Energy storage system and method facilitating maintenance and replacement of internal battery pack

An energy storage system and battery pack technology, applied in the field of energy storage systems, can solve problems such as inconvenient maintenance, and achieve the effects of convenient adjustment, convenient use, and reduction of space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

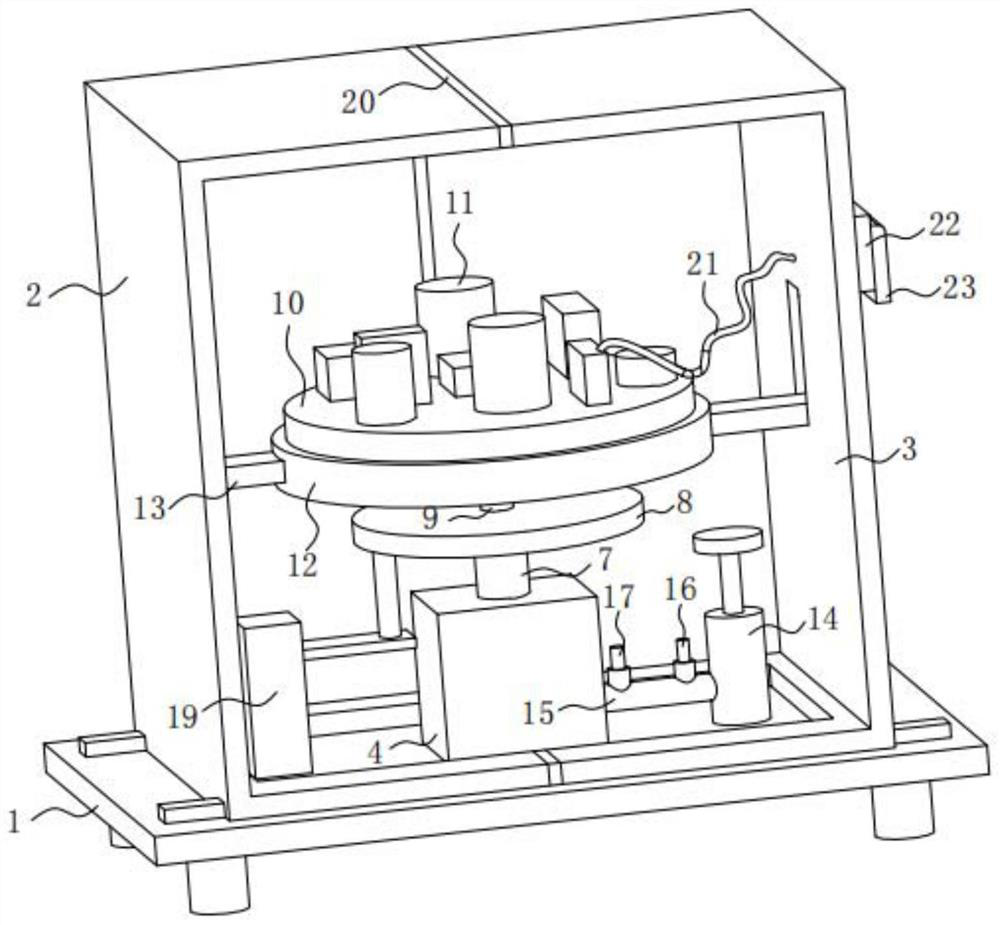

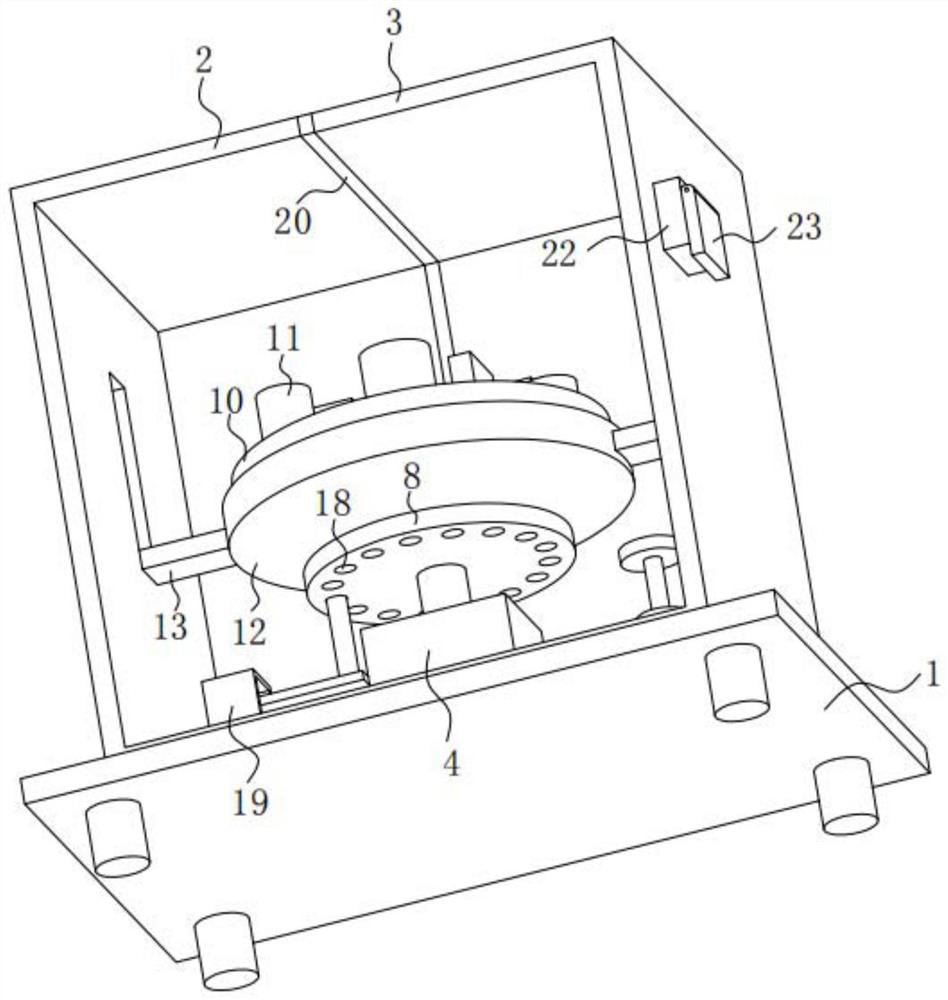

[0033] Please refer to Figure 1-Figure 5 As shown, the energy storage system that facilitates maintenance and replacement of the internal battery pack includes: a base 1;

[0034] a first frame body 2, the bottom of the first frame body 2 is arranged on the top of the base 1, and the top of the base 1 is arranged with a second frame body 3;

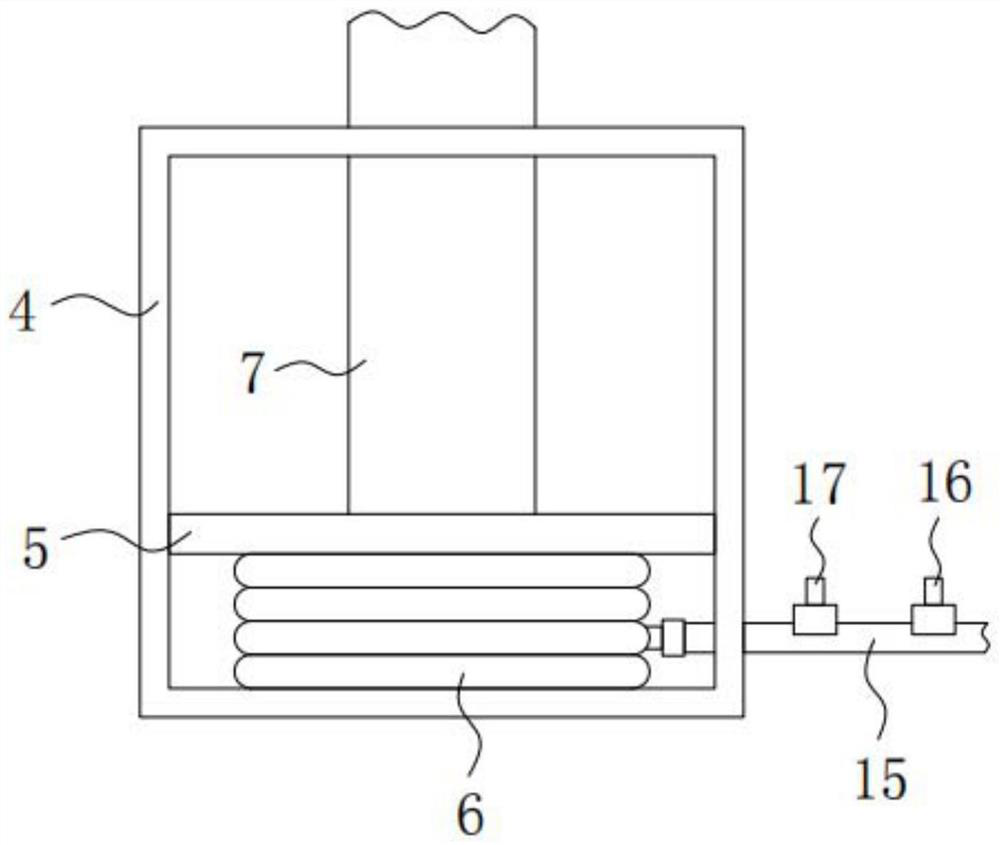

[0035] A fixed frame 4, the bottom of the fixed frame 4 is arranged on the top of the base 1, an adjustment plate 5 is arranged between the two sides of the inner wall of the fixed frame 4, and the bottom of the adjustment plate 5 is connected to the fixed frame 4 An airbag 6 is arranged between the bottoms of the inner walls, and a fixing column 7 is arranged on the top of the adjusting plate 5. The top of the fixing column 7 penetrates the fixing frame 4 and extends to the top of the fixing frame 4. The top of the column 7 is provided with a first circular plate 8, the top of the first circular plate 8 is provided with a connecting sh...

no. 2 example

[0054] Please refer to Figure 6-7 Specifically, the difference between the energy storage system provided by the second embodiment of the present application, which is convenient for maintenance and replacement of the internal battery pack, is that a winding structure 24 is provided on the right side of the second frame body 3, and the The reeling structure 24 includes a connecting frame 241, a front surface of the inner wall of the connecting frame 241 is provided with a rotating rod 242, an outer surface of the rotating rod 242 is provided with a reel 243, and the power cord 21 is wound around the reel 243 , a mounting block 244 is provided on the outer surface of the rotating rod 242 , and a torsion spring 245 is provided between the mounting block 244 and the front surface of the inner wall of the engaging frame 241 .

[0055] A cover plate 246 is movably connected to the front of the engaging frame 241 , a positioning groove 247 is arranged at the back of the cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com