the object platform 92 , and a blanking port 95 is opened at one end of the conveying plate 94 located above the platform 21 .

[0051] working principle:

[0052] Use the conveying member 91 to convey the hard disk extraction box 200 to the stage 92. During th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap