Barrel-shaped nut mounting tool and using method thereof

A technology for installing tools and nuts, which is applied in the field of machinery, can solve problems such as abnormal or interference of the arched edge of the frame, difficulty in manual installation of barrel nuts, etc., and achieve the effects of avoiding deformation and interference, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

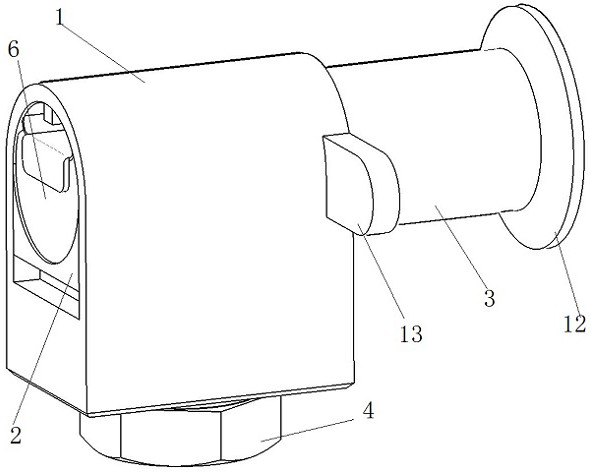

[0033] This embodiment provides a barrel nut installation tool, such as figure 1 As shown, it includes a sleeve 1 , a lower support 2 , a top rod 3 and a limiting member 4 .

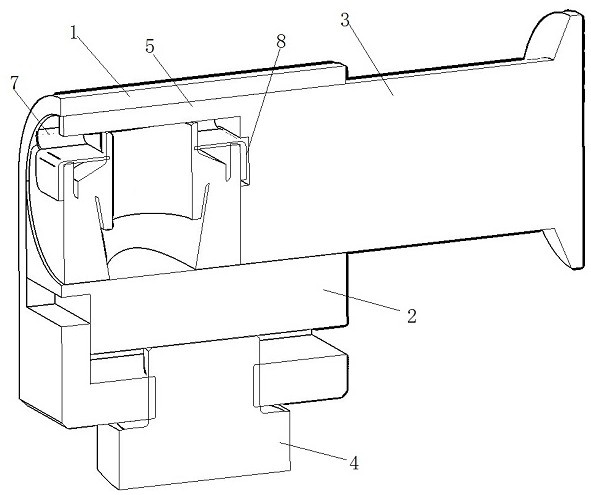

[0034] Sleeve 1 is a hollow structure with openings at both ends, its upper half is a cylindrical structure with a partial arc surface inside, the lower half is a square base, and the upper half and the lower half are connected into a single structure. overall.

[0035] like figure 2 As shown in the figure, the lower support 2 is slidably connected inside the sleeve 1, and its bottom is slidably connected with the square base of the lower half of the sleeve 1 through a stepped structure. The part of the arc surface is opposite to the concave arc surface. The bottom of the square base is provided with threaded holes, and the limiting part 4 passes through the threaded holes at the bottom of the sleeve 1 and contacts with the lower support 2, and is used to adjust and fix the concave arc surface on the...

Embodiment 2

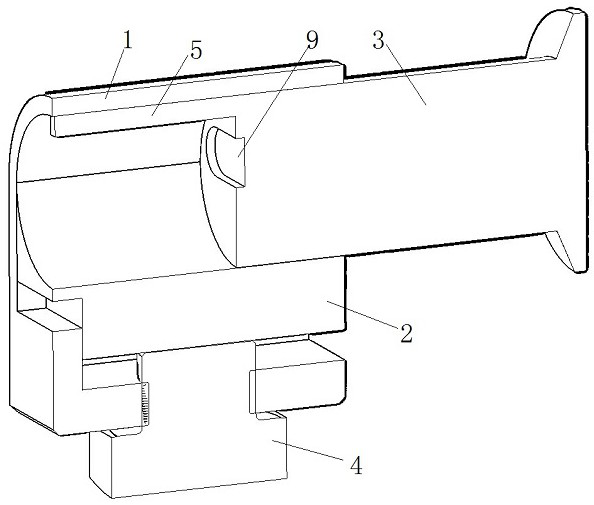

[0045]This embodiment provides a barrel nut installation tool. On the basis of Embodiment 1, further, the end of the ejector rod 3 in contact with the barrel nut assembly is provided with an escape groove 9, and the escape groove 9 just accommodates The elastic piece 8 protruding from the end face of the barrel nut assembly 6 side. In the process of pushing the ejector rod 3, the front end surface of the ejector rod 3 can be better contacted with the side end surface of the barrel nut assembly 6, so that it can bear the force better.

[0046] Preferably, in order to push the ejector rod 3 conveniently and labor-savingly, the end of the ejector rod 3 away from the barrel nut assembly is provided with a push handle 12 that is easy to hold, and the outer side of the sleeve 1 close to the ejector rod 3 is provided with a booster Connection ear 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com