Cable doubling adjustable wire guiding wheel device

An adjustable and guide wheel technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of many broken wires, prone to broken wires, and reduce work efficiency, so as to improve product quality, The effect of reducing production costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

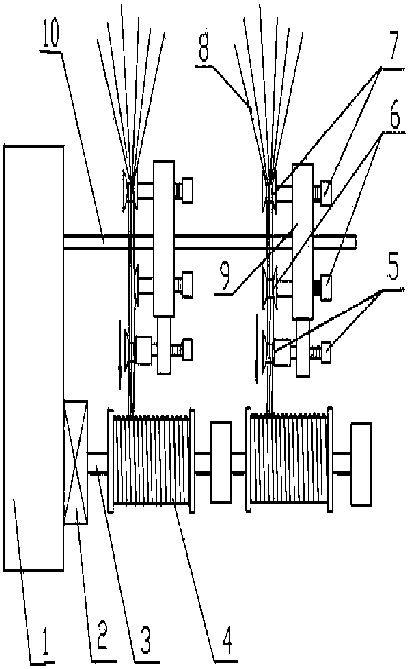

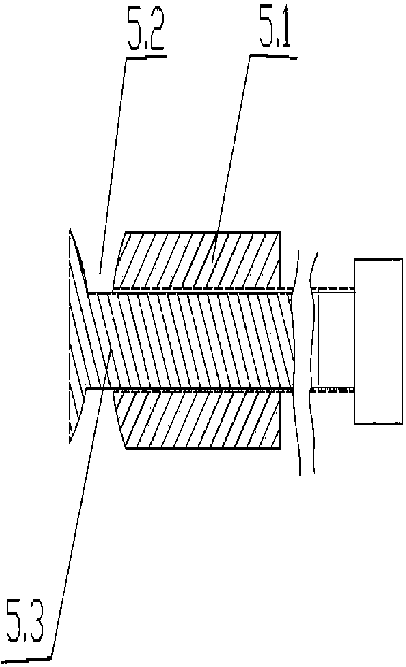

[0009] An adjustable guide wheel device for cable paralleling, including a frame 1, a motor 2, a drive shaft 3, a bobbin 4, a wire harness wheel, and an adjustable clamp seat 9, and is characterized in that the motor 2 and the cable screw rod 10 are installed on On the frame 1, the drive shaft 3 is connected to the output shaft of the motor 2, the bobbin 4 is installed on the drive shaft 3, the adjustable clamp seat 9 is connected with the wire screw rod 10 through threads, the front wire pulley 7 and the rear wire pulley 6 Fixed in the adjustable clip seat 9, the adjustable clip seat 9 is also provided with a guide wheel 5, the guide wheel 5 is composed of a nut head 5.1 and a screw rod 5.3, the nut head 5.1 is sleeved on the screw rod 5.3, and the inner end of the screw rod 5.3 The end portion and the nut head 5.1 are arc-shaped, and form an adjustable wheel groove 5.2, which is located between the bobbin 4 and the rear beam wheel 5. The multi-strand braided wires 8 on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com