Tensioning method for vertical prestressed steel strand of concrete continuous beam

A prestressed steel strand, vertical prestressing technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. The effect of avoiding broken wires, ensuring quality and increasing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

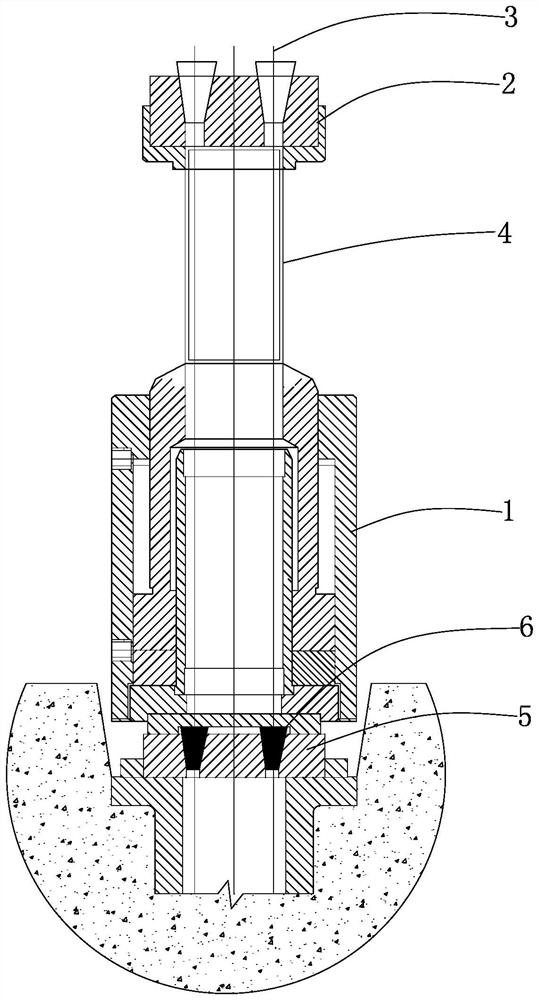

[0014] like figure 1 As shown, during the primary tensioning, a steel sleeve 4 is set on the prestressed steel strand 3 between the tensioning jack 1 and the tool anchor 2, and the length of the steel sleeve is greater than the height of the secondary tensioning bracket. The depth of the anchoring groove is to improve the bite mark position of the tool anchor on the steel strand; the tension jack 1 pushes the steel sleeve 4 upward, and the prestressed steel strand 3 is stretched to the design length. The clip 6 is knocked into the hole, and the prestressed steel strand 3 is anchored to complete one tension;

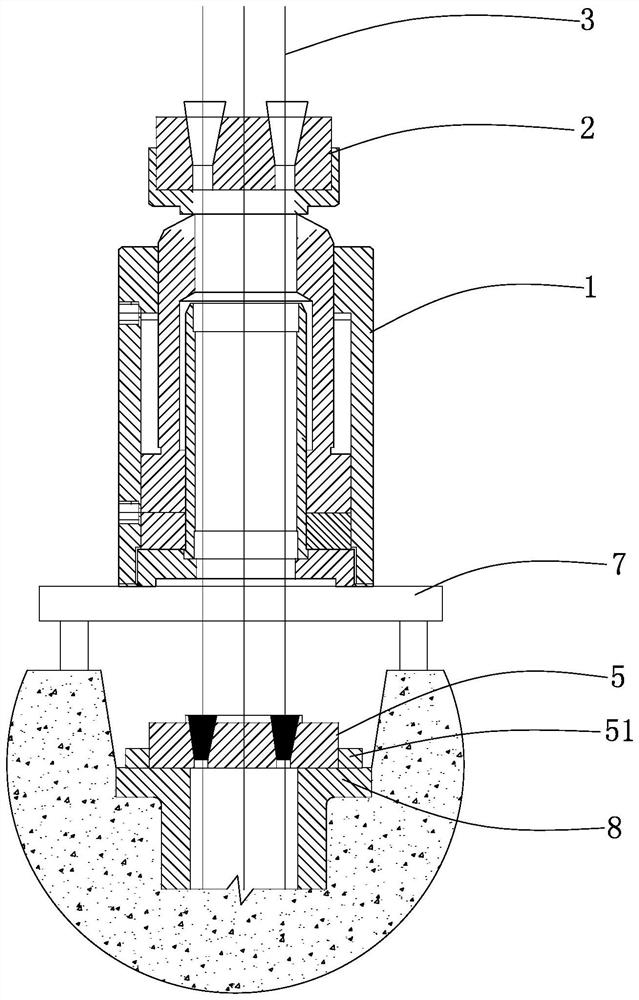

[0015] like figure 2 As shown, during the secondary tensioning, the steel sleeve is removed, and a tensioning bracket 7 is set under the tensioning jack 1. The bottom of the tensioning jack 1 is supported on the tensioning bracket 7, and the top is directly in contact with the tool anchor 2, and Ensure that the bite mark on the steel strand 3 is located above the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com