Device and method for detecting bending degree and warping degree of sealing ring

A detection device and sealing ring technology, which is applied in the direction of mechanical counter/curvature measurement, mechanical solid deformation measurement, etc., can solve the problems of inability to detect the bending degree and warpage of the sealing ring, reduce the detection effect, and increase the detection cost of the sealing ring. , to achieve the effects of improving detection and feeding effects, improving detection effects, and facilitating merging and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

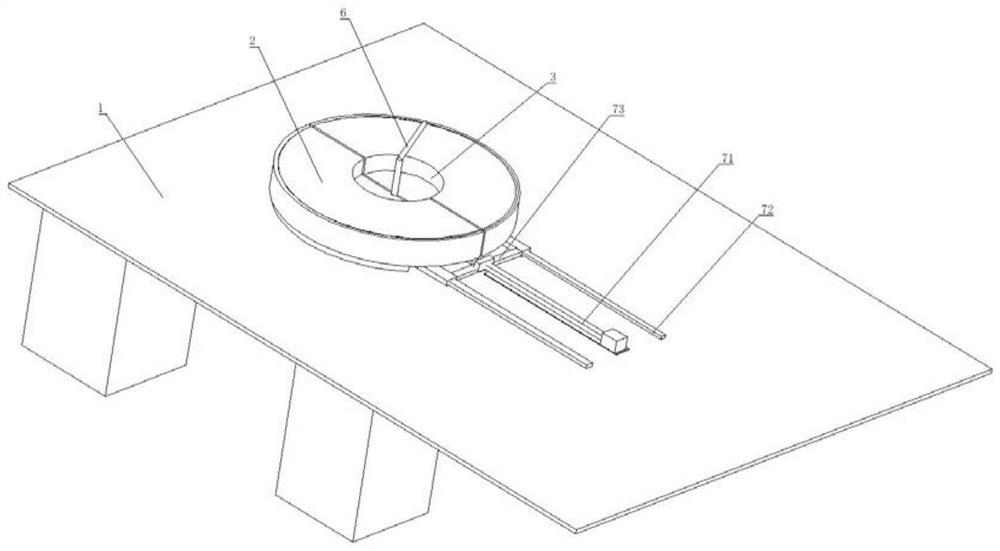

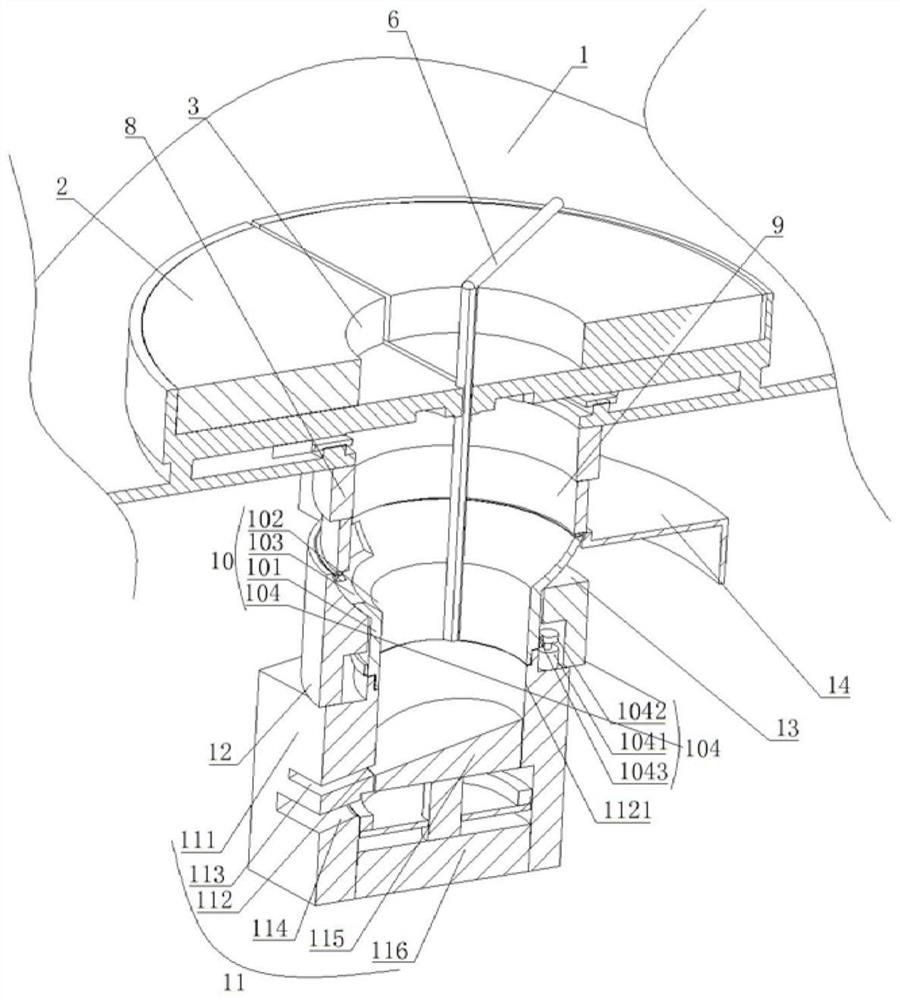

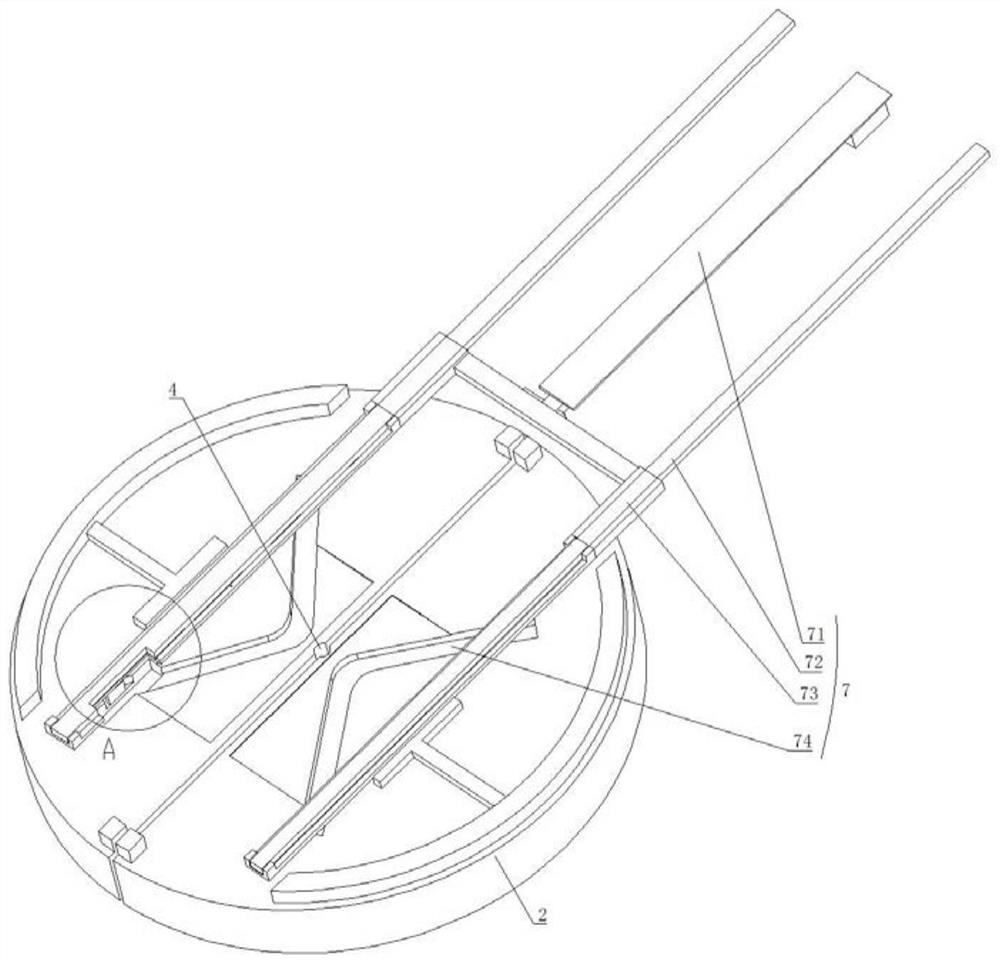

[0028] like Figure 1-5 As shown in the figure, a detection device for the curvature and warpage of a sealing ring includes a detection seat 1, and the detection seat 1 is provided with two half-disks 2 arranged opposite to each other, and a placement port 3 is provided on the top of the side of the half-disk 2. , a pre-installation port 4 is opened at the edge of the placement port 3. When the two semi-disks 2 are merged, the two pre-installation ports 4 form a pre-installation hole 5, and a pre-installation hole 5 is provided in the pre-installation hole 5 for passing the sealing ring. The rod 6 is installed, the detection seat 1 is provided with a drive mechanism 7 for driving the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com