Lubricating system capable of prolonging service life of valve copper bush and working method of lubricating system

A lubricating system and copper sleeve technology, applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve problems such as valve jamming or damage, achieve uniform force, good applicability, and reduce maintenance workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail, and its content is to explain rather than limit the present invention:

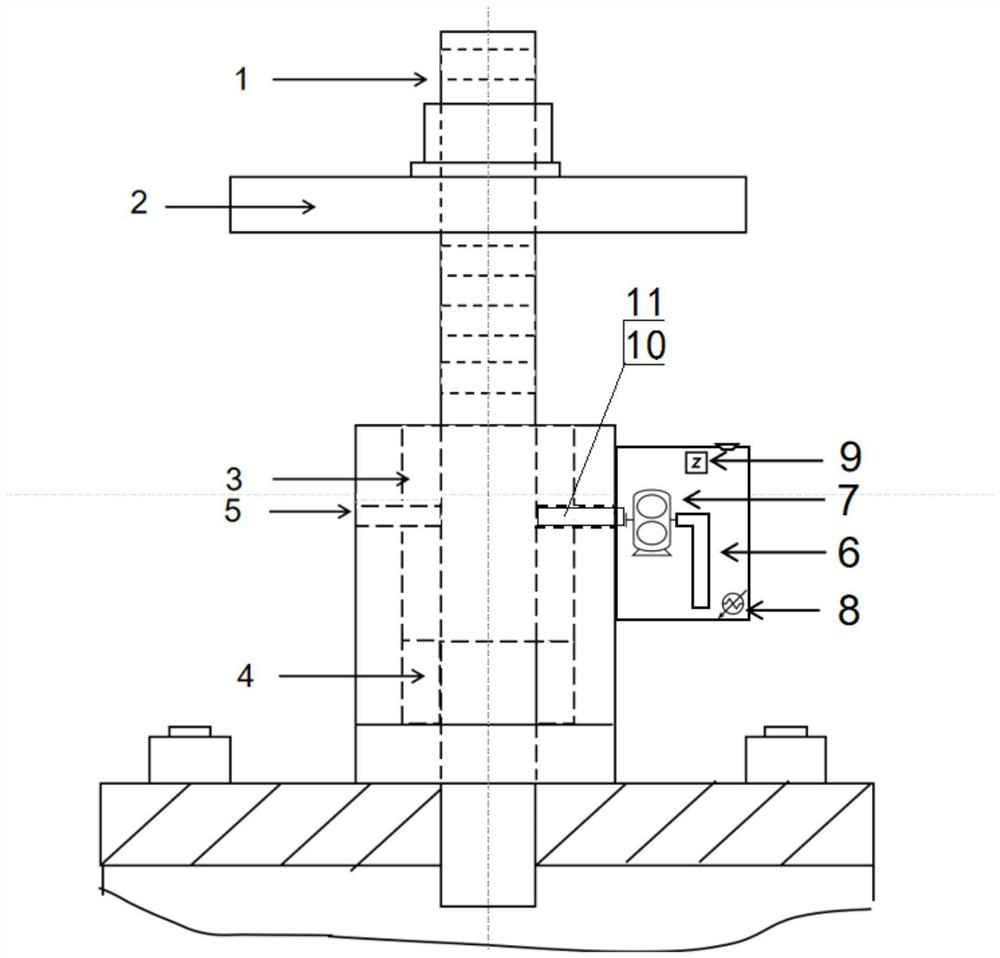

[0029] like figure 1 , is a typical valve structure, including door stem 1, handwheel 2, copper sleeve 3, valve cover 4, one side is equipped with copper sleeve locating pin 5, for newly manufactured valves, the oil injection hole 10 is machined on the opposite side ; For the existing valve, transform the pin hole of the copper sleeve positioning pin 5 on the other side into an oil filling hole 10 and insert the oil filling pipe 11. The depth of the oil injection hole 10 penetrates through the inner ring of the copper sleeve 3 , and the aperture size is the same as that of the oil injection pipe 11 .

[0030] The lubricating system for prolonging the life of the valve copper sleeve of the present invention includes a casing 6, an oil delivery pump 7, a heater 8, a timer 9, an oil injection hole 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com