Continuous stripping process for open pit coal mine under loess loess loess landform

A technology of open-pit coal mine and stripping process, which is applied in underground mining, open-pit mining, surface mining, etc. It can solve the problems of mine fuel consumption increase, loess volume increase, and poor adaptability, so as to reduce truck transportation distance and reduce fuel consumption. Consumption, the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are to explain rather than limit the present invention.

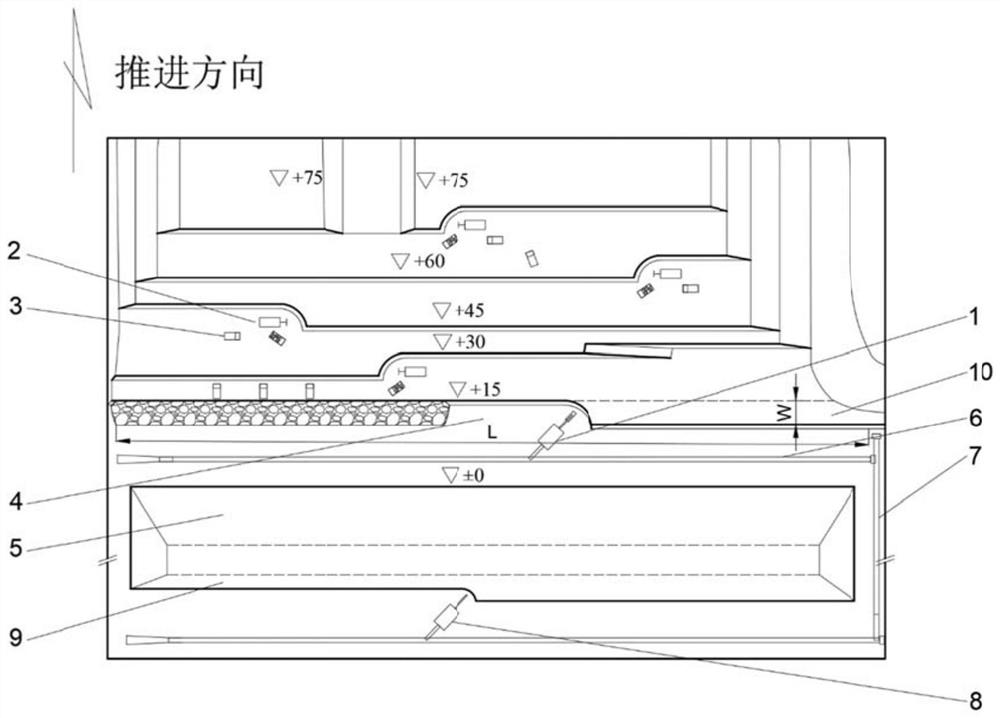

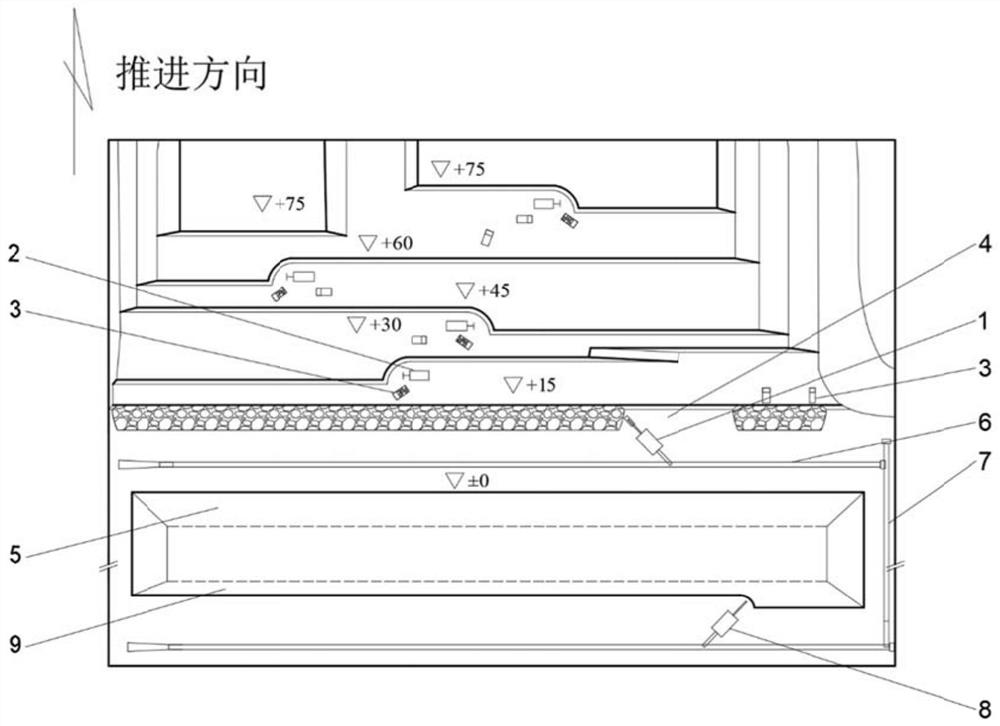

[0028] The invention discloses a continuous stripping process for an open-pit coal mine under the loess mao landform. figure 1 , 2 , including the following steps:

[0029] Step 1: The upper loess of the working gang 5 of the open-pit coal mine is continuously stripped by the bucket excavator 1, and the upper loess is transported by the working gang belt conveyor 6 located in the working gang 5 and the end gang belt conveyor 7 located in the end gang. Go to the dumper 8 at 9 places in the inner dumping ground, and use the dumper 8 to discharge the loess;

[0030] After blasting, the hard rock layer in the lower part of the open-pit coal mine work group 5 adopts a single bucket excavator 2-truck 3 intermittent mining process, and the lower hard rock layer is transported by the truck 3 to the inner dump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com