Machining method and structure of composite material wing cover

A composite material and processing method technology, applied in the field of aircraft skin, can solve the problems of difficult to apply wing skin structure of large aircraft, limit molding quality and production efficiency, wing skin fiber delamination damage, etc., and achieve optimization. Mechanical properties, improve molding quality and production efficiency, and ensure the effect of overall force transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

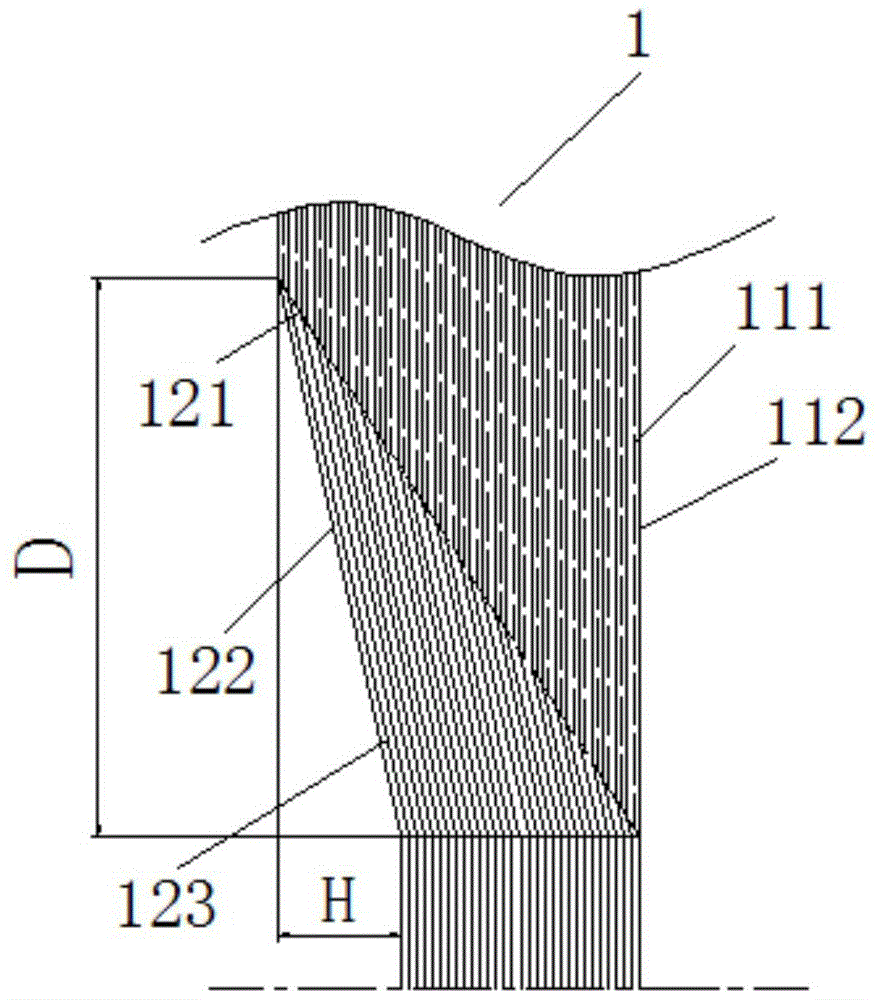

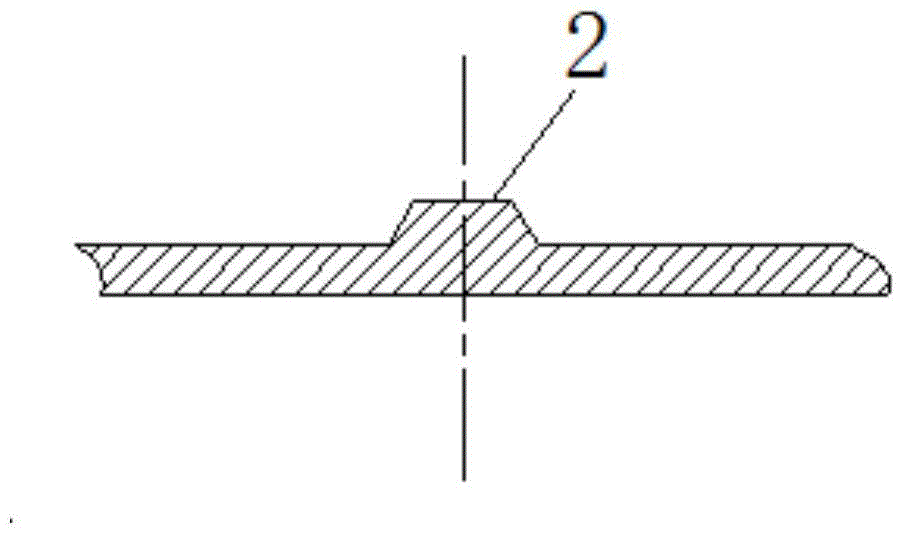

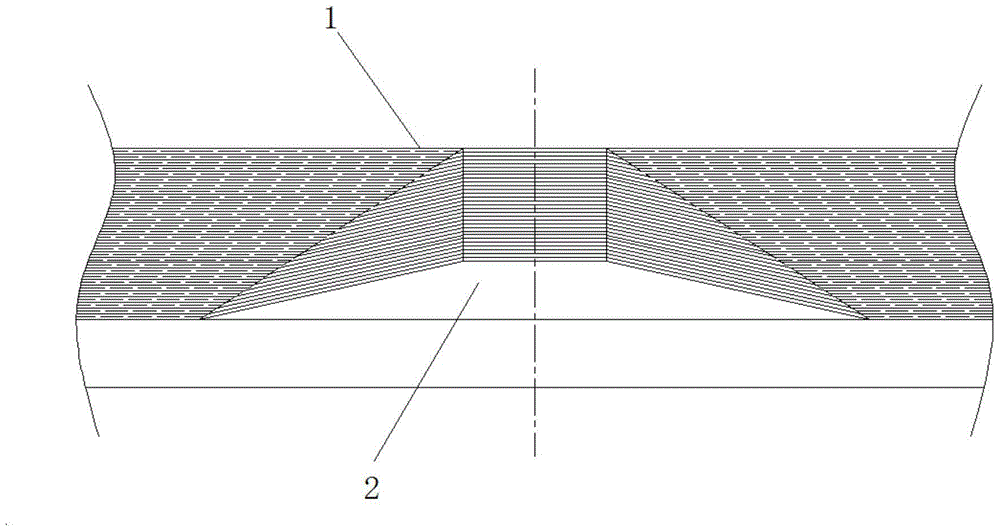

[0030] Such as Figure 1 to Figure 5 Shown, a kind of processing method of wing skin of composite material, described wing skin 1 comprises multi-layer lamination, described wing skin 1 is provided with inspection port 13, and the edge of described inspection port 13 is provided with There is a slope matched with the edge of the maintenance cover, and the laying includes manual laying 111 and automatic laying laid in staggered layers, and the processing method includes the following steps:

[0031] A. Cut each layer of hand-laid layer 111 so that a prefabricated hole 1111 with the same shape as the inspection port 13 is formed on the hand-laid layer 111. The size of the prefabricated hole 1111 on the hand-laid layer 111 changes layer by layer to form the said slope;

[0032] B. On one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com