Aligning carrier roller set core device

A self-aligning idler and vertical roller technology, applied in the direction of rollers, transportation and packaging, conveyor objects, etc., can solve the problems of increasing time cost and production cost, aggravating the wear and tear of the conveyor belt, and reducing equipment Effects of downtime, reduced conveyor wear, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

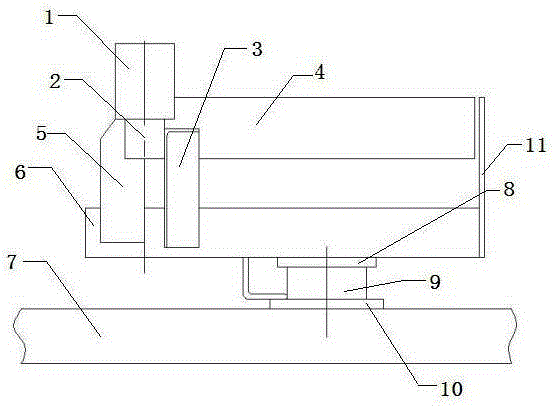

[0013] This embodiment provides a core device of a self-aligning roller group, which is characterized in that: the core device of the self-aligning roller group includes a vertical roller (1), a vertical roller mounting seat (2), a vertical roller rod (3) , idler roller (4), installation support frame (5), upper beam (6), lower beam (7), upper damping pad (8), shaft seat (9), lower damping pad (10), support plate (11); wherein: a shaft seat (9) is provided between the lower beam (7) and the upper beam (6), and a lower shock pad (10) is provided between the shaft seat (9) and the lower beam (7), An upper shock-absorbing pad (8) is provided between the axle seat (9) and the upper beam (6), and a rotating shaft is arranged at the bottom of the upper beam (6). The rotating shaft is installed in the axle seat (9), and one side of the upper beam (6) There is an installation support frame (5), a support plate (11) is provided on the other side, an idler (4) is provided between the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com