Collaborative exploitation and cyclic utilization device and method for coal bed gas and oil gas

A technology for coalbed methane and oil and gas, applied in the field of co-associated resource exploitation, can solve problems such as hidden dangers of coalbed methane safety, and achieve the effect of saving human, material and financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

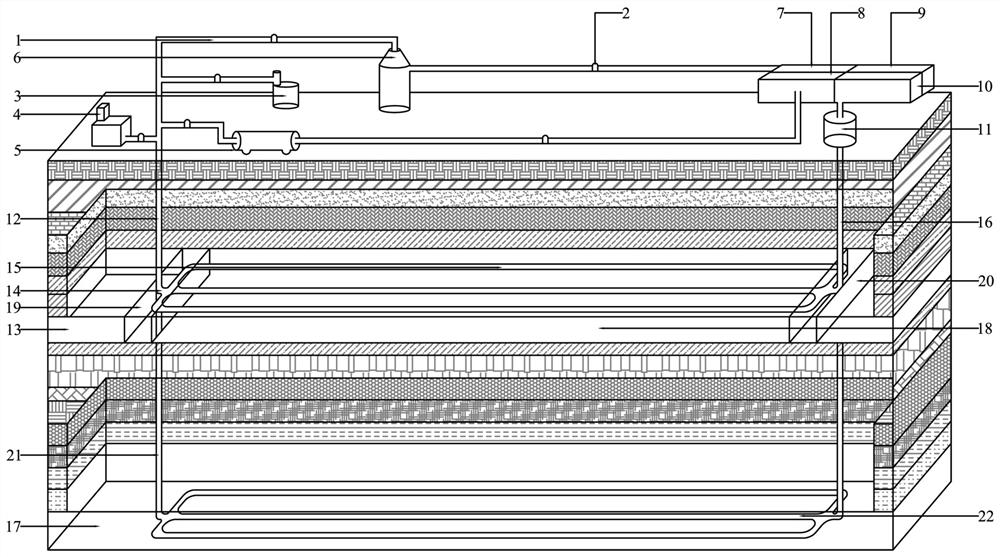

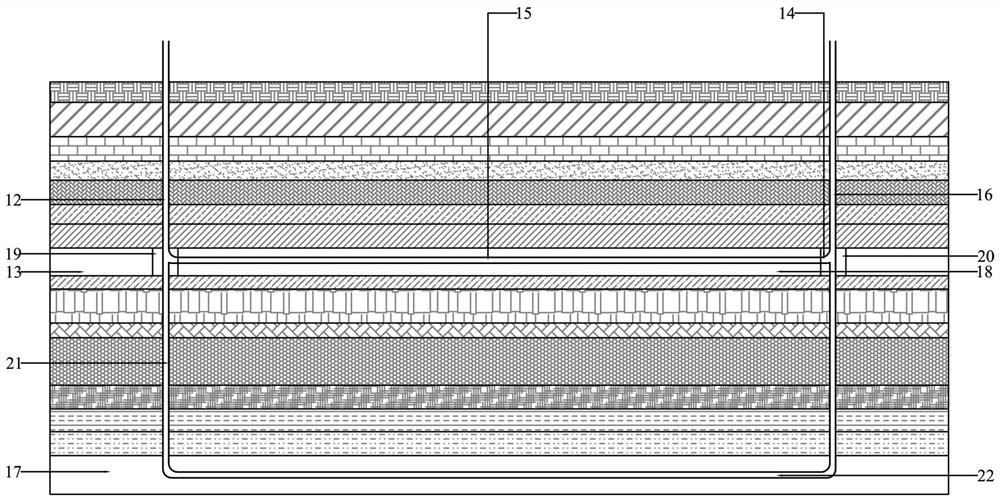

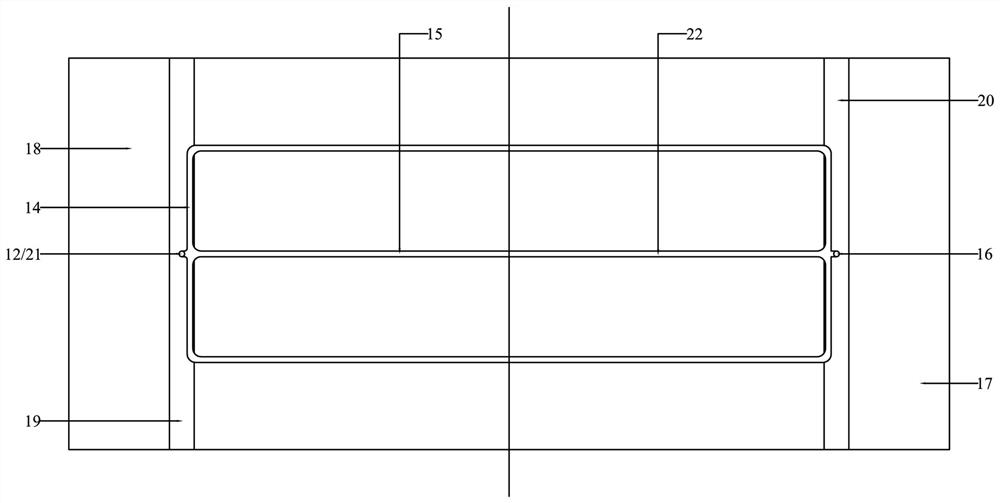

[0043] A coalbed methane + oil and gas collaborative exploitation and recycling device, comprising a cracking and sealing mechanism and a surface transfer mechanism; wherein,

[0044] The fracturing and storage mechanism includes a coalbed methane extraction device and an oil and gas extraction device; the coalbed methane extraction device includes a main input pipe 12 , a separation conveying pipe 14 , a coalbed methane fracturing and extraction joint pipe 15 and a main extraction pipe, which are connected in sequence. Union 16;

[0045] The oil and gas extraction device includes a secondary input pipe 21, a secondary separation and conveying pipe 14, an oil and gas fracturing and extraction pipe 22 and a secondary extraction pipe connected in sequence; the secondary input pipe 21 is connected with the main input pipe 12, and the two The secondary drainage pipe is connected with the main drainage pipe 16;

[0046] Wherein, the main input pipe 12 and the separation pipe 14 ar...

Embodiment 2

[0049] On the basis of embodiment 1, also include:

[0050] The first-stage carbon dioxide transmission pipe 26 and the high-temperature conduction pipe 25 are cut inside the coalbed methane fracturing and extraction joint pipe 15. A first-stage carbon dioxide flow hole 34 is provided at the tangent of the pipe wall of the cracking and drainage pipe 15, and a high-temperature flow hole 32 is provided at the tangent of the high-temperature conduction pipe 25 and the pipe wall of the coalbed methane cracking and drainage pipe 15; Flexible springs 31 are provided on both sides of the flow hole 34 in the axial direction. The other end of the flexible spring 31 is connected with a closed-cell electrode 35. The diameter of the closed-cell electrode 35 is greater than the diameter of the first-stage carbon dioxide flow hole 34; 15 is also provided with a wire tube 27 on the outside of the outer tube wall, and a wire 28 is provided in the wire tube 27; both ends of the first-stage car...

Embodiment 3

[0054] On the basis of embodiment 2, it also includes:

[0055] Between the inlet end of the CBM storage tank 6 and the separation device, between the outlet end of the CBM storage tank 6 and the inlet end of the high temperature furnace 3, between the outlet end of the CBM storage tank 6 and the inlet end of the steam furnace 4. between the inlet end of the carbon dioxide storage tank 5 and the separation device, between the outlet end of the carbon dioxide storage tank 5 and the primary carbon dioxide delivery pipe 26, and between the outlet end of the carbon dioxide storage tank 5 and the secondary carbon dioxide delivery pipe 23 Ground transfer tube 1 is connected.

[0056] The separation device includes a primary separation device and a secondary separation device connected in sequence; the primary separation device is a gas extraction separation bin, and the secondary separation device includes a coalbed methane separation bin 7, a carbon dioxide separation bin 8, an oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com