Hot dry rock supercritical carbon dioxide power generation and carbon sequestration coupling system

A carbon dioxide, coupling system technology, applied in the direction of machine/engine, production fluid, steam engine installation, etc., can solve the problems of high power consumption of compressor and loss of working medium, reduce operating power consumption, avoid efficiency loss, high expansion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further elaborated below according to specific embodiments.

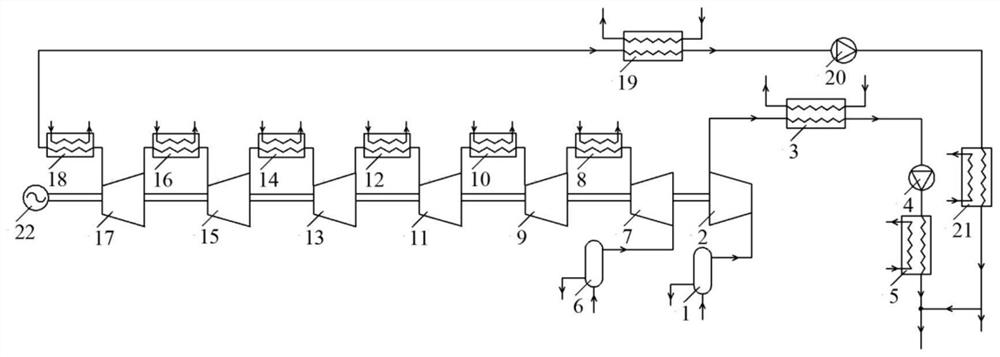

[0020] Such as figure 1 The hot dry rock supercritical carbon dioxide power generation and carbon sequestration coupling system shown includes a supercritical carbon dioxide power generation system and a carbon dioxide compression cooling system. The supercritical carbon dioxide power generation system includes a first filter 1, a steam turbine 2, and a first condenser connected in sequence 3. The first working medium pump 4, the first recooler 5, and the generator 22. The carbon dioxide compression cooling system includes a second filter 6, a first compressor 7, an intercooler, and a second condenser 19 connected in sequence , the second working medium pump 20 and the second subcooler 21, the steam turbine 2, the first compressor 7 and the generator 22 are coaxially connected, and the working medium outlet pipeline of the second subcooler 21 is divided into two paths, one way an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com