Pre-reinforcing process for vertical shaft penetrating through confined water layer

A technology of confined water layer and confined water, which is applied in shaft equipment, water supply equipment, wellbore lining, etc., can solve problems such as waste, prevent water gushing and sand gushing, prevent safety instability, and solve safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following detailed description is given in conjunction with the accompanying drawings.

[0054] The invention provides a method for constructing a shaft in a confined water layer based on non-drop drainage, which adopts the method of pre-reinforcement and then excavation for continuous operation, so that the shaft can pass through the confined water layer and avoid water gushing caused by the action of the confined water. phenomenon of sand.

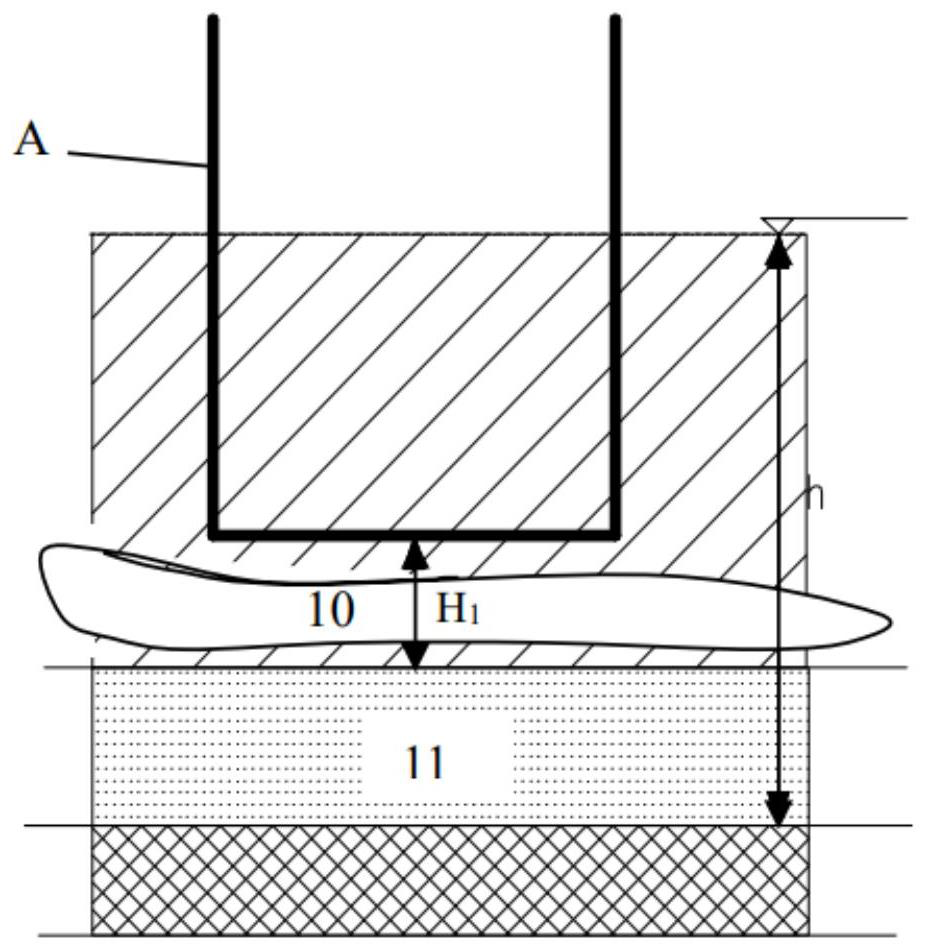

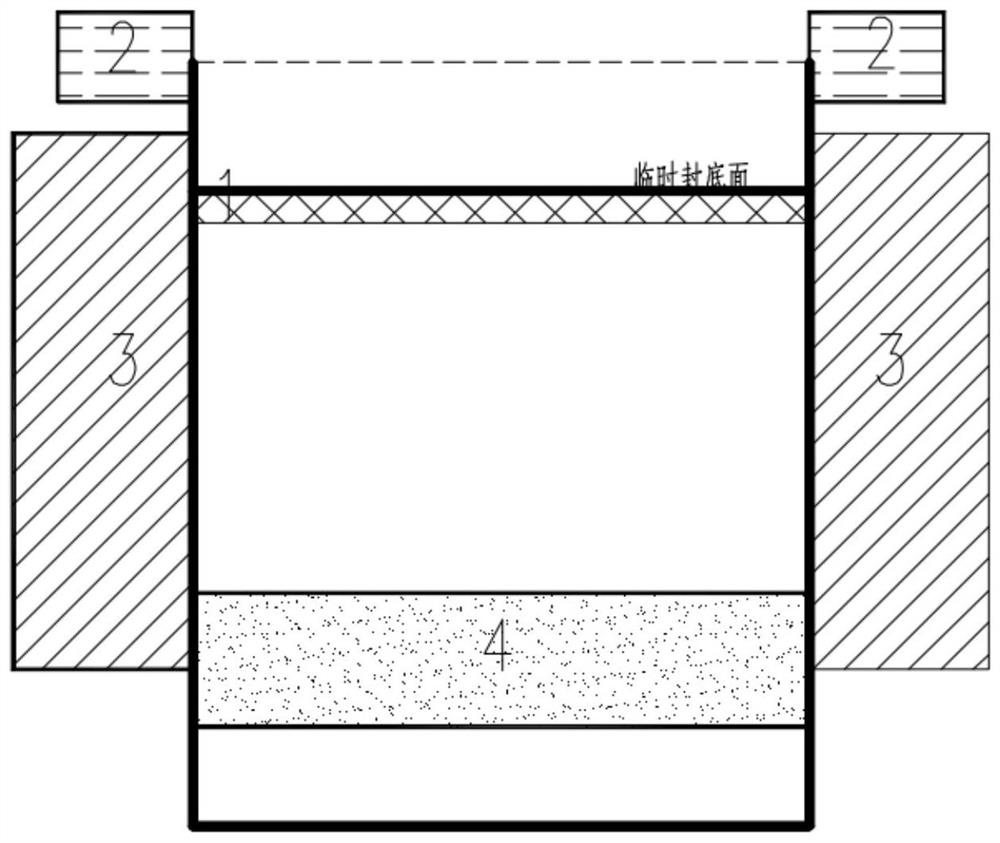

[0055] The principle of the present invention is as follows: figure 2 As shown, the water-proof and bottom-sealing reinforcement is realized by artificial grouting, an artificial water-proof reinforcement structure is formed at the bottom of the shaft, and a closed longitudinal reinforcement structure is formed in the peripheral range of the shaft to resist water pressure.

[0056] During trenchless, γH 1 =γ ω h;

[0057] Among them, H 1 is the thickness of the impermeable layer after the shaft is excavated, γ is the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com