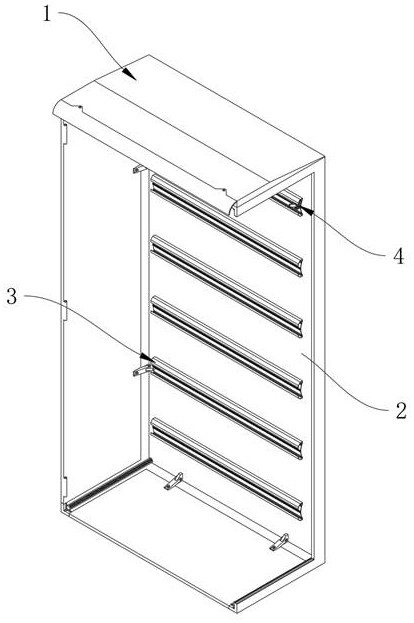

Power distribution cabinet element installation wiring structure

A wiring structure and power distribution cabinet technology, applied to electrical components, substation/switch layout details, busbar/line layout, etc., can solve the problems of low installation efficiency, complicated operation, and inability to conveniently realize line layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

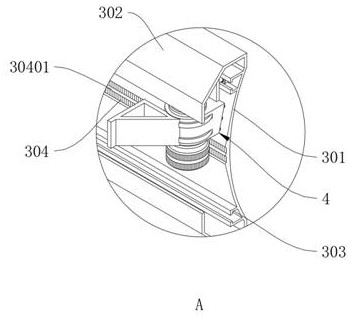

[0029] The periphery of the swivel 603 is provided with a plurality of vertical slots in a circular array, and the slots are equipped with line cards 605 for limiting lines.

[0030] refer to Figure 5 and Figure 8 As shown, the reciprocating direction of the wire management mechanism assembly 6 is consistent with the axial direction of the guide shaft 411, the end of the guide shaft 411 is threaded, and is fixed in the transmission cavity by the screw thread at the end, the guide shaft 411 The end far away from the thread is engaged and limited by the connecting ear 40701 provided on the cover 407 . The guide shaft 411 is far away from the threaded end and has a limiting disc, and the rod body of the guide shaft 411 facing the threaded end is covered with a return spring 41101. The other end of the return spring 41101 abuts against the sliding sleeve 602. When the cam assembly 5 rotates , because of its eccentric structure, push the wire management mechanism assembly 6 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com