Ink-jet channel adjusting system and multi-channel ink-jet printer

An adjustment system and inkjet technology, applied in printing and other directions, can solve the problems of decreased inkjet accuracy and unsatisfactory printing effect of printers, and achieve the effect of convenient and precise adjustment and reliable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

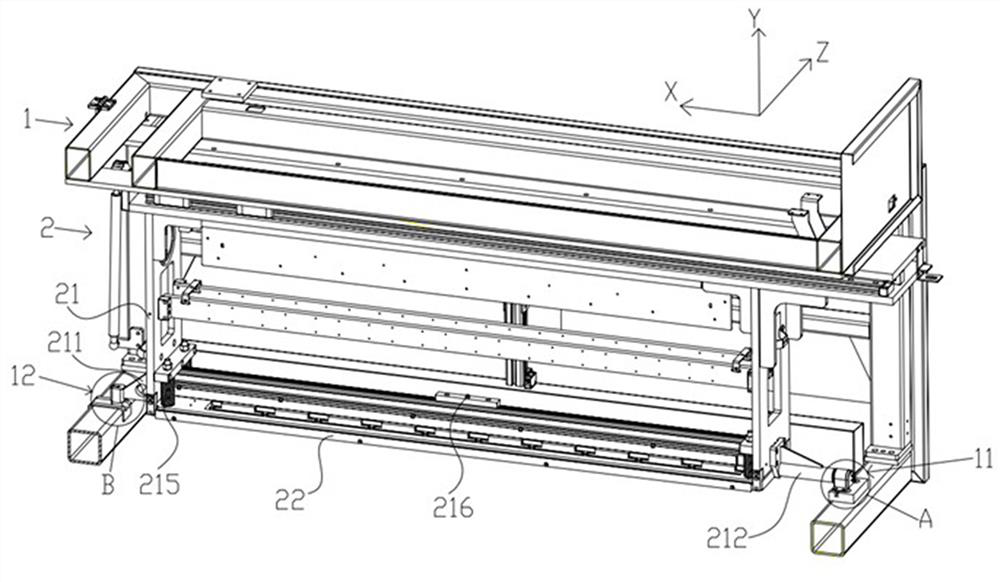

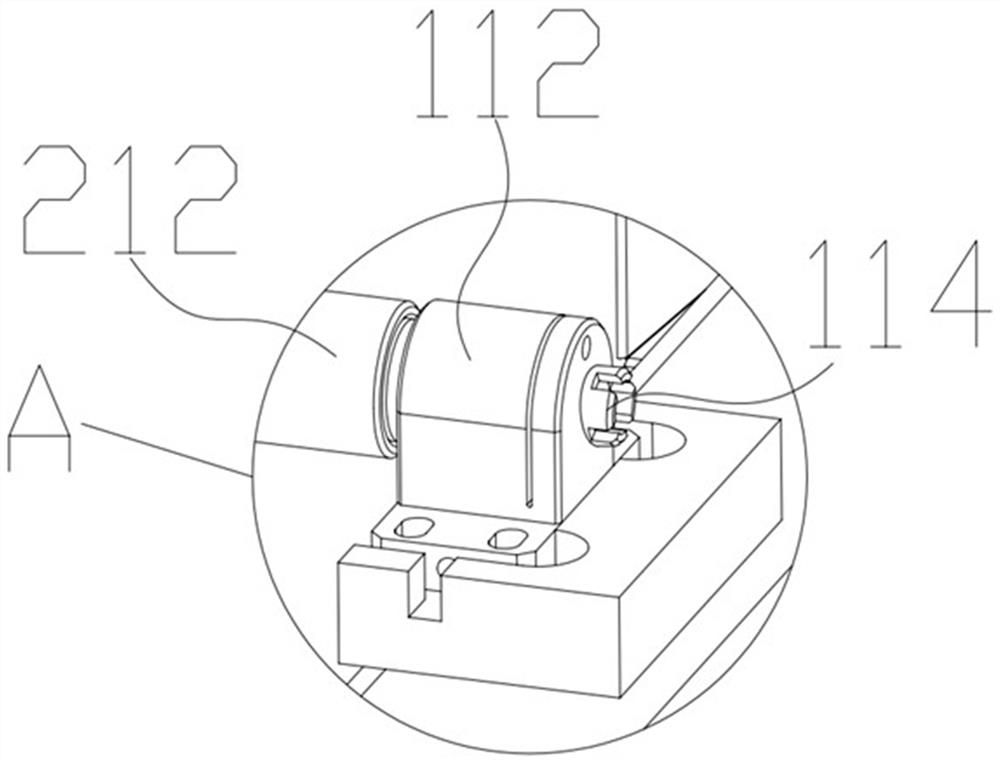

[0032] see figure 1 , the present invention provides a technical solution: an inkjet channel adjustment system, including a frame 1 and an inkjet channel 2, the inkjet channel 2 includes an inkjet fixing frame 21 and an inkjet bottom plate 22, and the inkjet channel 2 slides with the frame 1 connect.

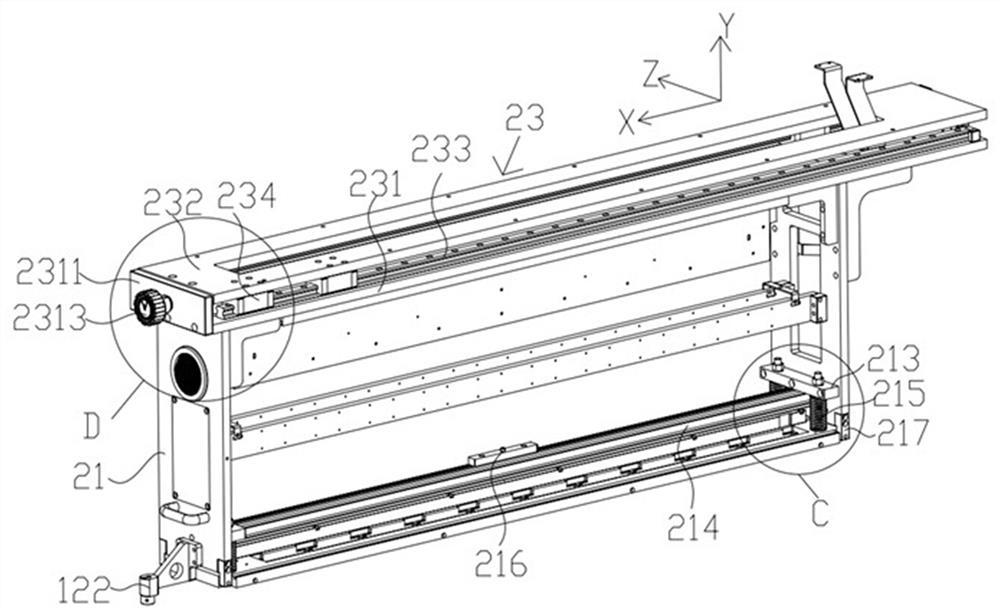

[0033] like Figure 1-2 and Figure 10As shown, there is a sliding positioning structure 23 between the upper end of the inkjet fixing frame 21 and the frame 1 for facilitating the maintenance of the inkjet channel 2 by pulling and pulling, and the sliding positioning structure 23 includes a sliding plate 231 fixedly connected with the inkjet fixing frame 21 , the limit plate 232 fixedly connected with the frame 1, the first X-axis sliding guide rail 233 fixed on the sliding plate 231 and the second X-axis sliding guide fixed on the limit plate 232, the sliding plate 231 and the limit The position plate 232 is disposed upside down in the Y-axis direction, and the first X-axis...

Embodiment 2

[0045] like Figure 11 As shown, the multi-channel inkjet printer includes a conveying platform 3 arranged below the inkjet channel 2, several racks 1 and inkjet channels 2 using the inkjet channel adjustment system, and each inkjet channel 2 is arranged in parallel on the rack 1 and perpendicular to the conveying platform 3. Through the inkjet channel adjustment system, it is convenient for each inkjet channel 2 to achieve the effect of coplanarity between the inkjet channels 2. First, the deviation of each inkjet channel 2 on the X axis is less than 0.3 mm, and the second is that each inkjet channel 2 has a deviation of less than 0.3 mm. 2 are perpendicular to the conveying platform 3, and the third is that the distance between each inkjet channel 2 and the conveying platform 3 on the Y axis is consistent, and the deviation is less than 0.2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com