Integrated blanking equipment for automobile panel

A panel and integrated technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of reducing production efficiency, leaving burrs or margins, etc., and achieve the effects of improving production efficiency, reducing precision requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

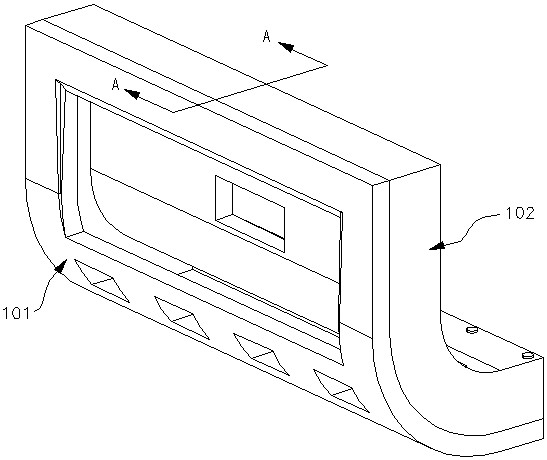

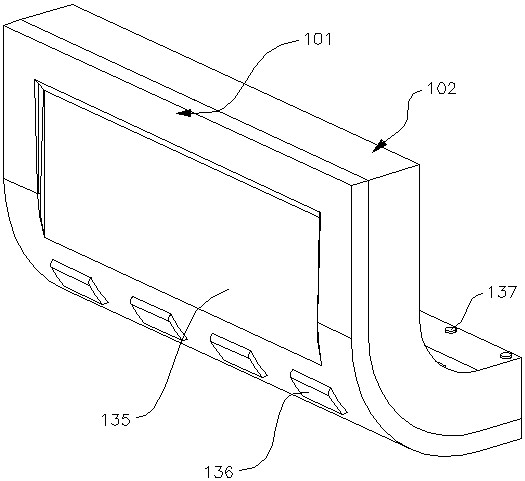

[0040] The automobile panel provided in Embodiment 1 adopts a separate assembly structure of the front panel 101 and the rear cover panel 102, which can constrain the circuit board and the data lines inside the first chamber 111 and the second chamber 112, which solves the problem in the prior art. The following technical problems: After the car panel is installed, the circuit board and data lines are exposed on the back of the car panel, occupying the interior space of the console, affecting other electronic components and data lines inside the console, which is not conducive to assembly and maintenance. ; The front panel 101 and the rear cover 102 are still in the L-shaped plate structure as a whole, and the overall occupied space is reduced after the installation is completed, and the structure is more compact compared to the vehicle panel in the prior art and its installation method.

[0041] On the other hand, the overall upper surface of the front panel 101 is smooth, whi...

Embodiment 2

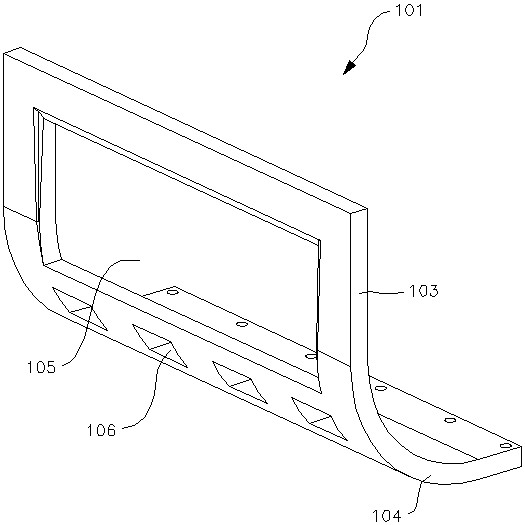

[0047] The integrated punching equipment provided in Embodiment 2 can punch the automotive panel described in Embodiment 1 at one time, and remove the residual burrs or margins on the edges of the main window 105, the secondary window 106, and the cable window 110, thereby reducing the need for injection molding. The precision of the mold is required, thereby reducing the production cost, and improving the production efficiency compared with the manual punching in the prior art.

[0048] In some implementations of Example 2, a front molding plane 121 and a front molding cylindrical surface 122 are provided inside the second cavity 120 , and the front molding plane 121 is tangent to the front molding cylindrical surface 122 . The central angle of the front forming cylindrical surface 122 is 90 degrees, the diameter of the front forming cylindrical surface 122 is equal to the diameter of the outer surface of the front cylindrical surface 104 , and the front forming plane 121 is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com