Blast furnace fan outlet check valve opening test loop

A technology of test circuit and check valve, which is applied in the tuyere, blast furnace, blast furnace details, etc., can solve the problems of large air volume, large pipeline capacity, and fans cannot supply air normally, and achieve the effect of convenient operation and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

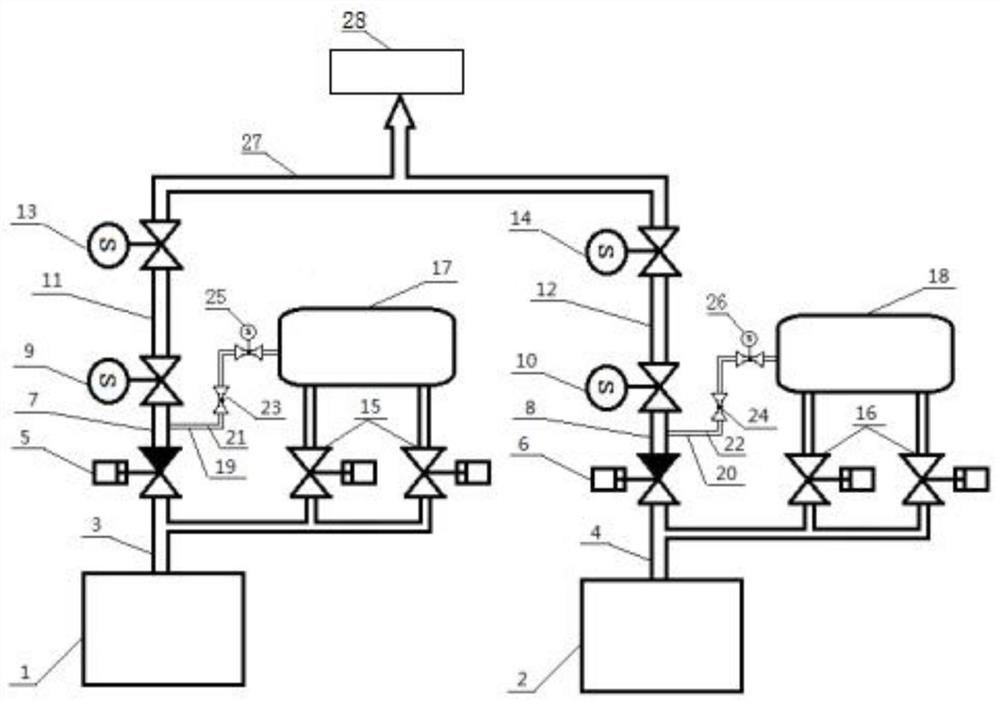

[0027] from figure 1 It can be seen that a blast furnace fan outlet check valve opening test loop of the present embodiment includes a first fan 1, a backup fan 2 and a blast furnace 28. The input end of the blast furnace 28 is connected with an air supply main pipe 27, and the first fan 1 , the standby fan 2 is arranged in parallel at the input end of the air supply main pipe 27;

[0028] The output end of the first fan 1 is connected with a first air outlet duct 7 , and a first check valve 5 , a first air outlet valve 9 , and a first air supply valve 13 are sequentially installed on the first air outlet duct 7 . A first exhaust pressure measuring point 3 is arranged between the return valve 5 and the first fan 1, and a first test pipeline 21 is arranged between the first check valve 5 and the first air outlet valve 9. The first test pipeline The first pressure transmitter 19, the first manual isolation valve 23, and the first test valve 25 are sequentially arranged on the 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap