Geological storage method of industrial tail gas and supporting equipment

A technology for industrial tail gas and geological storage, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as difficult to realize, complex and cumbersome processes, and high operating costs in the chemical reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

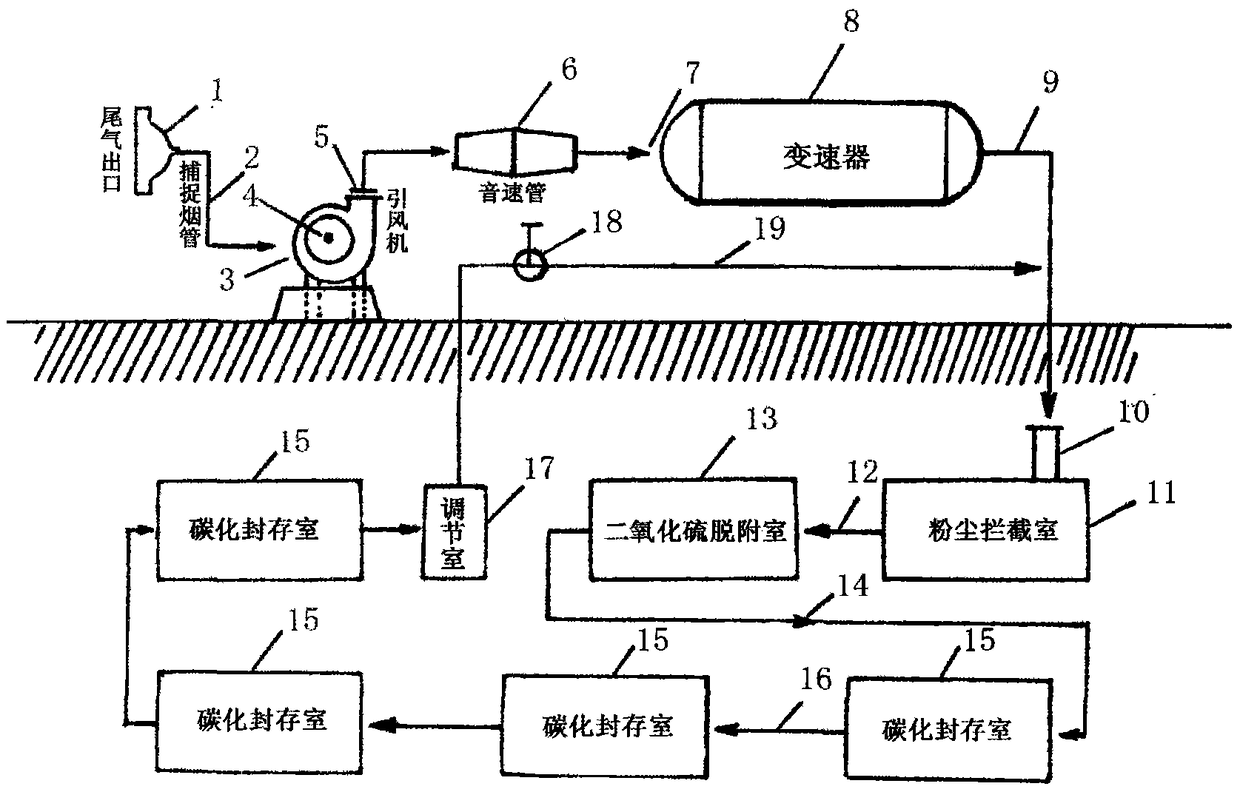

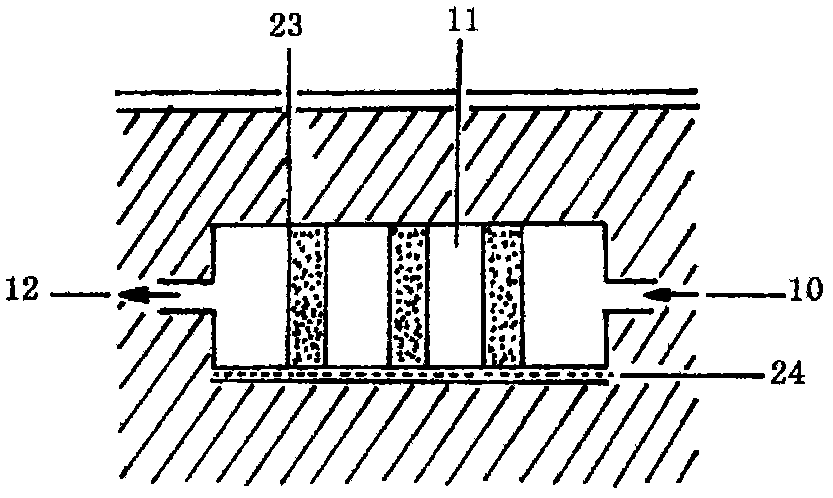

[0017] The invention is an environmental protection technology for purification and treatment of harmful industrial tail gas, which can carry out geological storage of industrial harmful gas to replace traditional discharge treatment. The device of the present invention is not complicated, and consists of two parts above ground and underground. The main function of the above ground part is to collect and capture harmful gases, and the main function of the underground part is to treat and store them. The specific implementation is described below.

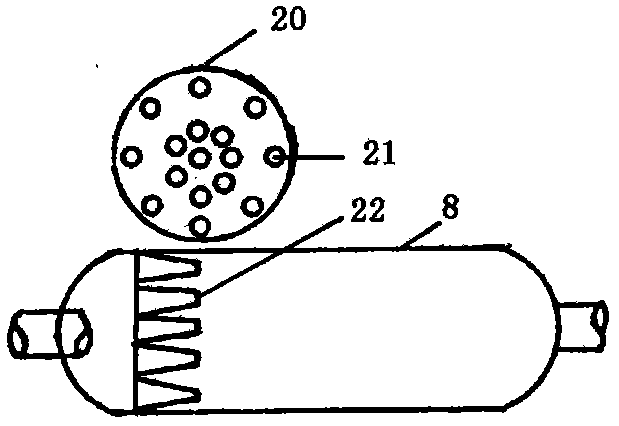

[0018] figure 1 The whole process of the treatment process is given. As shown in the figure, after the flue gas is captured by the tail gas capture port (1), the negative pressure capture pipe (2) and the induced draft fan (3, 4, 5) The expansion and contraction positive pressure sonic tube (6) is sent to the airflow speed changer (8), here, the configuration of the flue gas capture port (1) and the catch pipe (2) is set according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com