Down-proof sewing process

A technology of anti-drilling and craftsmanship, applied in the field of clothing production, can solve the problems of down drilling, rough workmanship, and low quality, and achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

[0023] Example;

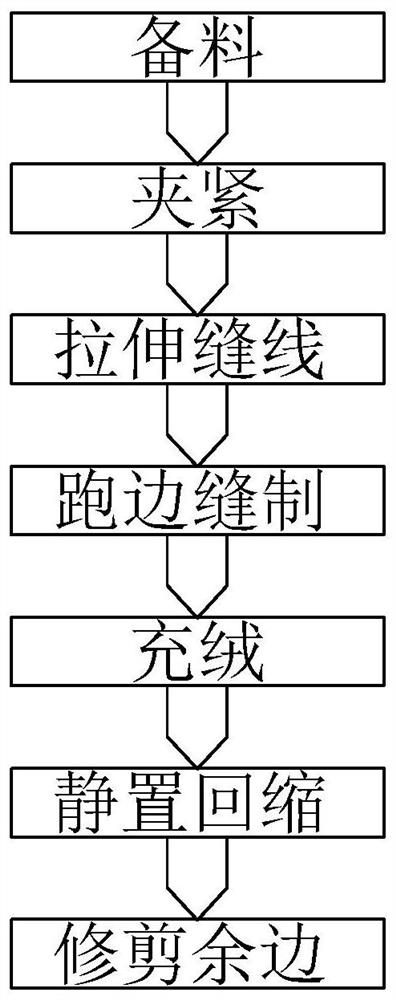

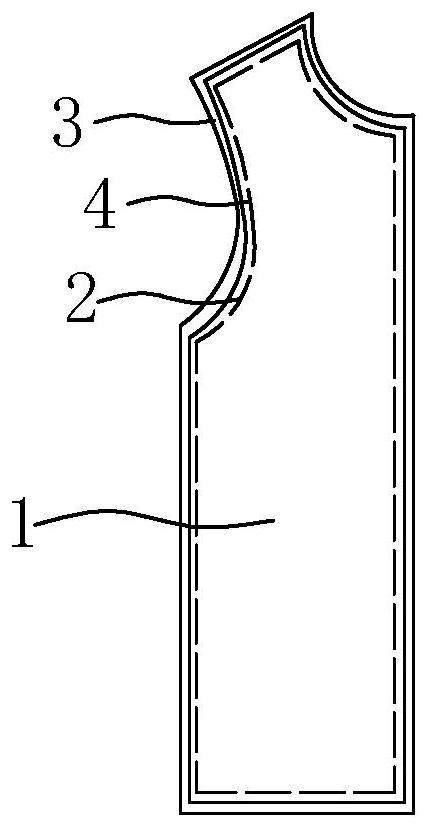

[0024] refer to Figure 1 to Figure 2 , an anti-drill down sewing process, comprising the following steps:

[0025] S11, prepare materials, select fabrics, cut the selected fabrics into an upper fabric layer and a lower fabric layer according to a predetermined template, and select elastic cotton and polyester yarns as fabric yarns.

[0026] S12, clamping, overlapping the upper fabric layer and the lower fabric layer to form a garment piece 1, and clamping it along the edge of the garment piece 1 with a clamp.

[0027] S13, stretch the suture, tighten the garment piece 1 after clamping, pass the taut garment piece 1 through the template to keep it in a taut state and clamp it on the template machine, and then stretch the fabric to traverse the thread , so that the length of the fabric line is extended to 1.05-1.20 times the ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com