Transmission mechanism of double-layer vibrating screen classifier for tobacco shred production line

A double-layer vibrating screen and transmission mechanism technology, which is applied in the fields of filtering, solid separation, tobacco preparation, etc., can solve the problems of large force on the main shaft of the eccentric transmission assembly, easy aging deformation of pull tabs, wear and tear failure, etc., and achieve high promotion Application value, reduction of failure rate and maintenance cost, effect of failure rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The technical solutions of the present application will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

[0035] The technical solution of the present application is an improvement on the existing double-layer vibrating screen, and this improvement does not involve the aspect of electric control. Therefore, the electric control of the improved double-layer vibrating screen has not changed.

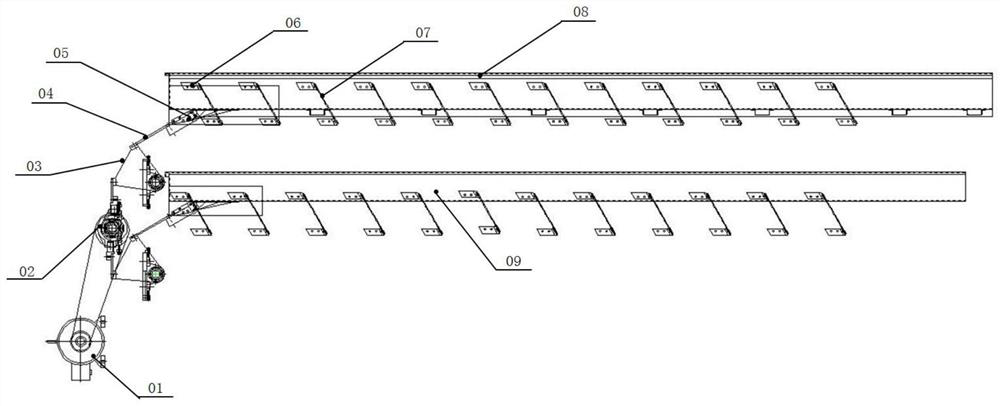

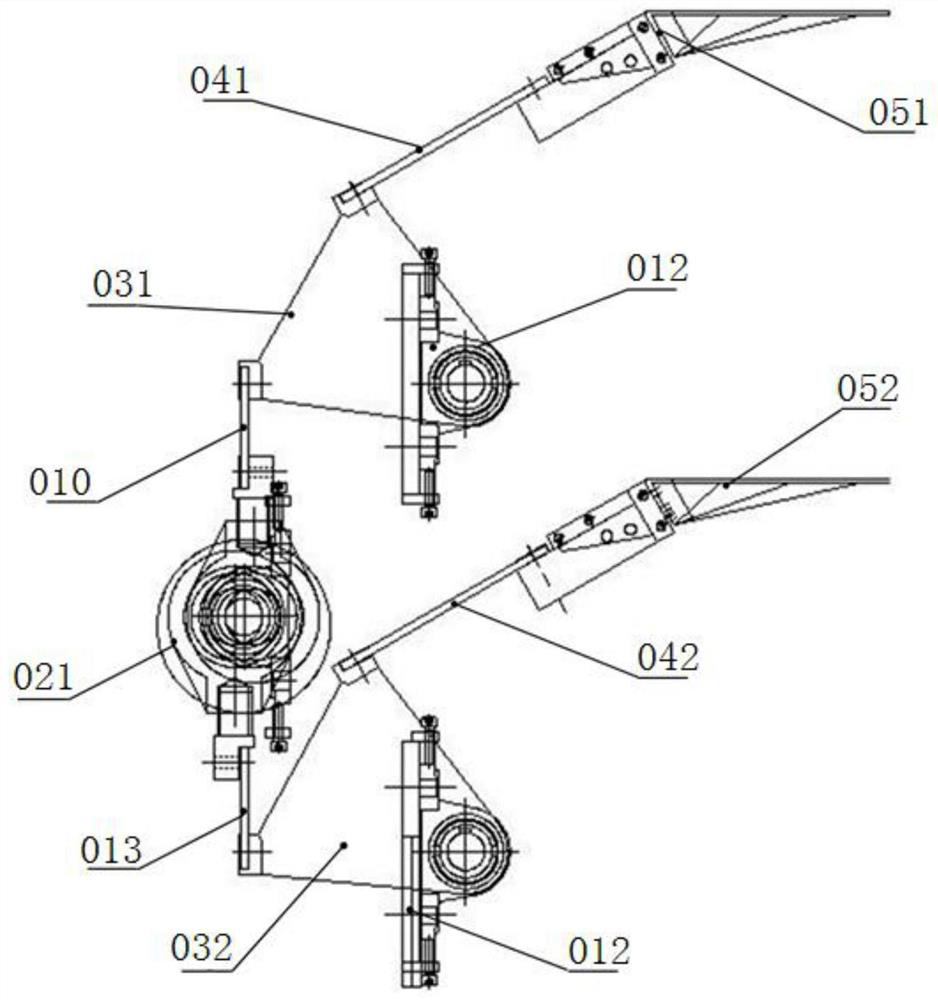

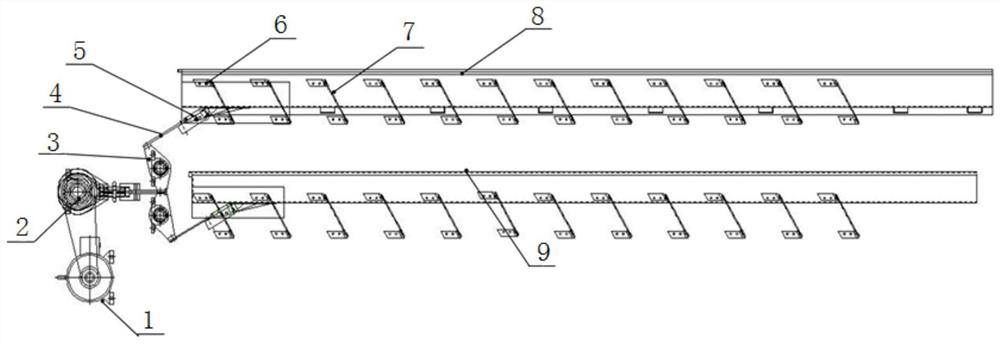

[0036] like image 3 As shown, the double-layer vibrating screen structure of the present application includes a drive motor 1, an eccentric transmission mechanism 2, a V-shaped torque steering assembly 3, a transmission pull tab 4, a drive beam 5, a spring plate support seat 6, a spring plate 7, an upper layer screen 8 and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shaft diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap