Control method and driving system of electric control three-way valve in fuel cell thermal management system

A thermal management system, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as inaccurate temperature control, and achieve the effect of ensuring control accuracy, saving manpower and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

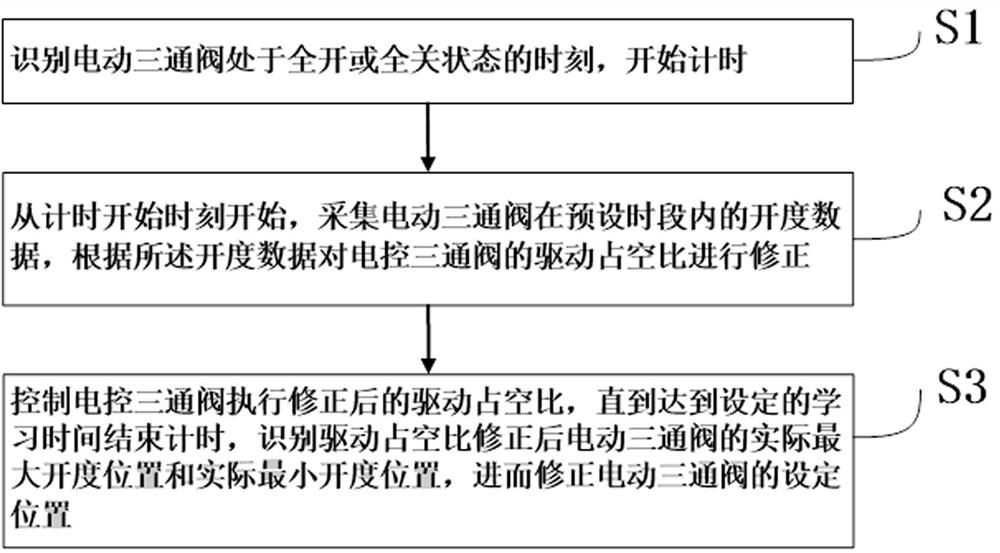

[0053] An embodiment of the present invention discloses a control method for an electronically controlled three-way valve in a fuel cell thermal management system, such as figure 1 shown, including the following steps:

[0054] S1. Identify the moment when the electric three-way valve is in the fully open or fully closed state, and start timing;

[0055] S2. From the timing start time, collect the opening degree data of the electric three-way valve within the preset time period, and correct the driving duty ratio of the electrically controlled three-way valve according to the opening degree data;

[0056] S3. Control the electronically controlled three-way valve to execute the corrected drive duty cycle until the set learning time is reached, and identify the actual maximum opening position and actual minimum opening position of the electric three-way valve after the drive duty cycle is corrected. , and then correct the set position of the electric three-way valve (set the ma...

Embodiment 2

[0060] On the basis of embodiment 1, improve, also include the following steps:

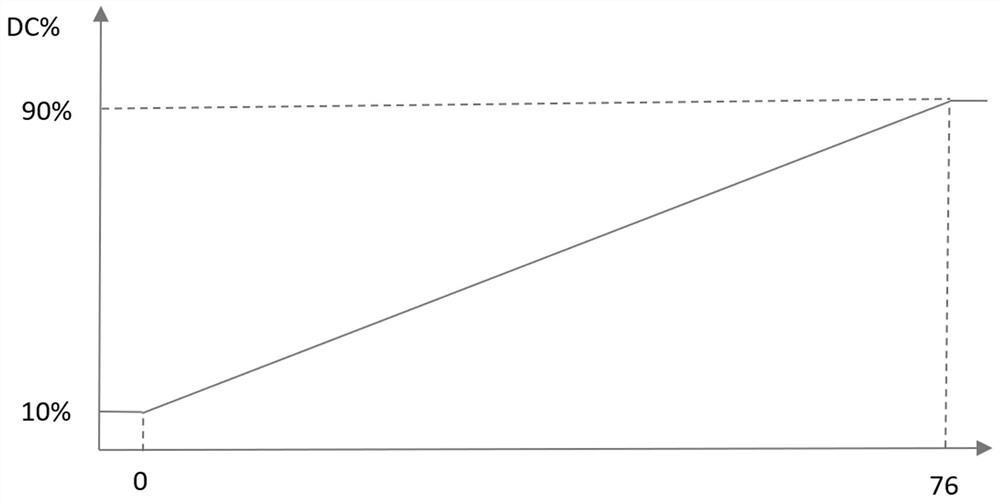

[0061] S01. Determine the characteristic curve of the opening degree of the electric three-way valve changing with the number of switches, such as figure 2 shown;

[0062] S02. According to the above characteristic curve, determine the time period during which the electric three-way valve enters the self-learning correction, as well as the initial learning time t0, learning time t1, maximum opening B1, and minimum opening B2 in each time period; Each time the opening degree change rate of the three-way valve decreases by a fixed ratio, a self-learning correction is performed, and the learning time t1 is greater than an integer multiple of the drive period set by the factory. The maximum opening B1 and the minimum opening B2 are also the initial installed values provided by the electric three-way valve manufacturer.

[0063] Preferably, during each self-learning correction, the preset time pe...

Embodiment 3

[0085] The present invention also discloses a driving system for an electronically controlled three-way valve in a fuel cell thermal management system corresponding to the method in Embodiment 1 or 2, comprising a controller and an electronically controlled three-way valve connected in sequence.

[0086] The controller is used to control the start of the electronically controlled three-way valve; and, after the electronically controlled three-way valve is started, identify whether to enter the self-learning correction stage; if so, identify the moment when the electric three-way valve is in a fully open or fully closed state, Start timing, collect the opening data of the electric three-way valve within the preset time period from the time when the timing starts, and correct the driving duty ratio of the electronically controlled three-way valve according to the opening data, and then control the electronically controlled three-way valve. The through valve executes the corrected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com