High-voltage cable aluminum sheath protective belt take-up and pay-off device

A technology of retractable device and protective belt, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of aluminum sheath not wear-resistant, difficult, lack of protective belt retractable device, etc., to achieve protection from wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

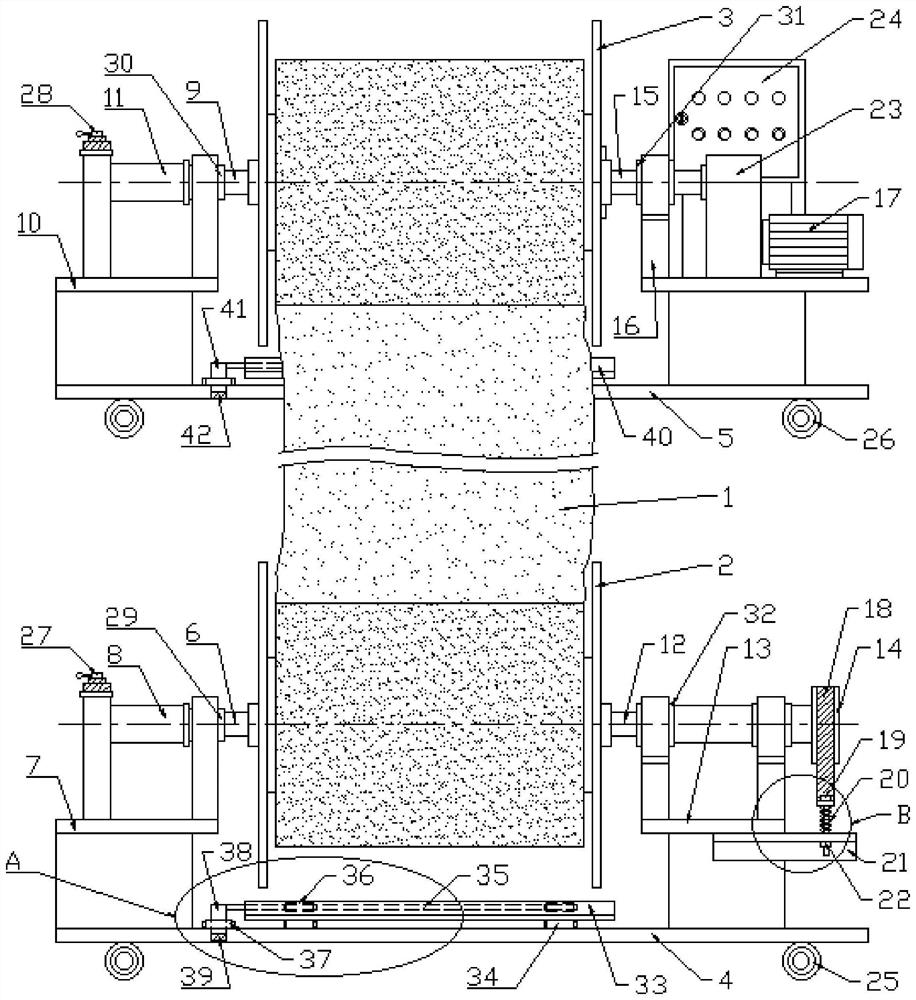

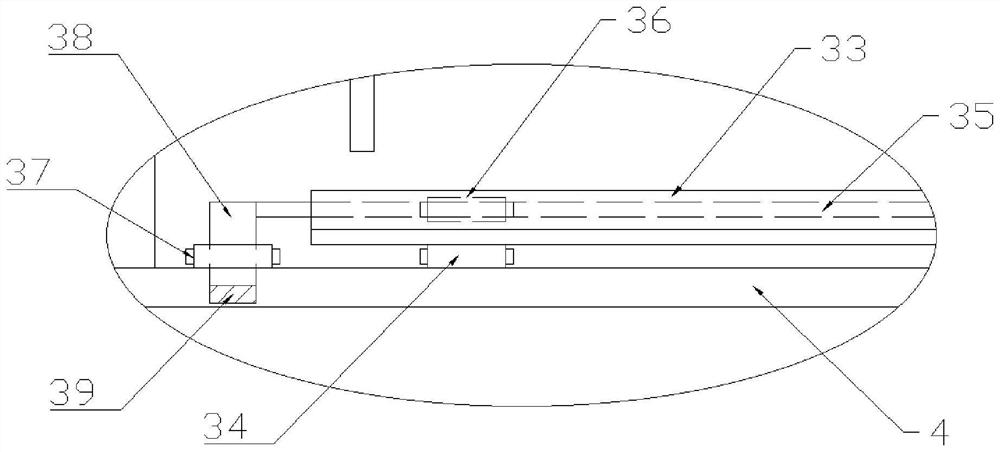

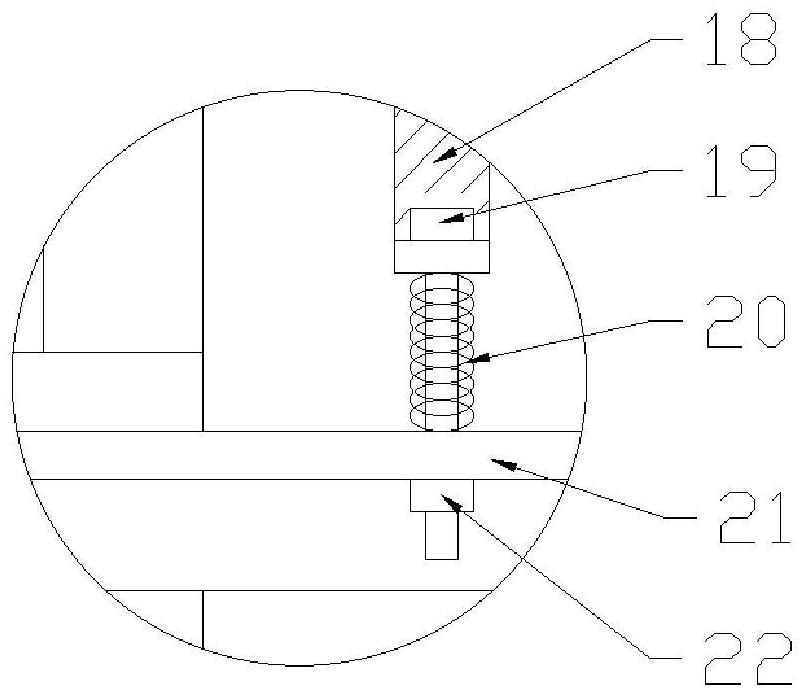

[0023] like Figure 1-3 As shown, a high-voltage cable aluminum sheath protective belt retracting and unwinding device includes a protective belt 1, a winding reel 2 for unwinding the protective belt, a winding reel 3 for rewinding the protective belt, and a protective belt. An unwinding trolley with unwinding and a winding trolley used for protective belt winding; the unwinding trolley includes a chassis 4, and the upper left and right ends of the chassis 1 are respectively provided with a 1 for lifting the winding drum. The reel changing shaft assembly 1 and the driven shaft assembly; the reeling trolley includes a chassis two 5, the upper left and right ends of the chassis two are respectively provided with a reel changing shaft assembly two for lifting the winding reel two and Drive shaft assembly; the first barrel changing shaft assembly includes a barrel changing shaft 1 6 and a support frame 1 7 fixed above the chassis 1, the barrel changing shaft 1 is slidably horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com