Intelligent building waste sorting equipment based on Internet of Things

A technology of construction waste and the Internet of Things, which is applied in the direction of solid waste removal, conveyor objects, cleaning methods and utensils, etc., can solve the problems of increasing the workload of staff and wasting labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

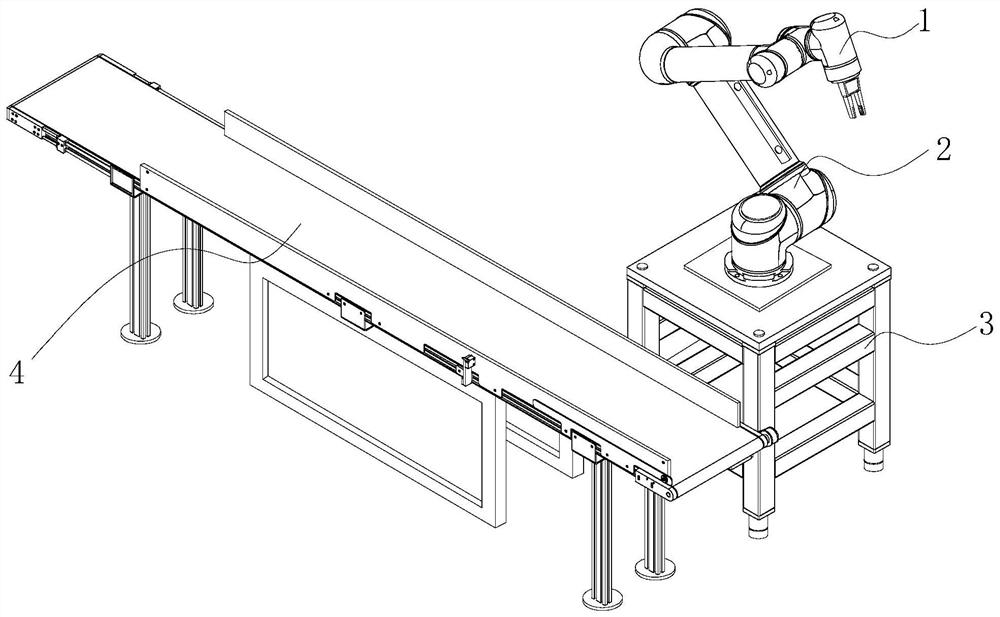

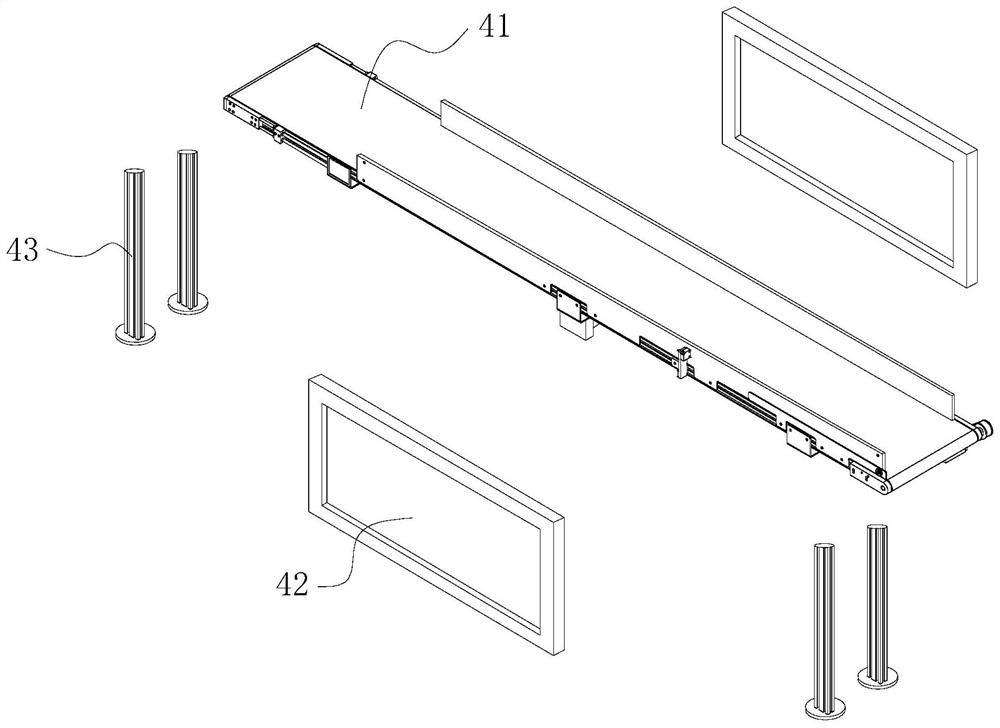

[0035] like Figure 1 to Figure 10 shown:

