Gypsum board fixing and compressing device

A technology for fixing the pressing device and gypsum board, which is applied in the directions of packaging, packaging machine, transportation and packaging, etc. It can solve the problems of scratching the paper surface of the gypsum board, difficulty in replacement, and lower overall efficiency, so as to reduce equipment downtime, Meet the pressing needs and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

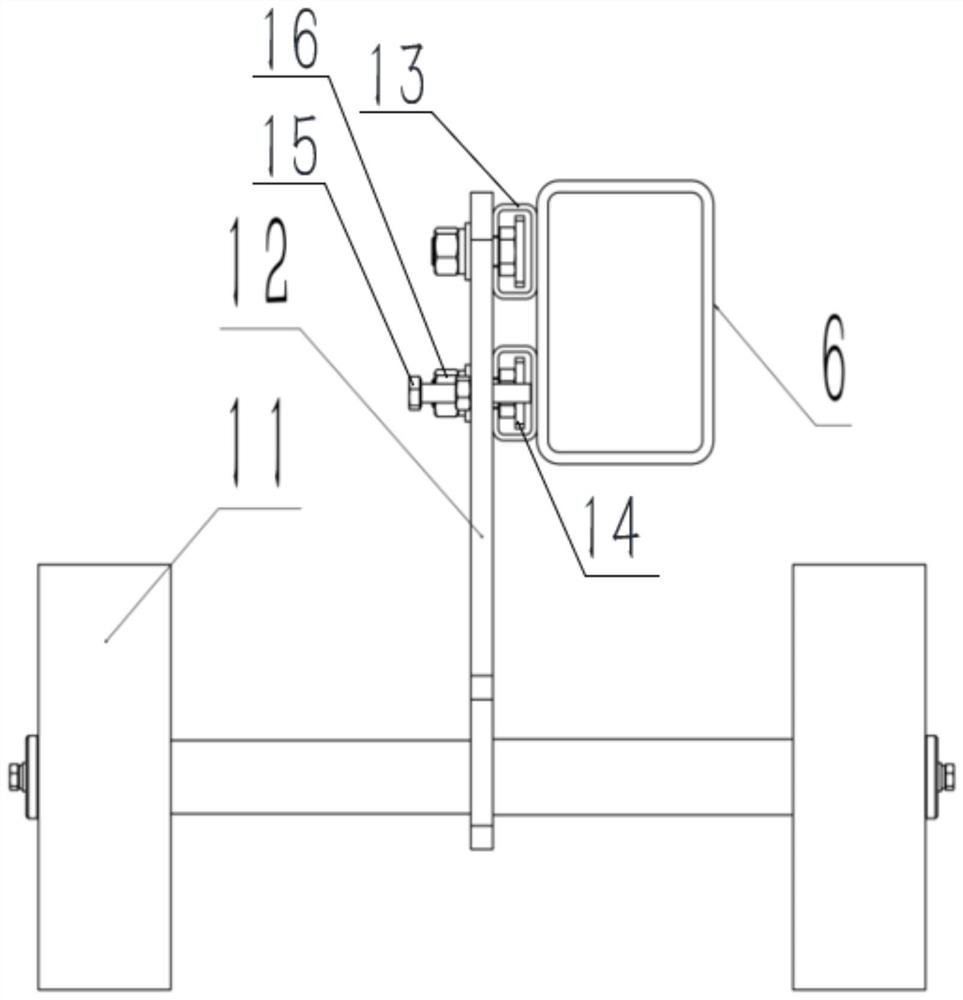

[0029] Embodiment 1, the installation and disassembly of the pressing wheel unit and the fixed beam 6:

[0030] A hanging ear 13 is fixedly connected to the fixed beam 6, and the hanging ear 13 has a "C"-shaped opening, and the hanging plate 12 is connected to the hanging ear 13 through the "C"-shaped opening. A bolt 15 and a second nut 16 are arranged on the hanging plate 12, and a first nut 14 is fixedly arranged in the "C"-shaped opening.

[0031] During installation, the bolt 15 passes through the hanging plate 12, the "C" shaped opening, the first nut 14, and the second nut 16 on the bolt 15 is tightened to realize the connection between the pressing wheel unit 5 and the fixed beam 6.

[0032] During disassembly, the second nut 16 is unscrewed, and the bolt 15 is removed to realize the separation of the pressing wheel unit 5 and the fixed beam 6 .

