Pattern sewing machine

A technology of pattern sewing machine and sewing machine head, which is applied in the field of sewing machines, can solve the problems of high preparation cost, bulky size, and invariability, and achieve the effect of dense stitches, low preparation cost, and increased offset speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

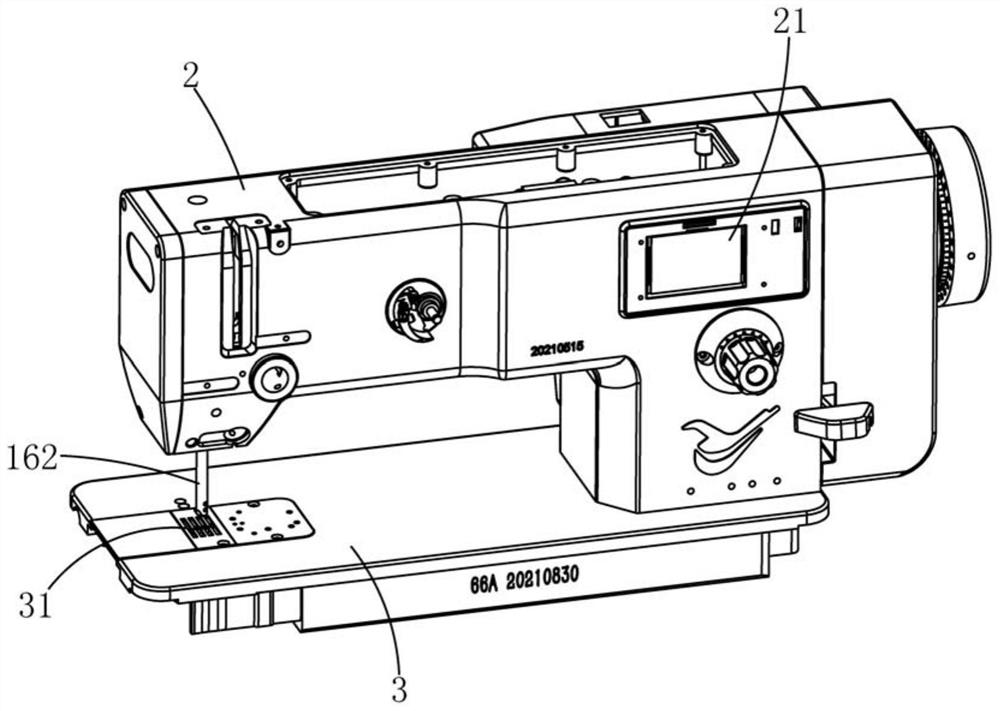

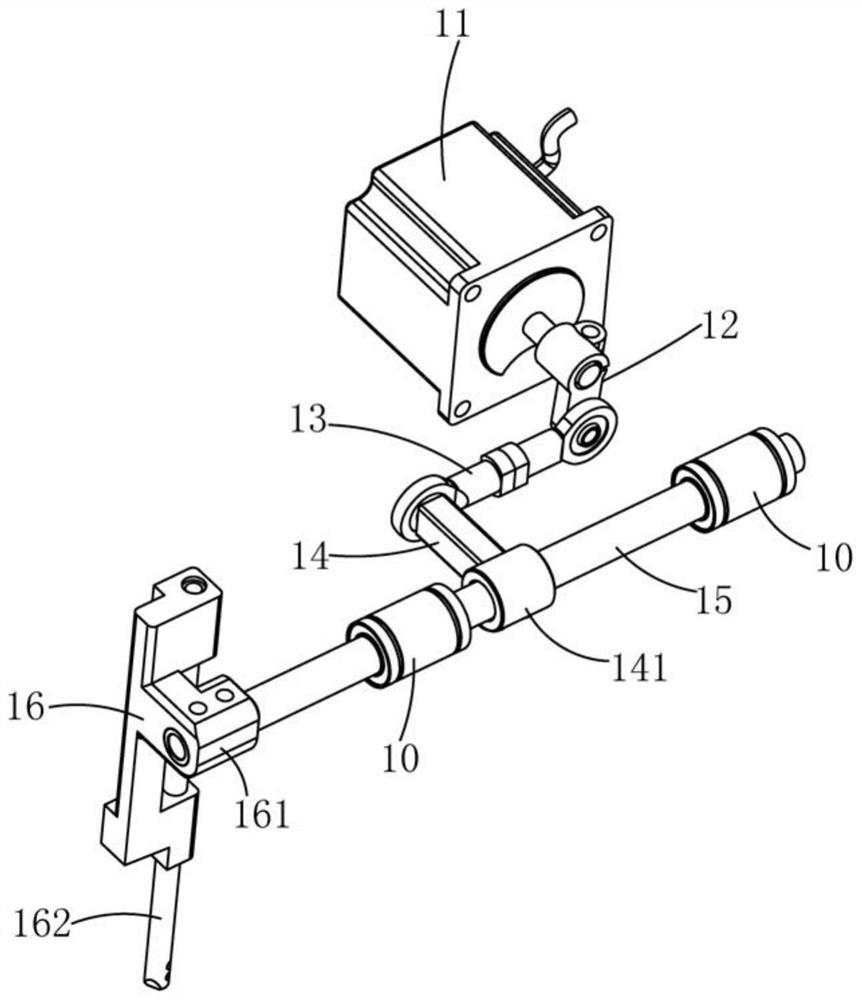

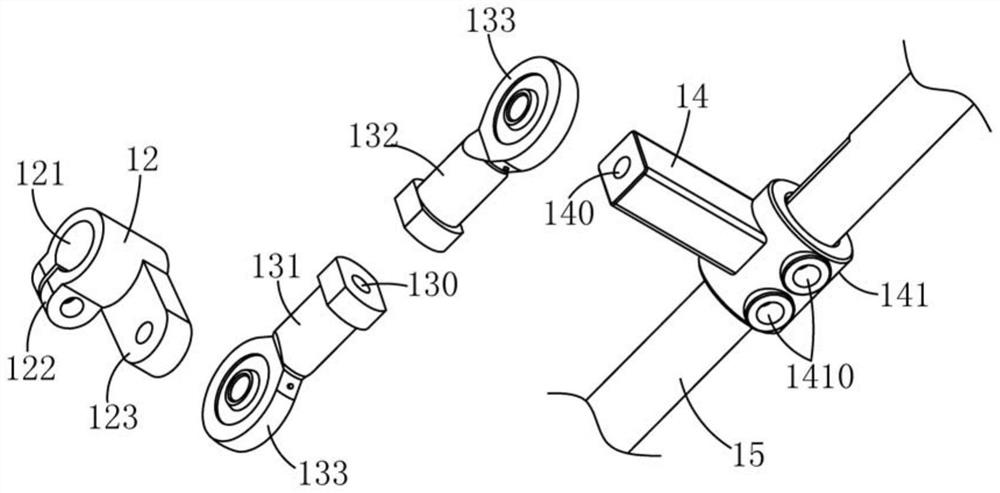

[0027] A pattern sewing machine such as Figure 1 to Figure 3 As shown, it includes a control device 21, a sewing platform 3 and a sewing machine head 2 fixed on the surface of the sewing platform 3. The sewing platform 3 is provided with a supporting base plate 31, and the supporting base plate 31 is provided with a longitudinal feeding mechanism. The inside of the sewing machine head 2 There is a needle frame 16 for assembling threading needles, the needle frame 16 is located directly above the support base plate 31, the needle frame 16 is movable along the horizontal direction, and the needle frame 16 is connected with a bias drive mechanism, a bias drive mechanism and a longitudinal feeding mechanism The control device 21 is electrically connected respectively; wherein, the bias drive mechanism includes a bias drive motor 11 and a connecting rod structure, and the connecting rod structure includes a swing rod 12, a first connecting rod 13, a second connecting rod 14 and a t...

Embodiment 2

[0039] like Figure 8 As shown, the structure of the pattern sewing machine shown in this embodiment is basically the same as that shown in Embodiment 1, the difference is that the top of the needle frame 16 in this embodiment is pivotally connected to the sewing machine head 2, and the needle The frame 16 is installed on the sewing machine head 2 in a swinging state, and the needle frame 16 is driven by the biasing drive mechanism to make a swing offset at a set angle, so as to complete the transformation of different threading positions, so as to realize the above-mentioned sewing pattern 1, sewing pattern 2 and others. Sewing pattern; wherein, the bias drive mechanism includes a swing rod 12, an extension rod 61 and a swing link 6, the first end of the swing rod 12 is fixed to the output shaft of the bias drive motor 11, and the other end of the swing rod 12 It is fixedly connected with the first end of the extension rod 61, and the swing rod 12 and the extension rod 61 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com