Wind cap dredging and slag collecting equipment for power station boiler

A technology for power station boilers and collection equipment, applied in lighting and heating equipment, removal of solid residues, combustion methods, etc., can solve the problems of insufficient fuel combustion, blockage, affecting ventilation performance, etc., to improve efficiency and avoid cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

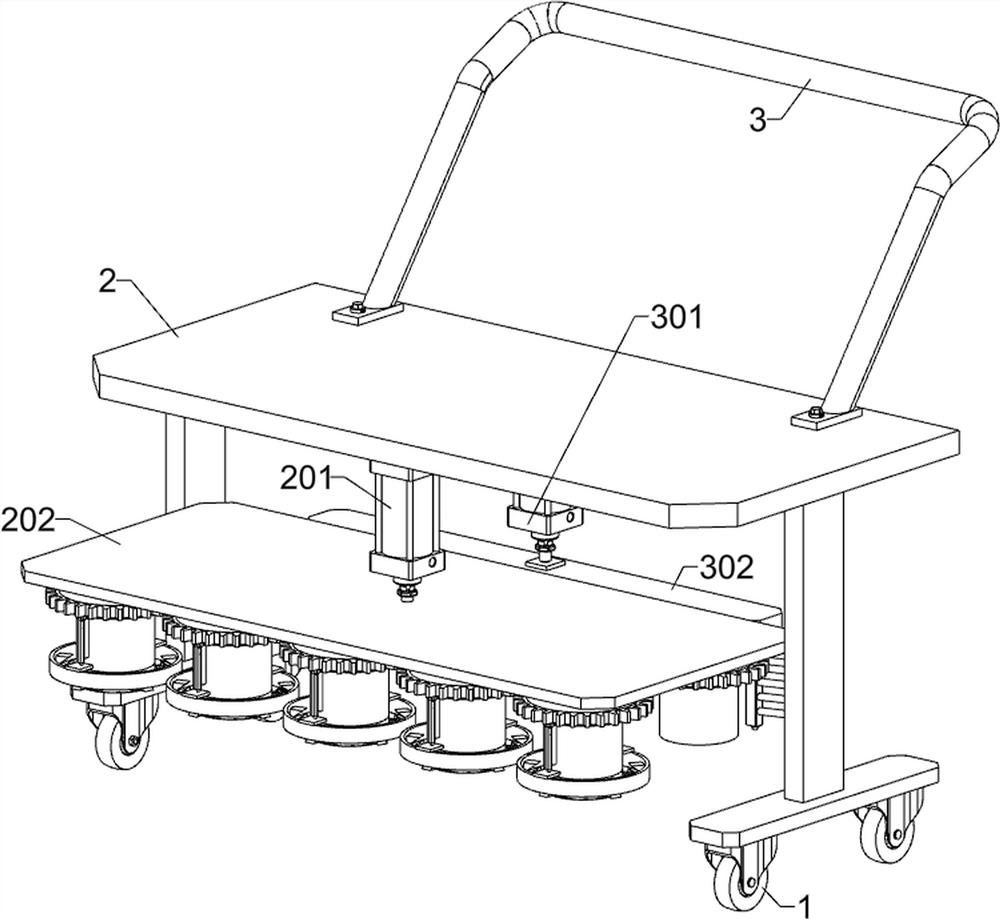

[0033] A wind cap dredging and slag collecting equipment for power station boilers, such as Figure 1-13 As shown, it includes a moving wheel 1, a bottom frame 2, a handle 3, a dredging unit and a slag cleaning unit; the top of the four moving wheels 1 is connected with a bottom frame 2; the upper right part of the bottom frame 2 is connected with a handle 3; the bottom The left part of the frame 2 is connected with a dredging unit; the middle part of the bottom frame 2 is connected with a slag cleaning unit.

[0034] The dredging unit includes a first air cylinder 201, a first installation plate 202 and a dredging mechanism 203; a first air cylinder 201 is fixedly connected to the left part of the inner and lower side of the chassis 2; the telescopic end of the first air cylinder 201 is fixedly connected to a first installation plate 202; Five dredging mechanisms 203 are fixedly connected to the lower side of the first mounting plate 202 at equal distances.

