Laser cutting equipment with dustproof heat dissipation box

A laser cutting and cooling box technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of dust and debris entering the control box, affecting the smooth cutting, and damage to internal components, so as to maintain ventilation Heat dissipation effect, convenient and fast removal, good for collection and adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

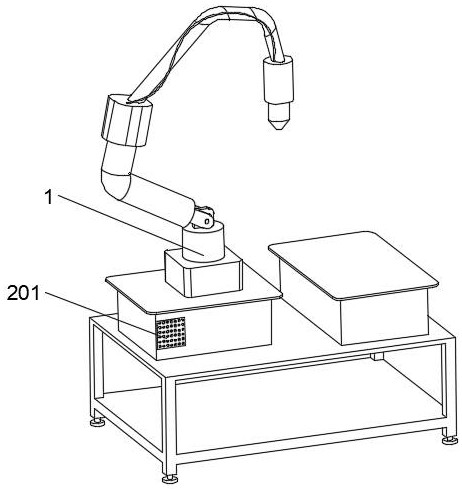

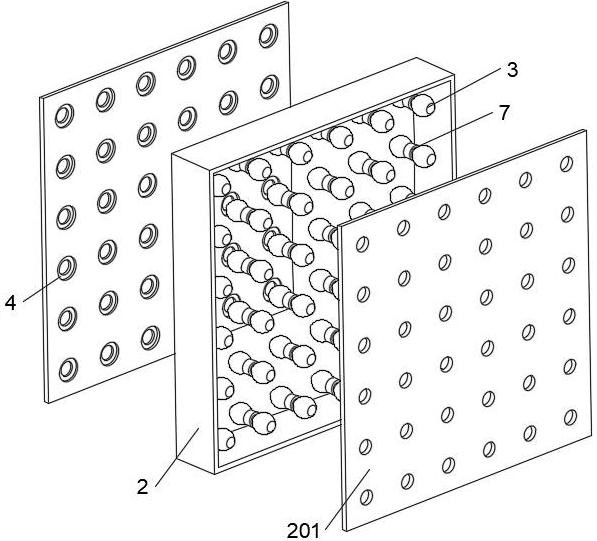

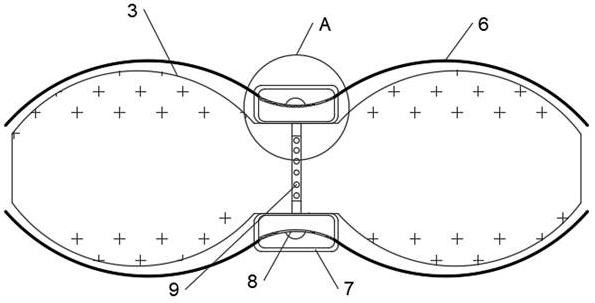

[0042] see Figure 1-Figure 10 , a laser cutting device with a dust-proof heat dissipation box, including a laser cutting device body 1, a heat dissipation channel 2 is fixedly installed on the laser cutting device body 1, and a ventilation plate 201 is fixedly connected to the front and rear ends of the heat dissipation channel 2 symmetrically. A plurality of air-distributing films 3 are fixedly connected between each ventilation plate 201, and a side of the ventilation plate 201 at the rear end close to the heat dissipation channel 2 is provided with a plurality of peeling ring placement grooves 4, and the sides of the two ventilation plates 201 are close to each other. A plurality of micro-heating sheets 5 are fixedly installed, and the side of the micro-heating sheets 5 close to the heat dissipation channel 2 is fixedly connected with a plurality of heat-sensitive driving ropes 6, and an extruded peeling ring 7 is slidably connected in the peeling ring placement groove 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com