Multi-particle implantation end effector for continuous puncture

An end effector and multi-particle technology, applied in the field of medical devices, can solve problems affecting the treatment effect, bending deformation of puncture needles, and deformation of tissues and organs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described:

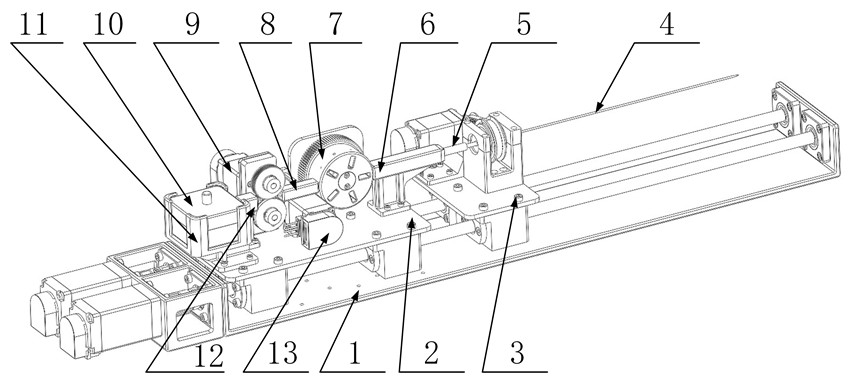

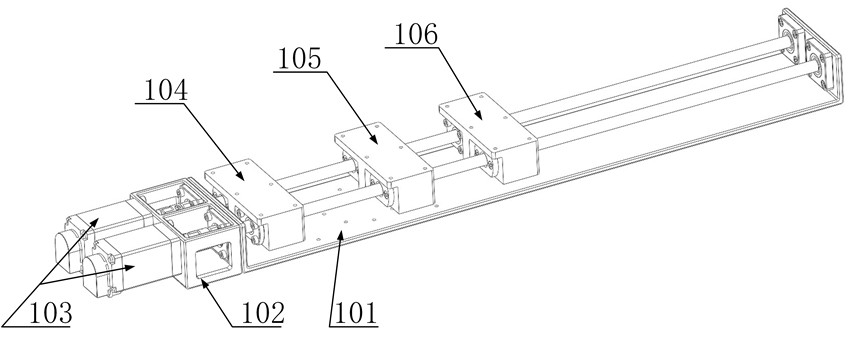

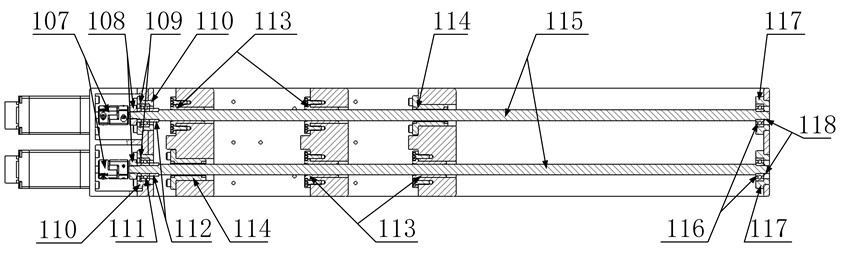

[0042] like figure 1 , figure 2 , Figure 4 , Figure 8 As shown in the figure, a multi-particle implantation end effector for continuous puncture is characterized in that: the double-screw front slider 106 in the driving mechanism 1 is connected with the puncture needle release mechanism 3 through screws, and the puncture needle The clip-releasing mechanism 3 fixes the outer puncture needle 4, the outer puncture needle 4 cooperates with the inner puncture needle 5, the end of the inner puncture needle 5 is in contact with the pre-particle guide bracket 6, and the pre-particle guide bracket 6 is in contact with the porous The rotary particle clip mechanism 7 is connected, and the porous rotary particle clip mechanism 7 is driven and rotated by the porous rotary particle clip driving mechanism 13, and the porous rotary particle clip mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com