Embodiment 2

[0033] Embodiment 2, the selection of pressing wheel 11:

[0034] The traditional rigid compression wheel cannot be deformed. When the gypsum board model is replaced, the compression displacement needs to be adjusted continuously; if the compression wheel is made of too soft soft material, it may not be able to meet the compaction process requirements.

[0035] In this implementation, the pressing wheel 11 made of thermoplastic polyurethane elastic material is selected, which has good elastic deformation ability, but the pressing wheel made of thermoplastic polyurethane elastic material has different hardness.

[0036] Hardness is a physical measure of how well a substance deforms under compression or resists puncture. In this embodiment, the Shore hardness is selected to characterize the hardness of the pressing wheel 11 .

[0037] The test method of Shore hardness: Insert the material to be tested with a Shore hardness tester, the pointer on the dial is connected with a nee...

Embodiment 3

[0039] Embodiment 3, manual adjustment of the height of the pressure wheel unit:

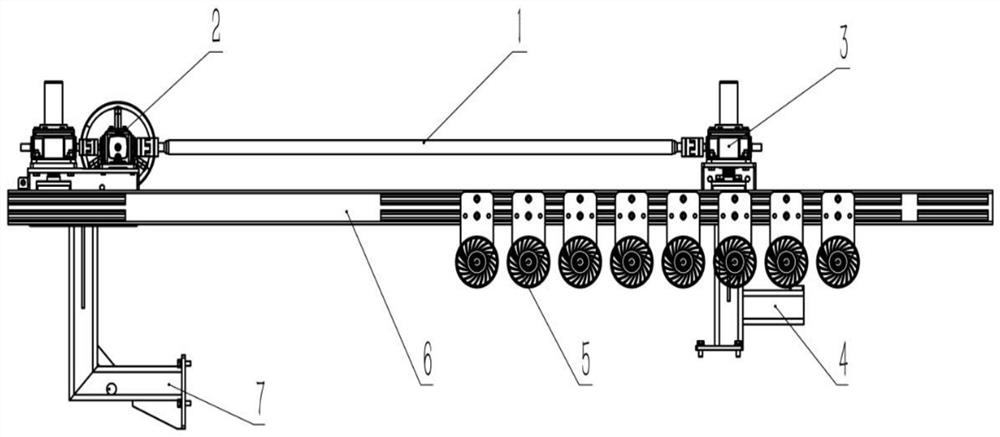

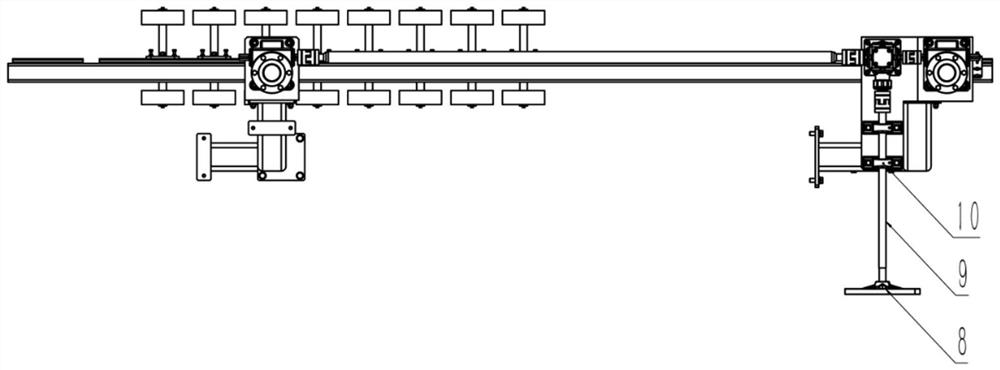

[0040] This device is also provided with a lifting adjustment mechanism for adjusting the lifting of the fixed crossbeam 6. The lifting adjustment mechanism includes an elevator 3, a first transmission shaft 1, and a rocking wheel mechanism. The elevator 3 is provided with a worm gear mechanism and a worm mechanism. The mechanism is connected with the rocker mechanism through the first transmission shaft 1; the fixed beam 6 is mounted on the worm mechanism. The rocking wheel mechanism includes a bearing housing 10 and a second transmission shaft 9 mounted on the bearing housing 10. One end of the second transmission shaft 9 is connected to the hand wheel 8, and the other end is connected to the first transmission shaft 1 through a spiral bevel gearbox 2. .

[0041] In a preferred solution, two elevators 3 are provided, and the spiral bevel gearbox 2 is arranged in the middle of the first transm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com