Combined spreader in multicolor die head

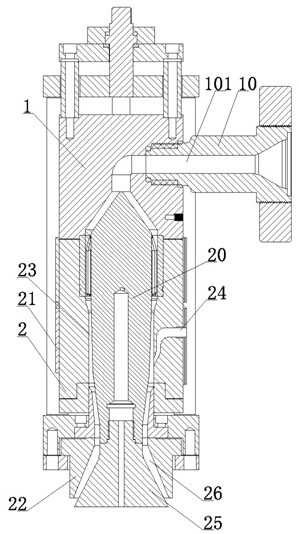

A combined and shunting shuttle technology, which is applied in the field of blow molding machines, can solve problems such as color difference and difficulty in making plastic products, and achieve the effects of improving aesthetics, convenient installation, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

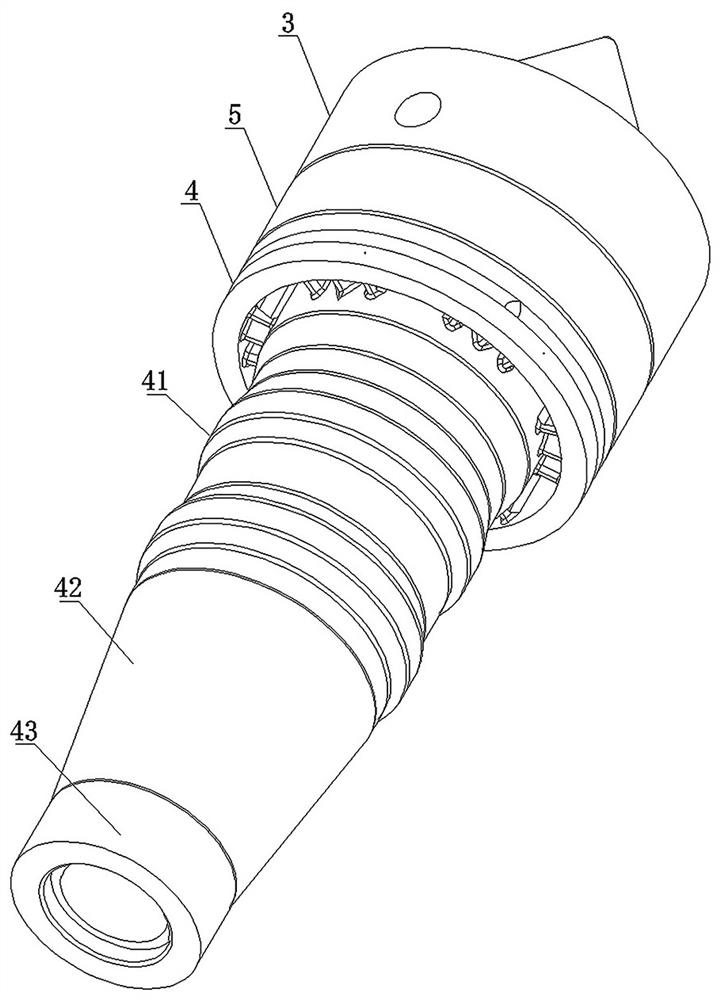

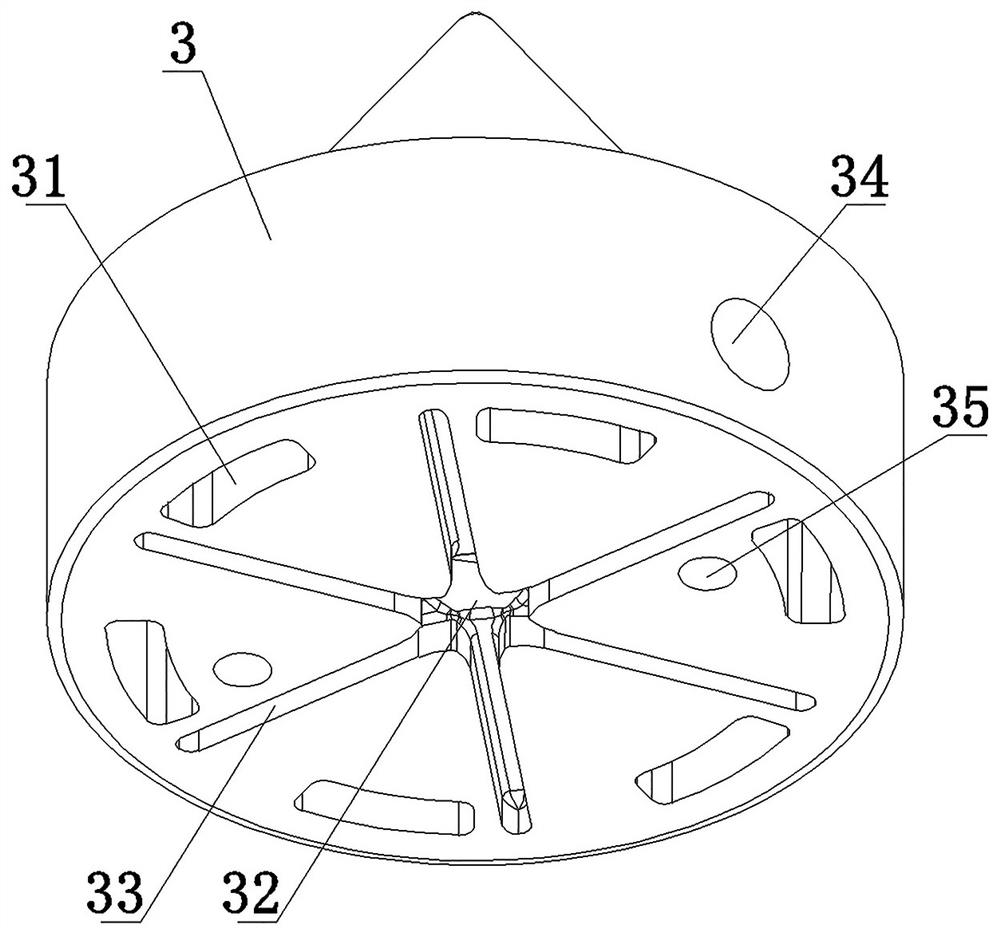

[0025] When it is necessary to blow plastic products with two-color twelve stripes, such as Image 6 As shown in the figure, the combined diverter shuttle used is composed of a conical diversion disc 3 and a diversion column 4 which are sealed and matched, and the two first connection holes 35 on the conical diversion disc 3 are respectively connected with the two The second connection holes 46 are in one-to-one correspondence, connecting rods 6 are pierced between the corresponding first connection holes 35 and the second connection holes 46 , six One guide hole 31, six first distribution grooves 33;

[0026] There are six third guide holes 44 corresponding to the six first guide holes 31 one-to-one, and six second guide holes 44 corresponding to the six first guide holes 33 one-to-one on the top wall of the distribution column 4 . shunt hole 45;

[0027]When using this type of combined diverter shuttle, it is necessary to set up a dichroic flow channel corresponding to the...

Embodiment 2

[0029] When it is necessary to blow plastic products with eighteen stripes in three colors, such as Figure 7 As shown in the figure, the combined diverter shuttle used is composed of a conical diversion disc 3, a diversion disc 5 and a diversion column 4 in order from top to