Fine seeding machine for peanut field breeding

A precision sowing machine and peanut technology, which is applied to interval quantitative sowing machinery, planter parts, single-seed planters, etc., can solve problems such as high labor intensity, unguaranteed operation accuracy, and damage to peanut seeds, and achieve Ensure the stability of seeding, good water and moisture retention, and good driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

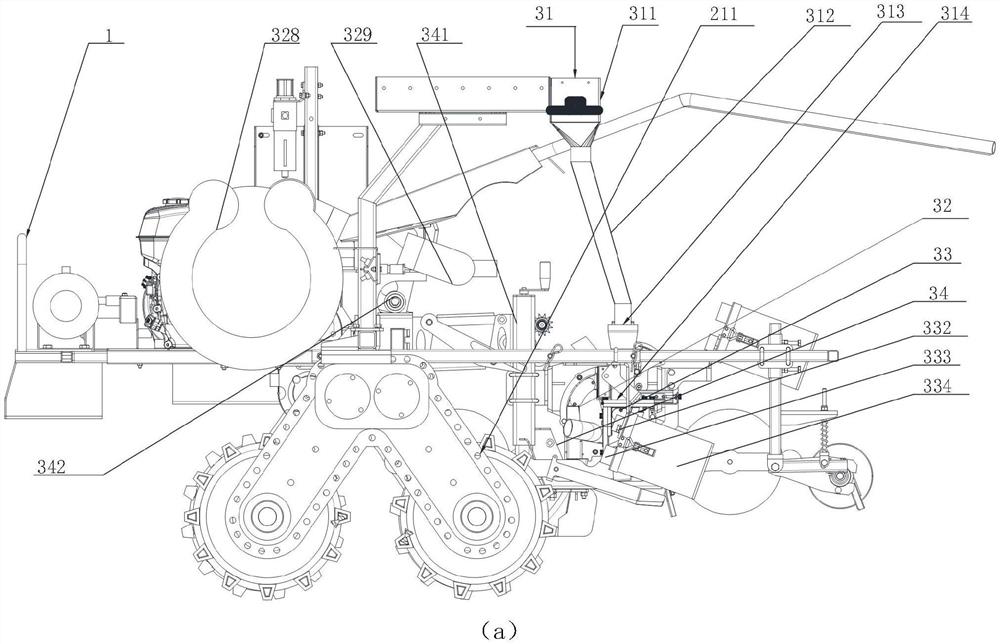

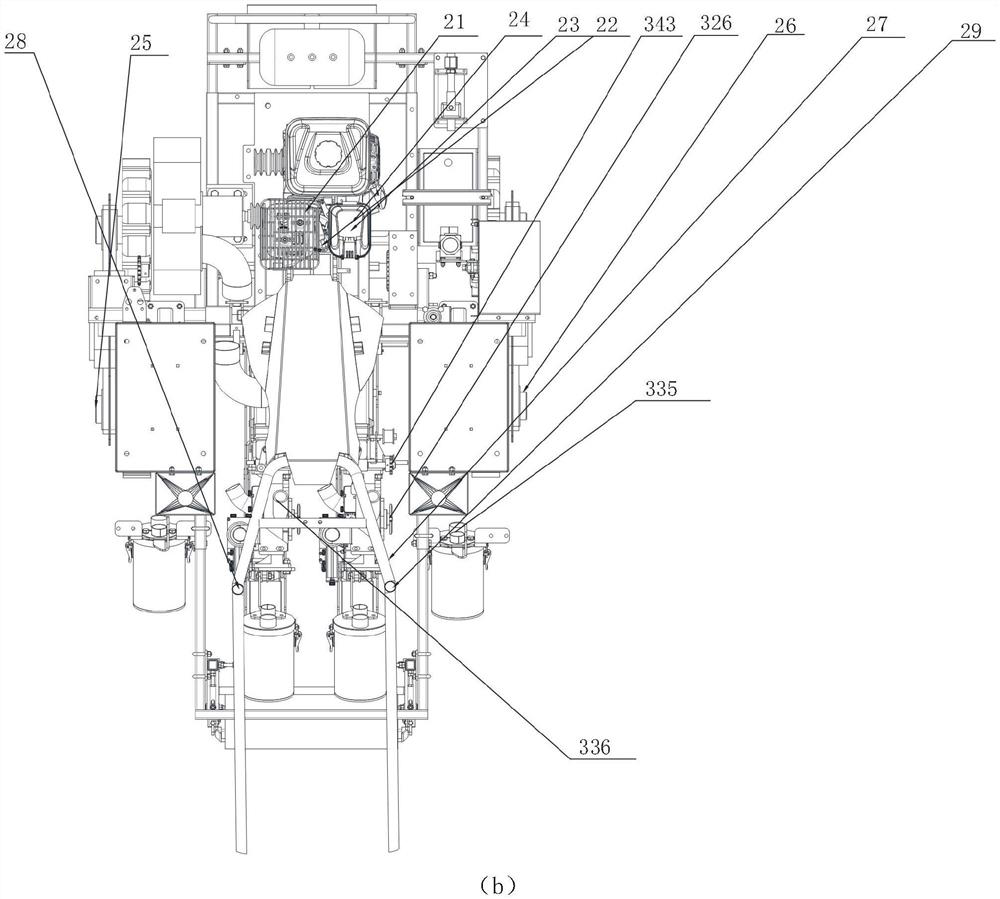

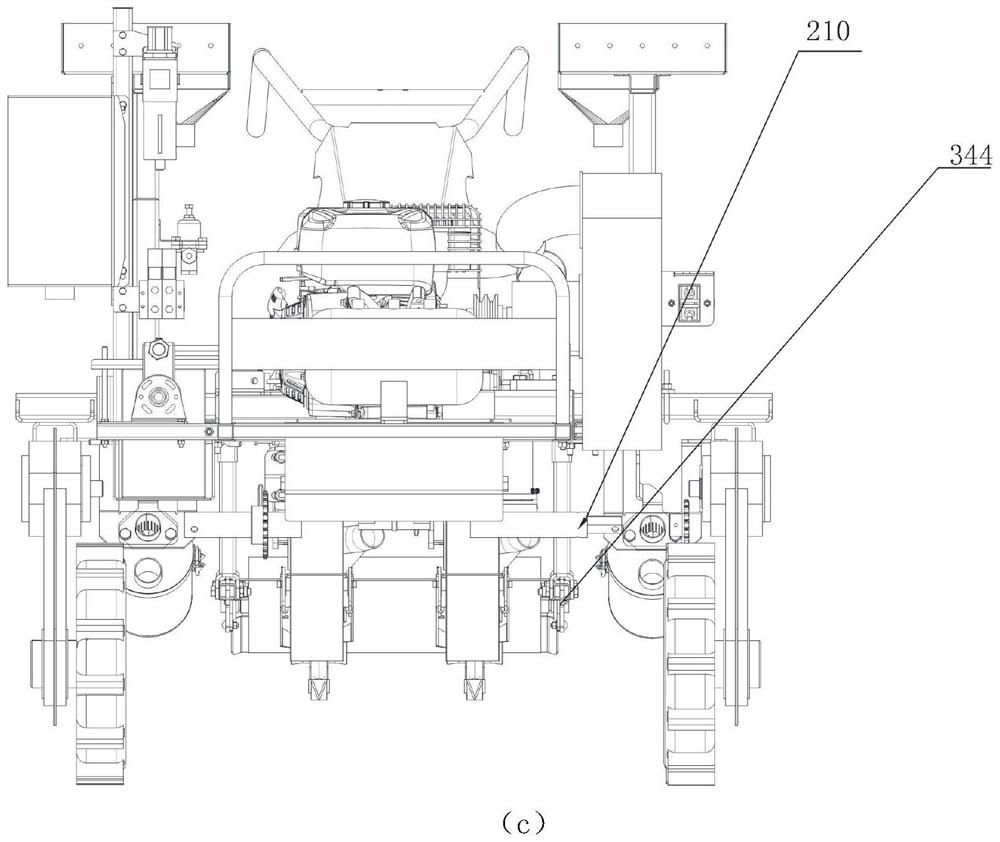

[0021] In order to more clearly understand the above objects, features and advantages of the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments. In the following description, many specific details are set forth in order to facilitate a full understanding of the present invention. However, the present invention may also be implemented in other ways than those described herein. Therefore, the present invention is not limited to the specific embodiments disclosed below. , It should be noted that the definition of directions such as front, rear, left and right is based on the forward direction of the planter.

[0022] Aiming at the problems that the current peanut field breeding planters in the current community have different adaptations to seeds, the mechanization degree of the seeder is low, and the operating parameters of the seeding device cannot be adjusted, etc., resulting in poor sowing qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com