Composite fireproof anti-corrosion cable bridge

A cable tray and composite technology, applied in electrical components, fire rescue, etc., can solve problems such as internal temperature rise, change of connection mode, lack of heat dissipation windows, etc., to increase heat dissipation, improve safety performance, and avoid direct contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

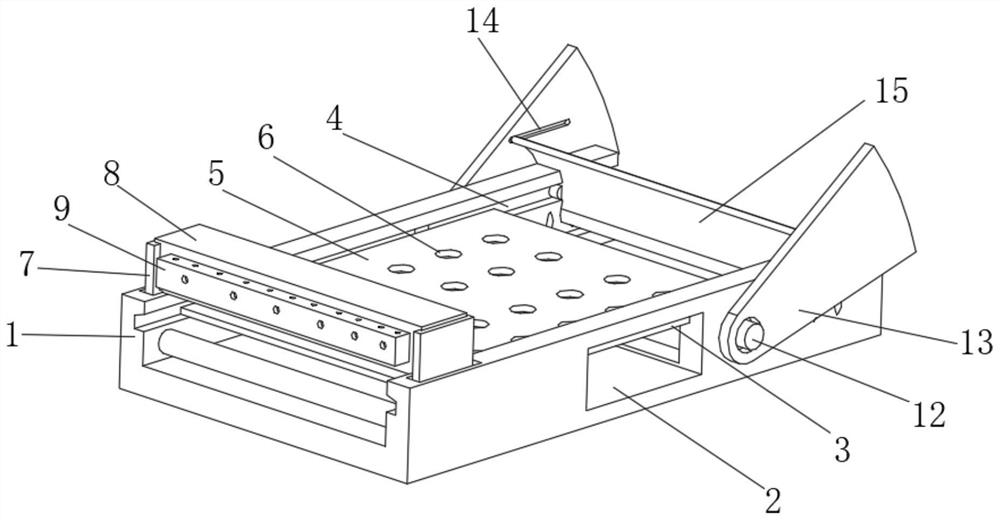

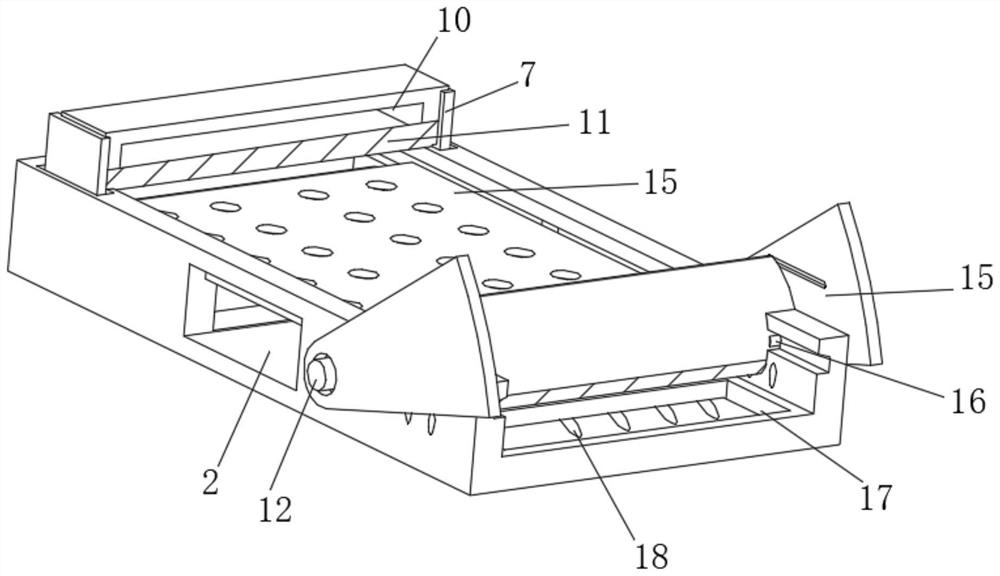

[0031]As shown in Figures 1, 2 and 4 of the composite fire-proof and anti-corrosion cable tray, the present invention provides a technical solution: the composite fire-proof and anti-corrosion cable tray includes a fixed base frame 1, and the left and right sides of the outer surface of the fixed base frame 1 are provided with Side groove 2, the inner surface of the side groove 2 is slidably connected with the connecting plate 3, the left and right sides of the inner surface of the fixed chassis 1 are fixedly connected with the fixed rails 4, and the opposite sides of the two fixed rails 4 are slidably connected to each other. The dust plate 5, the bottom of the dust plate 5 and the inner surface of the fixed base frame 1 is rotatably connected with a fixing mechanism 6, and the top of the fixed base frame 1 is slidably connected with a lifting plate 7. There are two lifting plates 7, and the two lift The top of the board 7 is fixedly connected with a shielding interference box...

Embodiment 2

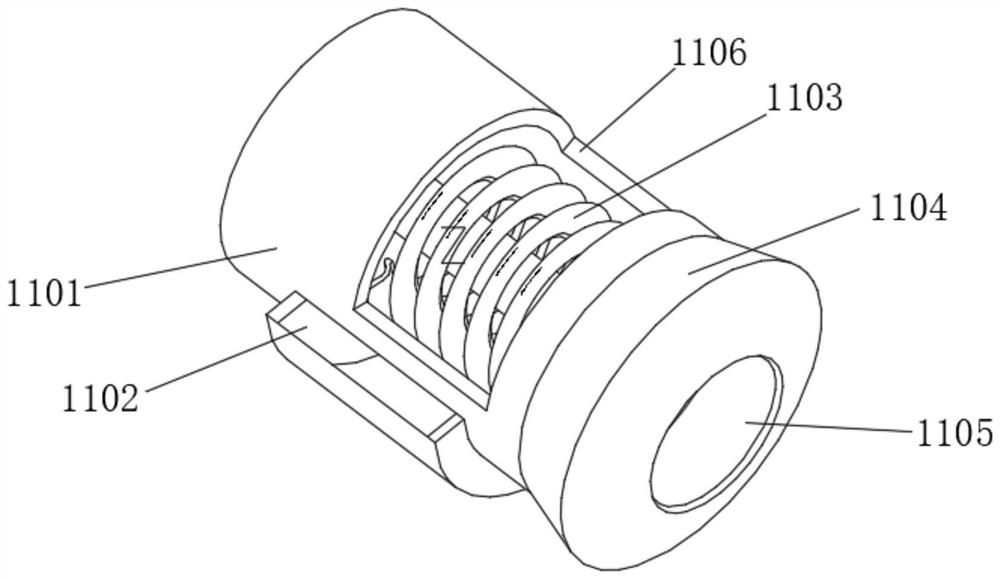

[0036] As shown in Figures 1-3 and 5-6 of the composite fire-proof and anti-corrosion cable tray, the present invention provides a technical solution: the composite fire-proof and anti-corrosion cable tray, the ventilation mechanism 11 includes a fixed cylinder 1101, and the outer surface of the fixed cylinder 1101 interferes with the shielding The outer surface of the box 8 is movably connected, the outer surface of the fixed cylinder 1101 is provided with a dark groove, the inner surface of the dark groove is connected with the air transmission cylinder 1102, the inner surface of the fixed cylinder 1101 is rotatably connected with a rotating shaft, and the outer surface of the rotating shaft is uniformly fixed A flat fan blade 1103 is connected.

[0037] A connection sleeve 1104 is fixedly connected to the right end of the fixing cylinder 1101 , a connection port 1105 is formed on the outer surface of the connection sleeve 1104 , and an observation window 1106 is formed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com