Direct-current excitation magnetic separator capable of adjusting magnetism and speed

A DC excitation and magnetic separator technology, applied in the field of magnetic separators, can solve the problems of high cost, inability to adjust the magnetic position and speed, and need to be magnetized, and achieves the effect of reducing the cost and avoiding non-magnetic weakening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

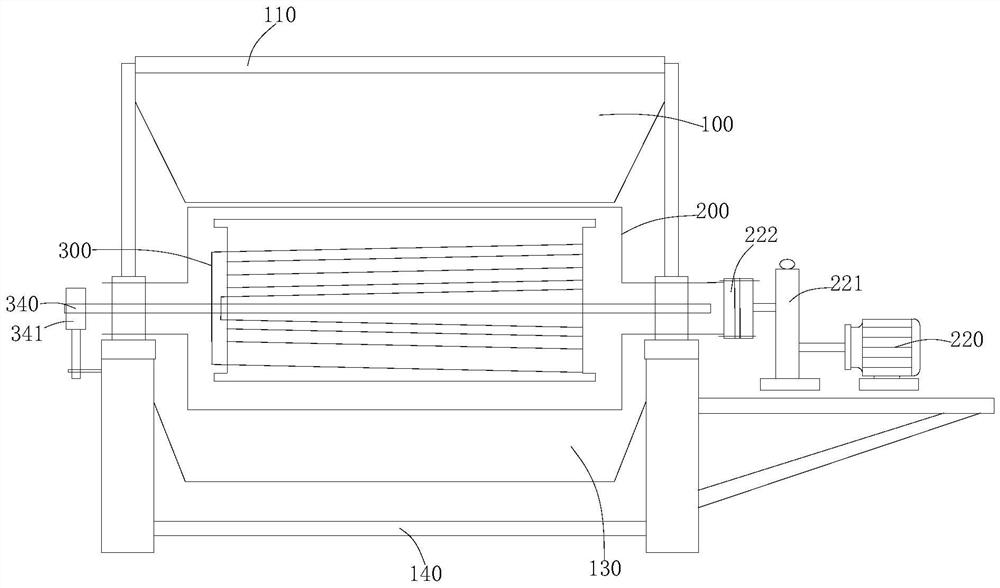

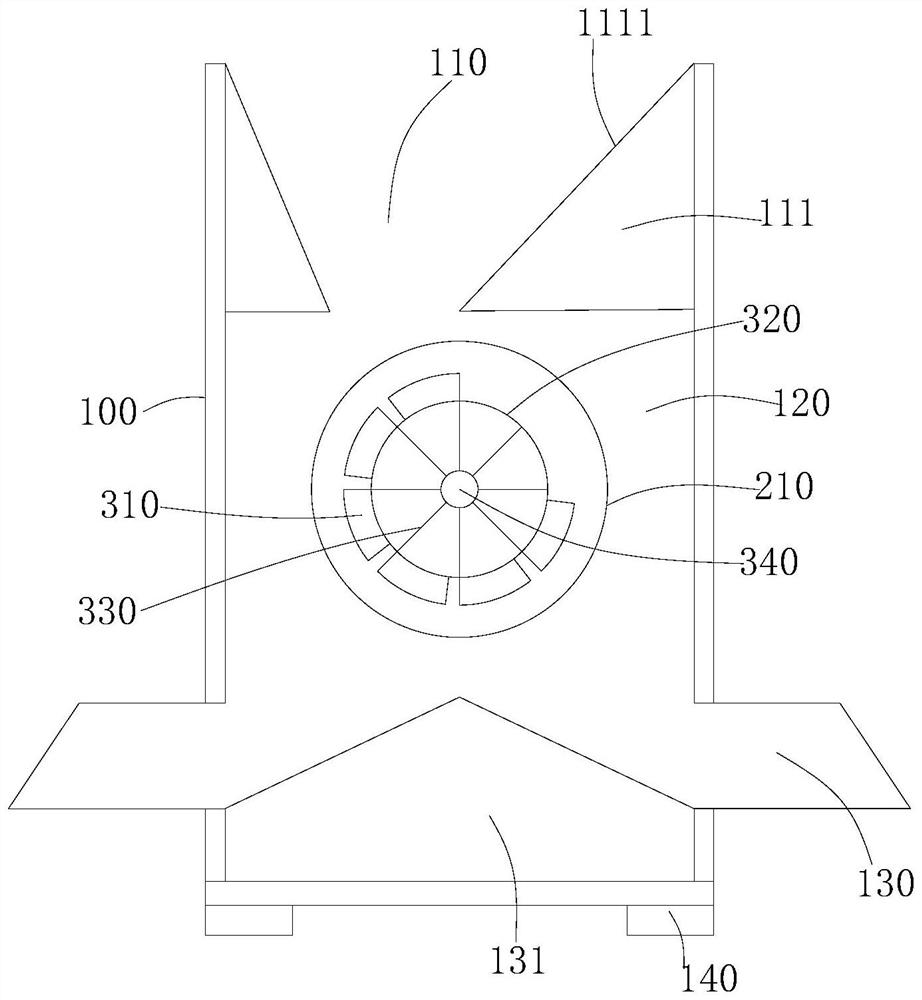

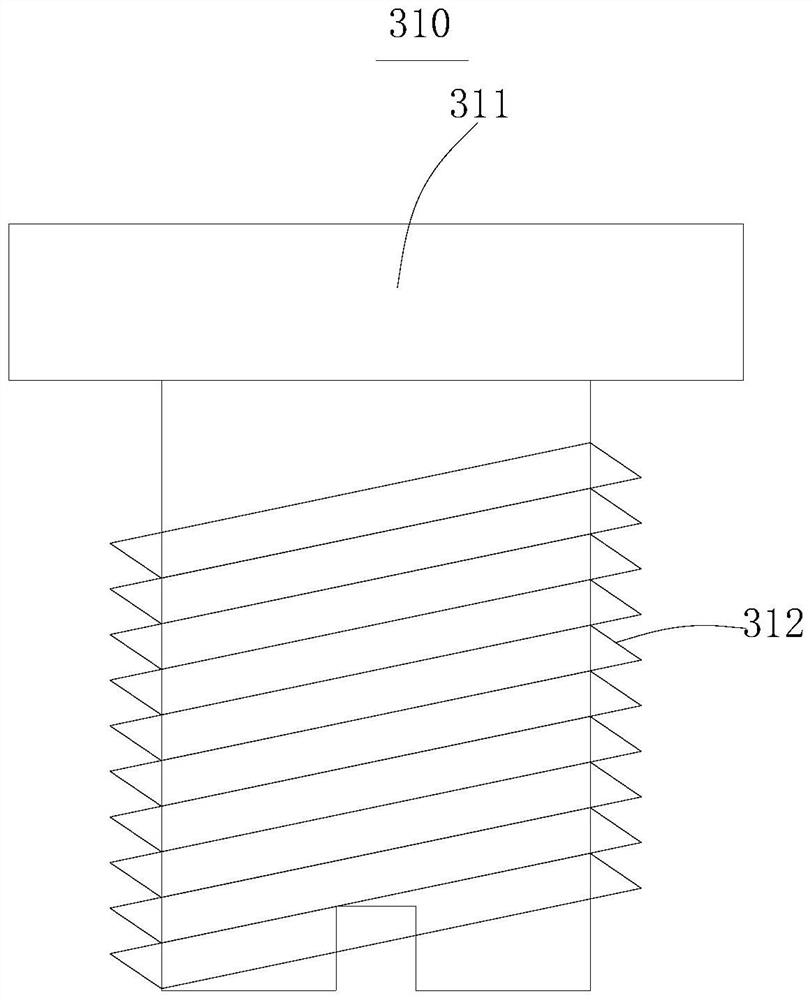

[0037] see figure 1 , the present invention provides a technical solution: a DC excitation adjustable magnetic speed-regulating magnetic separator, comprising a material distribution box 100 , a rotating assembly 200 and an excitation assembly 300 .

[0038] Among them, see figure 1 , the rotating component 200 and the excitation component 300 are installed on the material distribution box 100, the material distribution box 100 is used for receiving materials, and the rotating component 200 cooperates with the excitation component 300 to separate the magnetically conductive material and the non-magnetically conductive material in the material.

[0039] see figure 1 and figure 2, the material distribution box 100 has a feeding port 110, a material distribution cavity 120 and two discharge ports 130 that communicate with each other, wherein, the feeding port 110 has a guide block 111, specifically, the guide block 111 has a guide slope 1111, the guide slope The 1111 can guid...

no. 2 example

[0045] Based on the adjusting member 341 provided in the first embodiment of the present application, the second embodiment of the present application provides another adjusting member 341 . The adjusting member 341 in the first embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0046] The second embodiment of the present application will be further described below with reference to the accompanying drawings and embodiments.

[0047] see figure 1 and Figure 7 Specifically, the adjustment bolt seat 3413 is directly fixed on the support frame 140, and the adjustment rod 3411 is hinged on the support frame 140 through the rotating shaft. When the magnetic position needs to be adjusted, the bolt on the adjustment bolt seat 3413 is rotated, and the bolt is pressed against the One end of the adjustment rod 3411 rotates around its axis of rotation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com