bottom. The two first connection holes 35 on the conical diversion disc 3 They are in one-to-one correspondence with the two connecting through holes 56 on the shunt plate 5, and the two connecting through holes 56 on the shunt plate 5 are in one-to-one correspondence with the two second connecting holes 46 on the shunt column 4. A connecting rod 6 is pierced between the connecting hole 35 , the connecting through hole 56 and the second connecting hole 46 , and six first guide holes 31 , six third guide holes 31 are evenly distributed on the bottom wall of the conical guide plate 3 . A shunt 33;

[0030] There are six second diversion holes 51 corresponding to the six first diversion holes 31 one-to-one,...

Embodiment 3

[0034] When it is necessary to blow plastic products with four colors and twenty-four stripes, such as Figure 8 As shown in the figure, the combined diverting shuttle used is composed of a conical diversion disc 3, two diverting discs 5 and a diverting column 4 in order from top to bottom. The two first connection holes on the conical diversion disc 3 35 are in one-to-one correspondence with the two connecting through holes 56 on the shunt plate 5, and the two connecting through holes 56 on the shunt plate 5 are in one-to-one correspondence with the two second connecting holes 46 on the shunt column 4. A connecting rod 6 is pierced between the first connecting hole 35 , the connecting through hole 56 and the second connecting hole 46 , and six first guide holes 31 , six first guide holes 31 , six the first shunt 33;

[0035] The first diverter plate 5 is uniformly distributed with six second diversion holes 51 corresponding to the six first diversion holes 31 one-to-one, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com