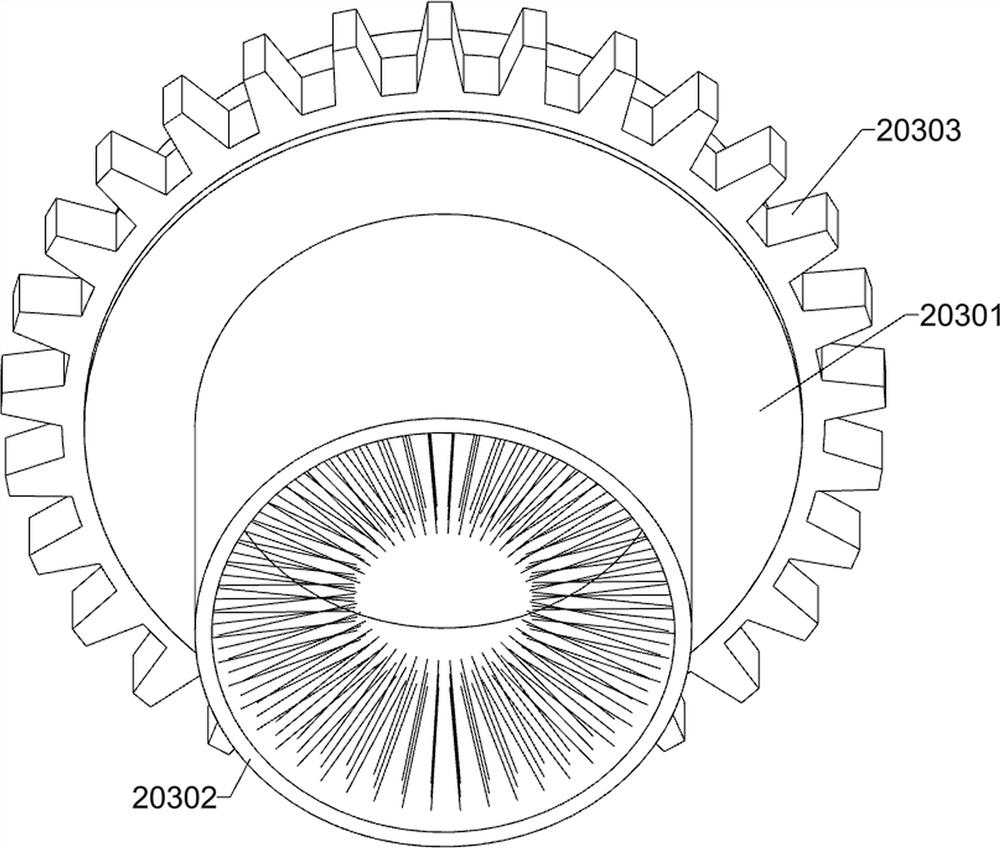

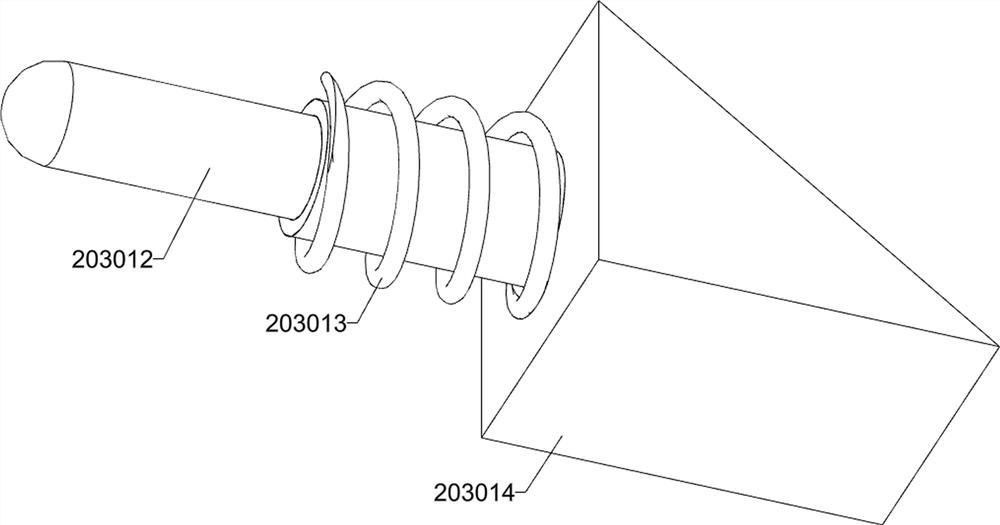

[0035] The frontm...

Embodiment 2

[0044] On the basis of Example 1, as figure 1 and Figure 14-16 As shown, it also includes a slag collection unit; the right part of the bottom frame 2 is connected with a slag collection unit; , drive shaft 405, seventh installation plate 406, third cleaning rod 407, second gear 408, eighth installation plate 409, fourth cylinder 4010, ninth installation plate 4011, collection box 4012, guide rod 4013, tenth installation The plate 4014, the eleventh mounting plate 4015 and the third rack 4016; the eighth mounting plate 409 is fixedly connected to the front side of the chassis 2; the third cylinder 401 is fixedly connected to the right part of the inner and lower side of the chassis 2; The telescopic end is fixedly connected with a sixth mounting plate 402; the lower side of the sixth mounting plate 402 is bolted with a second electric sliding rail 403; the second electric sliding rail 403 is slidably connected with a second electric sliding block 404; the second electric sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com