[0036] The present invention provides an intelligent sorting equipment for construction waste based on the Internet of Things. In the top position, the linkage arm 2 and the supporting frame 3 are movably engaged, and the transmission frame 4 is fixed at the side position of the supporting frame 3; The stabilizing plate 42 is fixed at the bottom position of the transmission mechanism 41 , and the base bracket 43 is embedded at the bottom position of the transmission mechanism 41 .

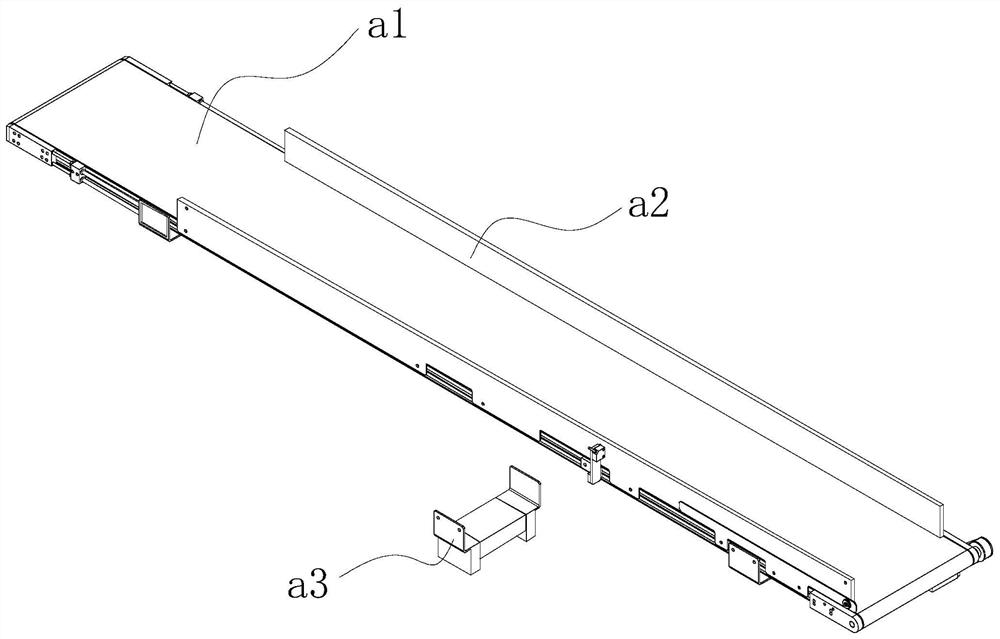

[0037] The transmission mechanism 41 includes a conveyor belt a1, a protective plate a2, and a scraping block a3. The protective plate a2 is fixed on the side of the conveyor belt a1, and the scraping block a3 is fixed on the bottom position of the conveyor belt a1. The upper surface of the scraping block a3 is in contact with the lower surface of the conveyor belt a1 , so that the scraping block a3 can scrape the concrete rotated to the bottom of the c...

Embodiment 2

[0045] like Figure 11-Figure 15 shown:

[0046] Wherein, the block b21 includes a bottoming block f1, a guide groove f2, and a middle plane f3, the guide groove f2 is embedded in the inner position of the middle plane f3, and the middle plane f3 is fixed on the bottom of the bottom block f1. The upper surface is in the middle position, and the inner wall of the guide groove f2 is inclined, so that the dust can be discharged to the outside along the guide groove f2, and the friction between the middle surface f3 and the inner wall of the mechanism during sliding along the inner wall of the mechanism is also reduced. Dust that has not entered the inside of the guide groove f2 can be swept into the inside of the guide groove f2.

[0047] The bottoming block f1 includes a bottom connecting block f11, a collecting groove f12, and a guide plate f13, the collecting groove f12 is embedded in the inner position of the bottom connecting block f11, and the guide plate f13 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com