Grid line-free full-back contact solar cell module

A technology of solar cells and solar cells, applied in the field of solar cells, can solve the problems of difficult collection of electrons, difficulty in popularization, and rising costs, so as to avoid efficiency loss or process complexity, ensure long-term reliability, and save silver paste cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

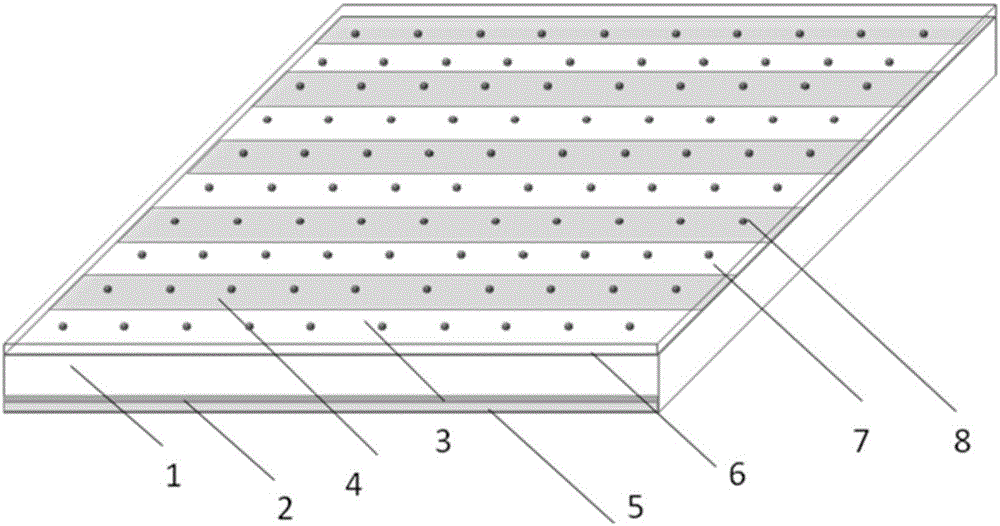

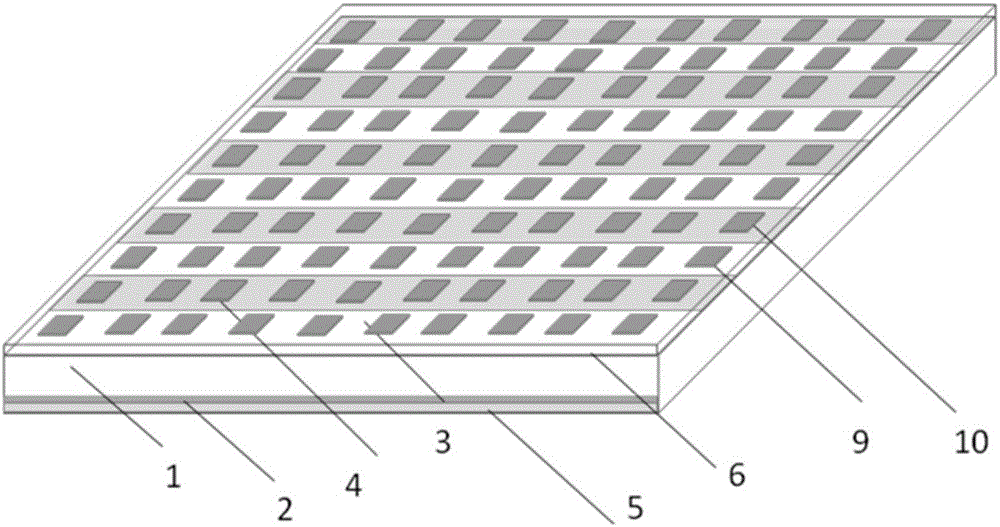

[0047] like Figure 1-6 As shown, the busbar-free full back contact solar cell assembly provided in this embodiment includes a plurality of back contact small solar cells connected in series, the back contact solar cell is cut from the back contact solar cells, and the back contact The solar battery sheet includes an n-type silicon substrate 1, and the back side of the n-type silicon substrate is provided with p+ doped regions 3 and n+ doped regions 4 arranged in parallel and alternately, and p+ doped regions 3 and n+ doped regions 4 are provided with The back passivation layer 6, the back passivation layer 6 is provided with a positive electrode contact portion 7 and a negative electrode contact portion 8, wherein the positive electrode contact portion 7 is located at the corresponding position of the p+ doped region 3 and is in contact with the p+ doped region 3 , the negative electrode contact portion 8 is located at the corresponding position of the n+ doped region 4 and i...

Embodiment 2

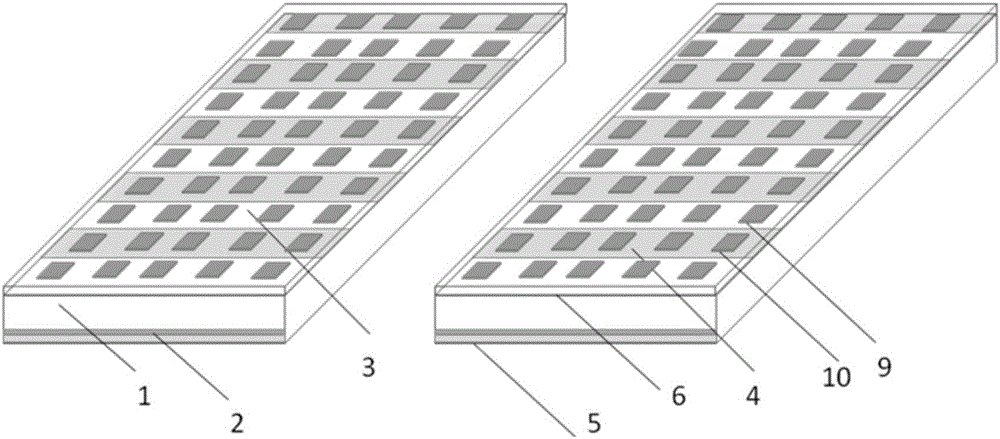

[0071] like Figure 7 As shown, the difference from Example 1 is that when two adjacent small battery pieces are connected in series, the two adjacent small battery pieces have the same structure (that is, there is no need to flip 180°), and the electrode contact portion of one small battery piece is the same as that of the adjacent battery piece. The electrode contact parts of the small batteries with the same polarity are flush, the copper wire on the positive electrode contact part is not aligned with the copper wire on the negative electrode contact part, and has a protruding end and a shortened end respectively. The protruding ends of the copper wires on two adjacent small battery pieces are connected to form series-connected battery pieces. And the welding strip is not in contact with the shortened ends of the copper wires on two adjacent small battery pieces.

[0072] That is, the welding ribbon is used to weld the protruding end of the copper wire connected to the neg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com